External opening handle support mounting pre-hanging structure

A technology of opening handle and handle bracket, which is applied in the field of automobile body, can solve the problems that the original bullet feet 42 are easy to break, require high manufacturing precision, and affect pre-hanging, etc., so as to avoid assembly difficulties, improve user comfort, and improve production. and the effect of assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

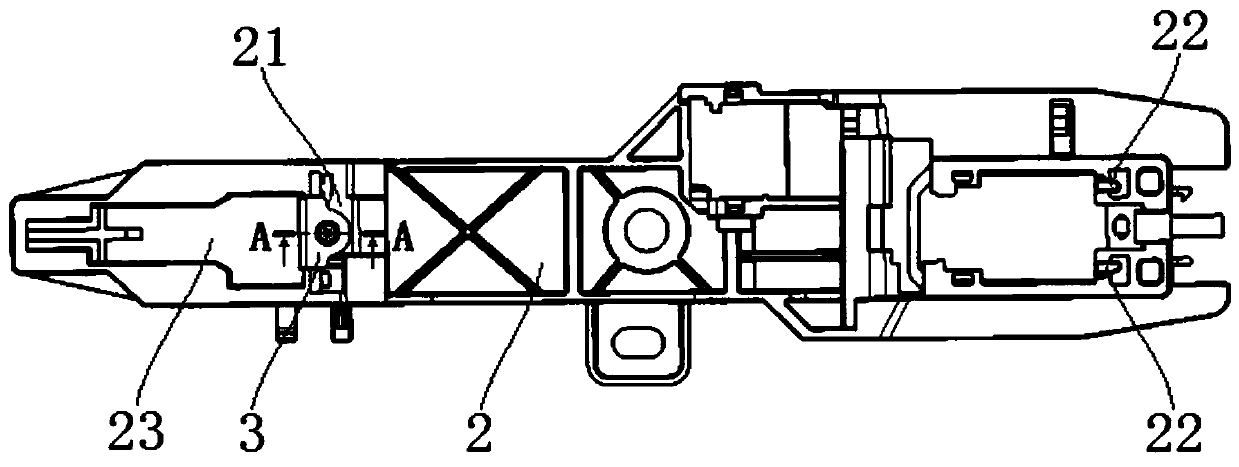

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0032] In this specification, "inward" refers to a direction toward the interior of the vehicle body, and "outer" refers to a direction toward the exterior of the vehicle body.

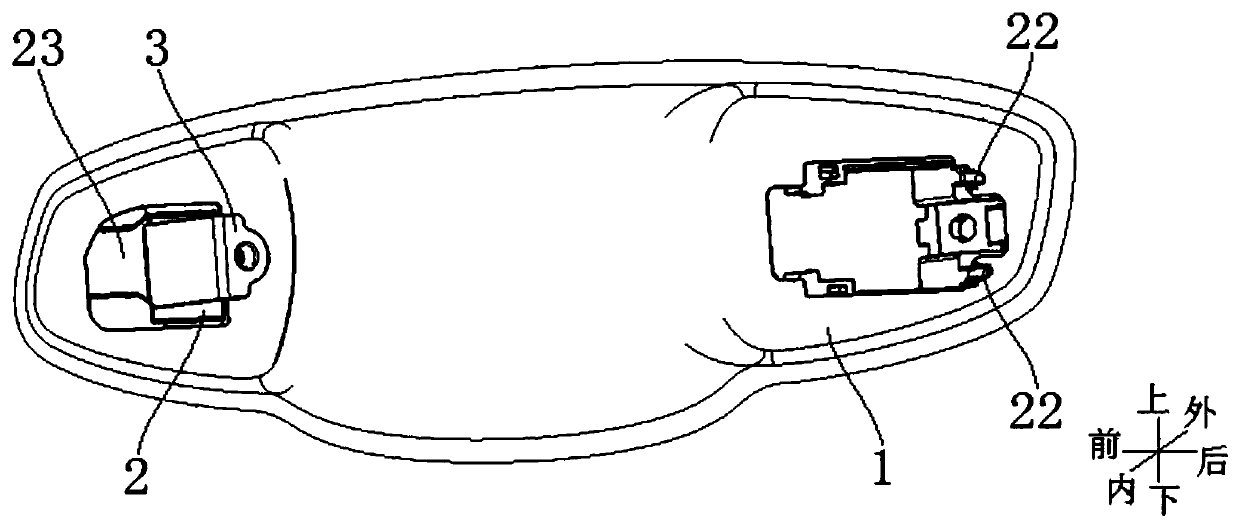

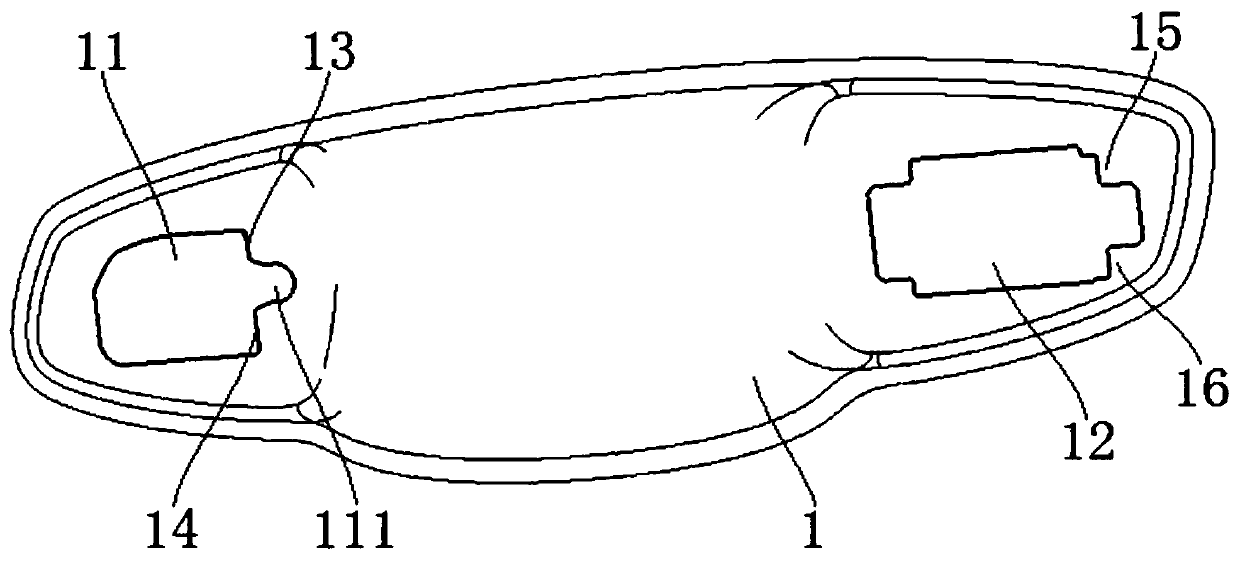

[0033] see Figure 1 to Figure 7 The installation pre-hanging structure of an outward opening handle bracket includes a car door outer panel 1, a handle bracket 2 located on the inner side of the car door outer panel 1 and connected with it, and is characterized in that it also includes a car door outer panel 1 The pre-hanging rubber pad 3 matched with the handle bracket 2. The pre-hanging rubber pad 3 not only cooperates with the handle bracket 2, but also cooperates with the door outer panel 1, so that the pre-hanging of the handle bracket 2 can be realized.

[0034] The door outer panel 1 is provided with a front matching hole 11 and a rear matching hole 12; the front pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com