Intelligent automatic adhesive dispensing device

An automatic dispensing and intelligent technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of slow production speed, uneven tin and less tin, and scrapped batch products, so as to improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

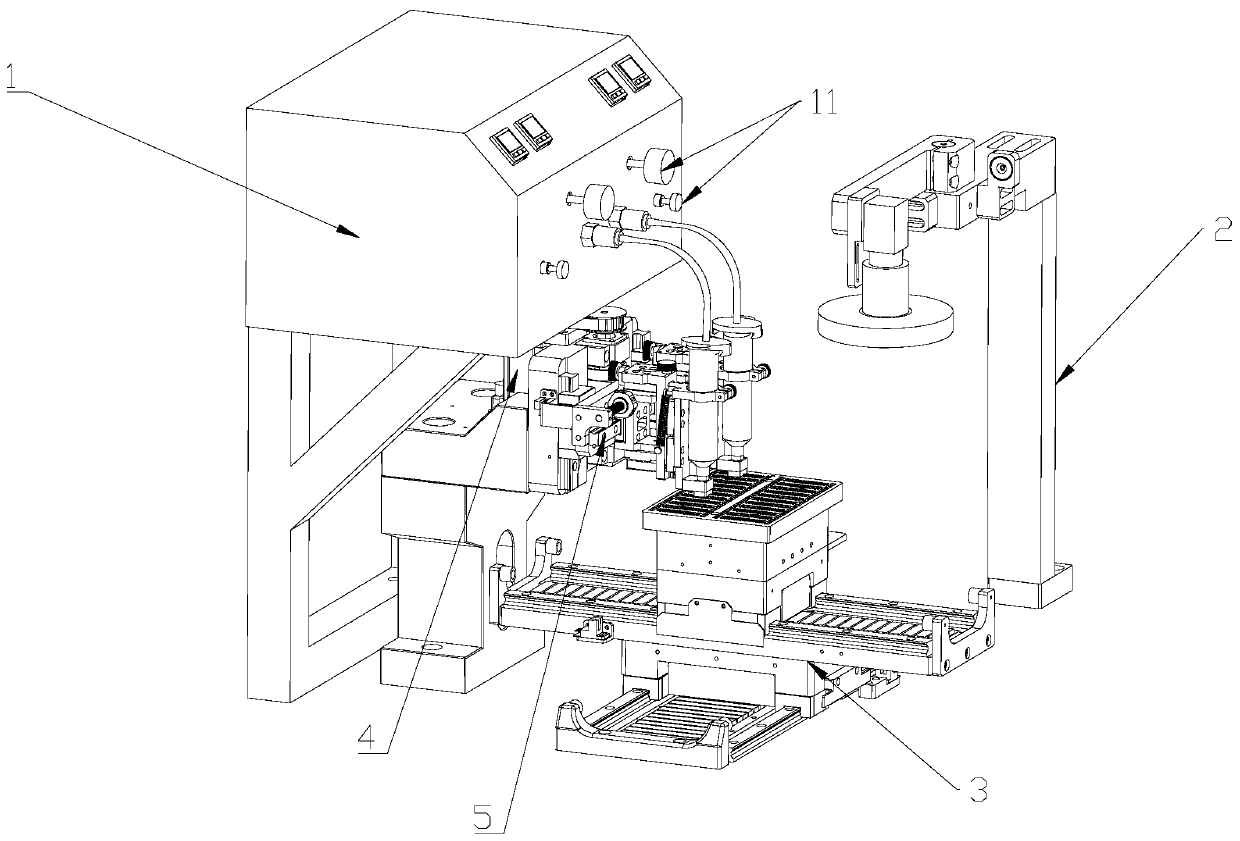

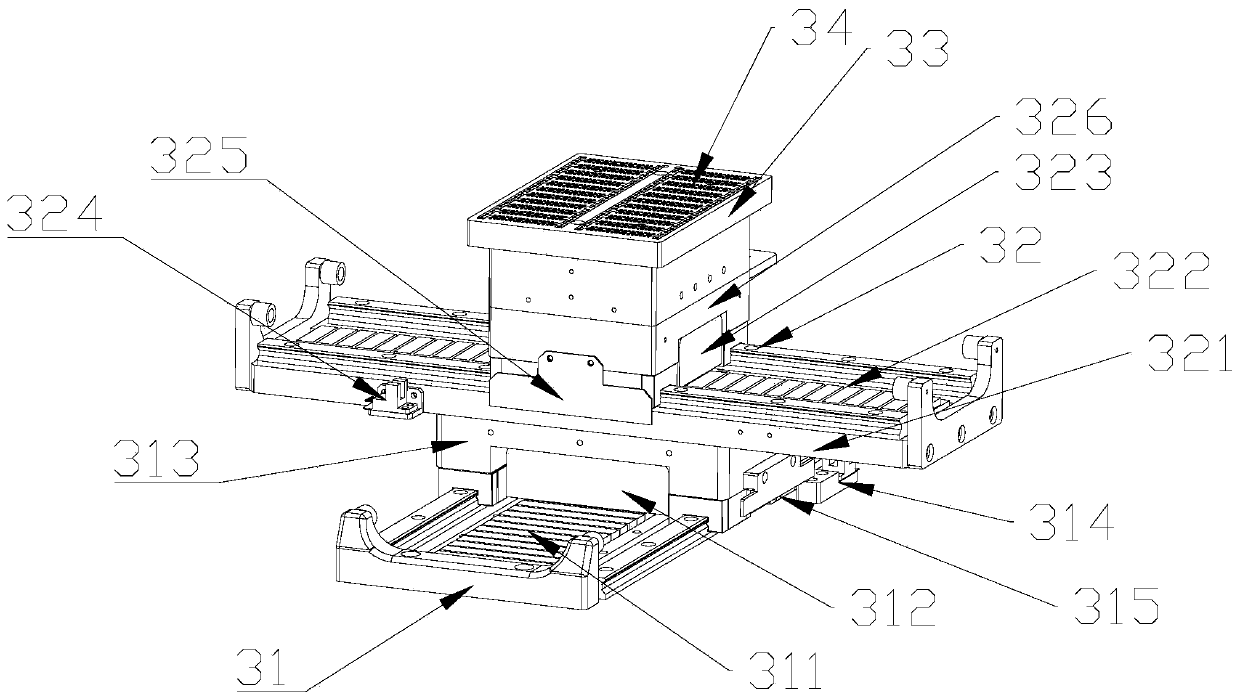

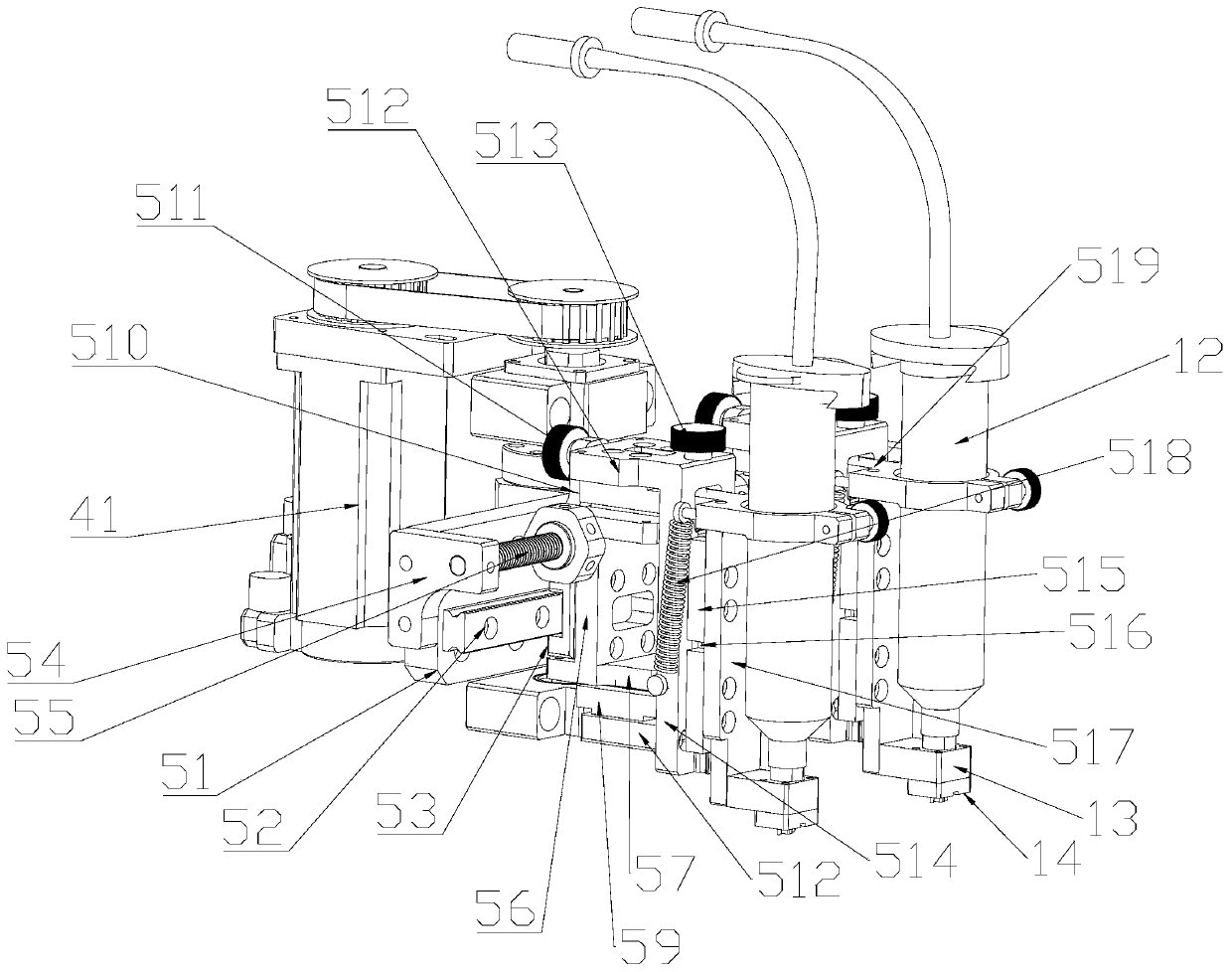

[0025] see Figure 1-7As shown, the present invention relates to an intelligent automatic dispensing device, including a dispensing assembly 1, a servo motor module 4, a control assembly, a detection assembly 2, a frame platform 33 for placing a tablet 34, and a driving connection with the frame platform 33 And the two-axis linear module 3 that drives the frame platform 33 to move along the X and Y directions of the space. The dispensing assembly 1 includes an air tank, a number of solder paste syringes 12 with built-in solder paste, and the number of solder paste syringes 12 corresponds to the precision pressure regulating valve 11, wherein the gas tank communicates with the solder paste syringe 12 through the precision pressure regulating valve 11, wherein the two-axis linear module 3 drives the frame platform 33 to directly below the solder paste syringe 12, And the servo motor module 4 is drivingly connected to the solder paste syringe 12, and drives the solder paste syrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com