Telescopic pumping pipe

A pumping tube and telescopic technology, which is applied to supply devices, manufacturing tools, buildings, etc., can solve the problems of pumping tube disturbance and deformation, and achieve the effect of reducing the overall cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

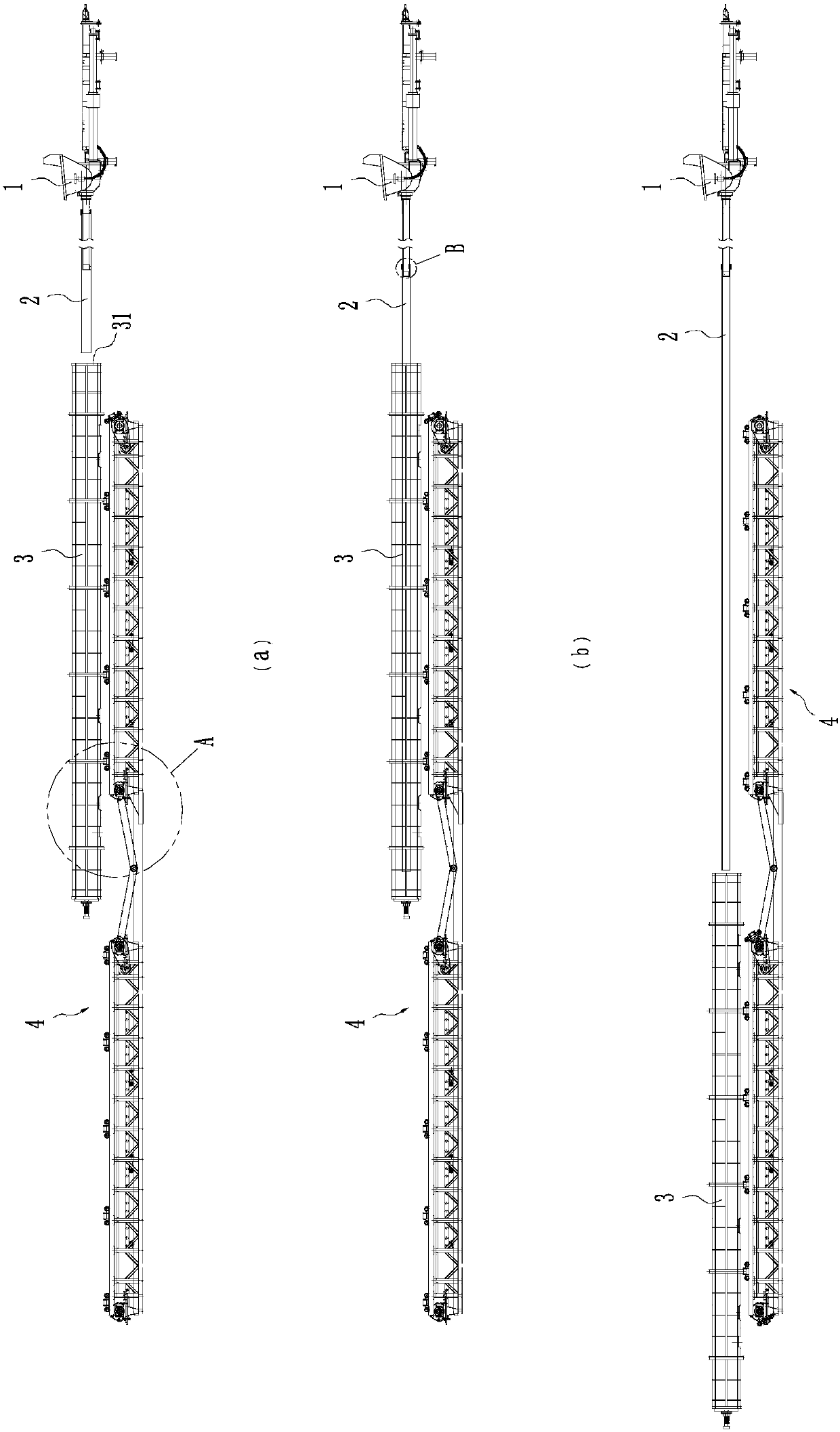

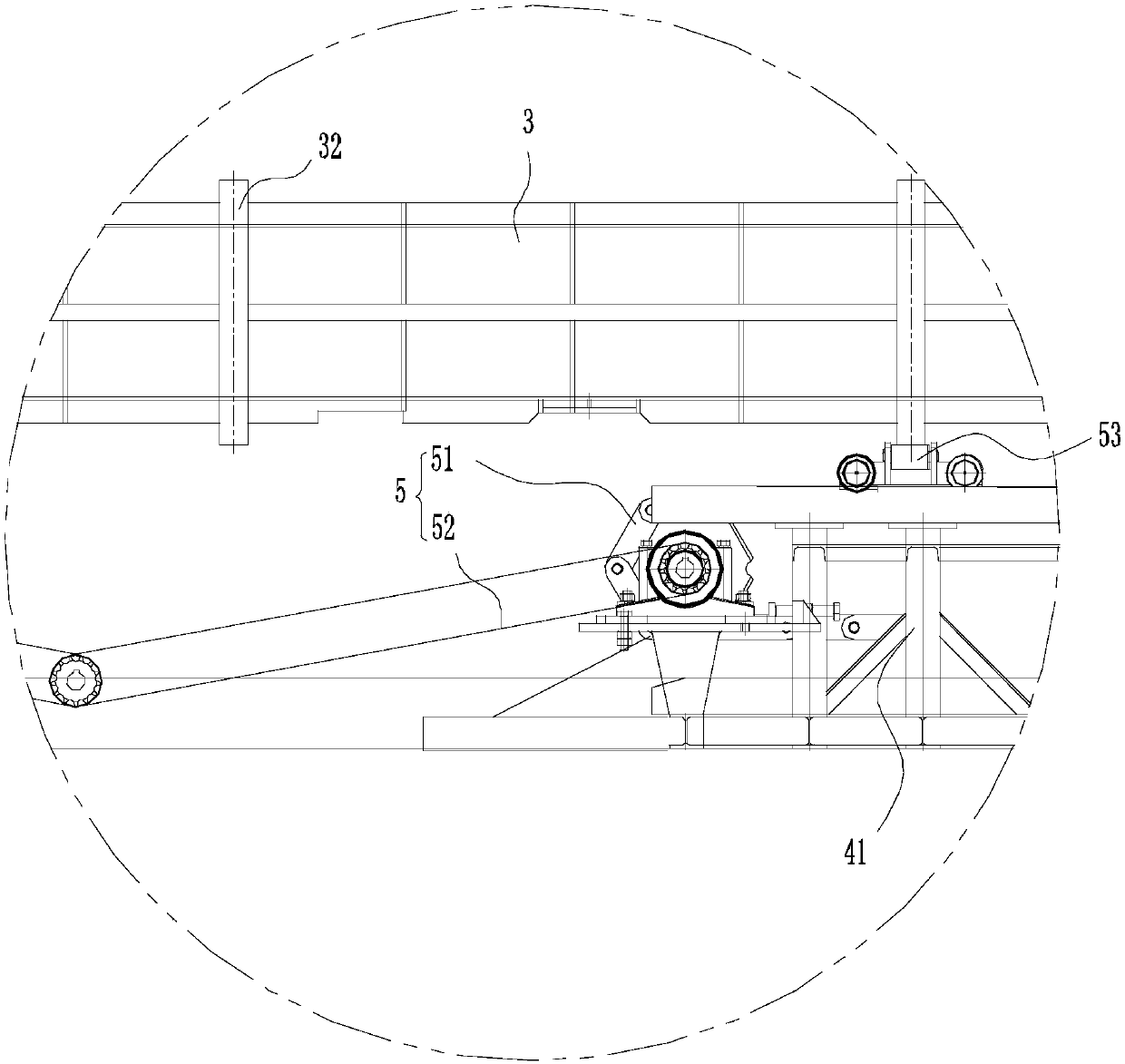

[0045] Such as figure 1 As shown, this embodiment discloses a pumping and distributing equipment for pipe piles. The pumping and distributing equipment for pipe piles includes: a pump 1 , a pumping pipe 2 , a pipe pile mold 3 and a support frame 4 . In order to facilitate the detailed description of the pipe pile pumping and distributing equipment, the direction of the pumping pipe 2 towards the pipe pile form 3 is firstly defined as the front direction. In this embodiment, the rear end of the pumping pipe 2 is connected to the pump 1 and the front end extends to the feed port 31 of the pipe pile form 3 .

[0046] Specifically, the pump machine 1 is equipped with a weighing scale and a control system not shown in the figure, wherein the control system is electrically connected to the weighing scale, and the control system is electrically connected to the power device of the pump machine 1. In this embodiment, it is called The weight scale is used to measure the weight of the ...

Embodiment 2

[0068] In this embodiment, the parts that are the same as in the first embodiment are given the same reference numerals, and the same text descriptions are omitted.

