Clamping system for fastening a cooling unit to an encircling supporting element of a caterpillar-type casting machine, and method for fastening/releasing a cooling unit to/from an encircling supporting element of a caterpillar-type casting machine

A technology of supporting elements and cooling blocks, which is applied in the direction of connecting components, mechanical equipment, thin plate connections, etc., can solve the problems of bolt element damage and high cost, and achieve the effect of firm clamping system, safe and reliable clamping system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

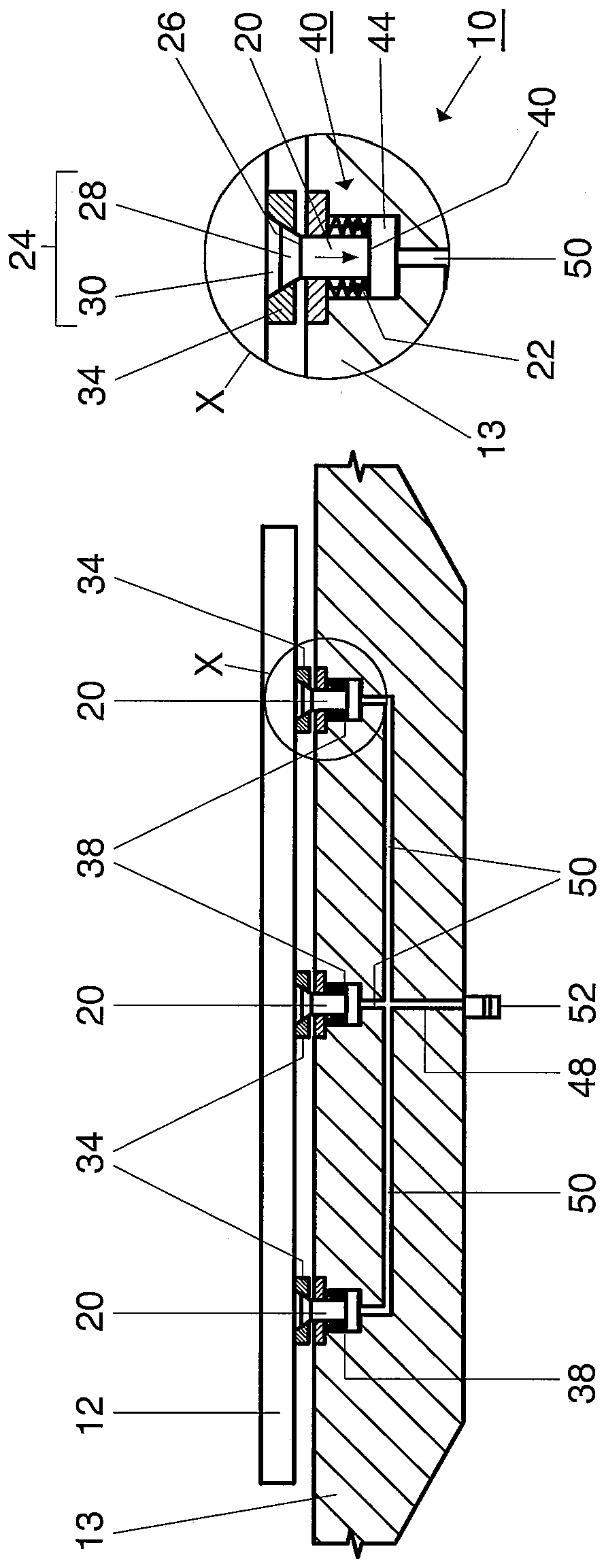

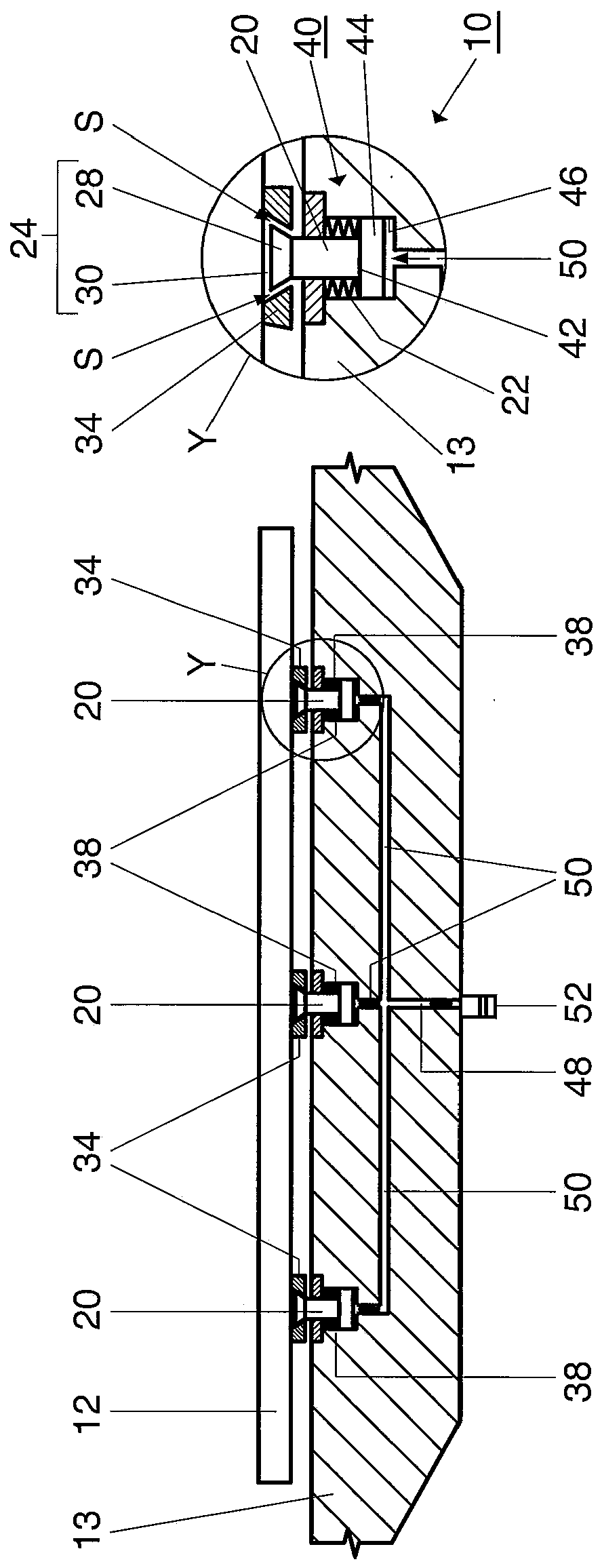

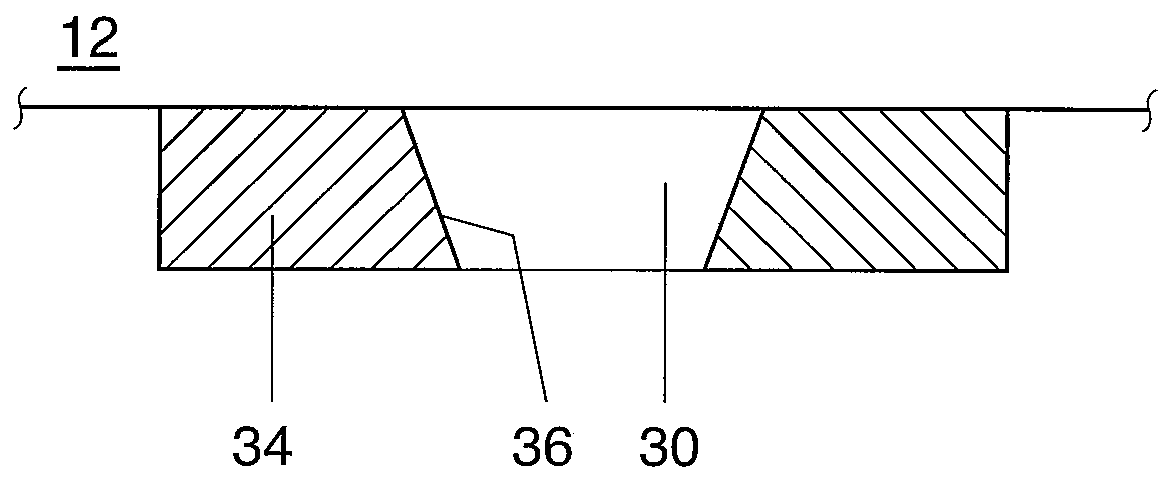

[0028] Refer below Figure 1 to Figure 6 A preferred embodiment of the clamping system 10 according to the invention is explained for fastening the cooling block 12 on the surrounding support element 13 of the crawler casting machine 14 . In the figures, identical features are provided with the same reference numerals. It should be pointed out separately at this point that the figures are only shown in simplified form and in particular not to scale. For such a clamping system 10 it is also provided, as will be explained separately below, that when the cooling block 12 is fastened to the support element 13, the cooling block 12 can be detached from the crawler casting machine 14 again with The clamped state of the cooling block 12 is released in a simple manner.

[0029] figure 1 and figure 2 Each shows a side view of a cooling block 12 and an associated support element 13 of a crawler casting machine 14 in which the clamping system 10 according to the invention is used. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com