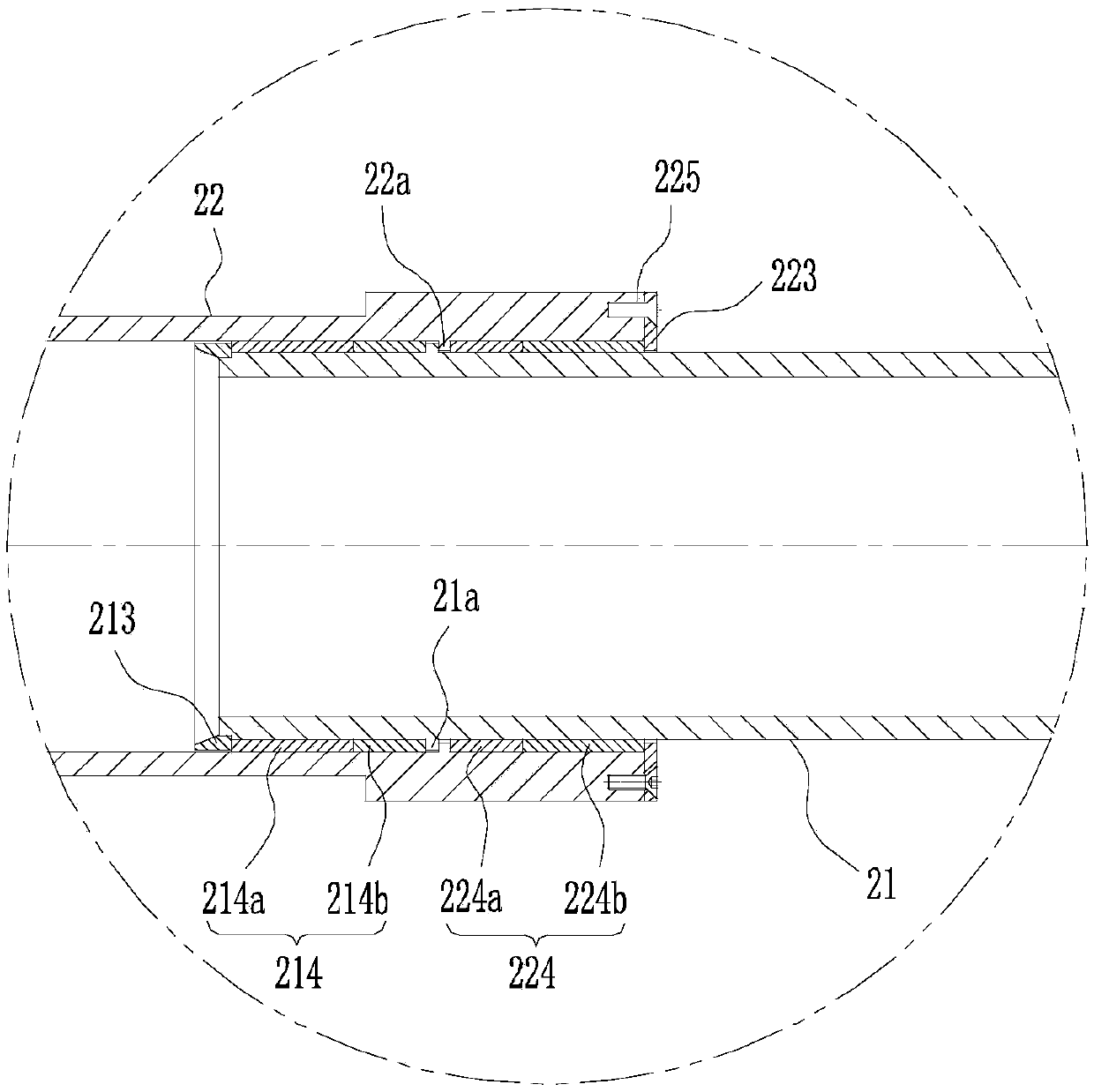

[0069] Compared with Embodiment 1, the telescopic pumping tube 2 provided in this embodiment also has such a structure: Figure 9 and 10 As shown, the first rigid pipe 21 includes a circular first pipe body 211 (ie, the inner pipe body) and a front sealing joint 212 in the shape of a rotary body, the rear end of the front sealing joint 212 and the first pipe body 211 (ie, the inner pipe body). The front end of the pipe body) is screwed or welded and fixed; in this embodiment, the outer annular stopper 21a is located on the front sealing joint 212, and the front sealing assembly 214 is axially sleeved on the front sealing joint 212; the front gland 213 and the first The front end of a pipe body 211 is welded and fixed, of course, for the convenience of maintenance, the front gland 213 and the front end of the fir...

Embodiment 3

[0073] In this embodiment, the parts that are the same as in the second embodiment are given the same reference numerals, and the same text descriptions are omitted.

[0074] Compared with Embodiment 2, the telescopic pumping tube 2 provided in this embodiment also has the following structure:

[0075] Such as Figure 13 As shown, in this embodiment, the pumping pipe 2 also includes a third rigid pipe 23, specifically, the diameter of the third rigid pipe 23 is larger than the diameter of the second rigid pipe 22 so that the third rigid pipe 23 is axially sleeved On the second rigid tube 22 , and the third rigid tube 23 can freely slide in the axial direction relative to the second rigid tube 22 to be fitted, so as to realize further expansion and contraction of the overall length of the pumping tube 2 .

[0076] In this embodiment, the first rigid tube 21 is the innermost rigid tube, the second rigid tube 22 is the outer rigid tube relative to the first rigid tube 21 ; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com