Automatic tray distribution and stacking system

A palletizing system and automatic distribution technology, applied in the field of palletizing systems, can solve complex and changeable problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

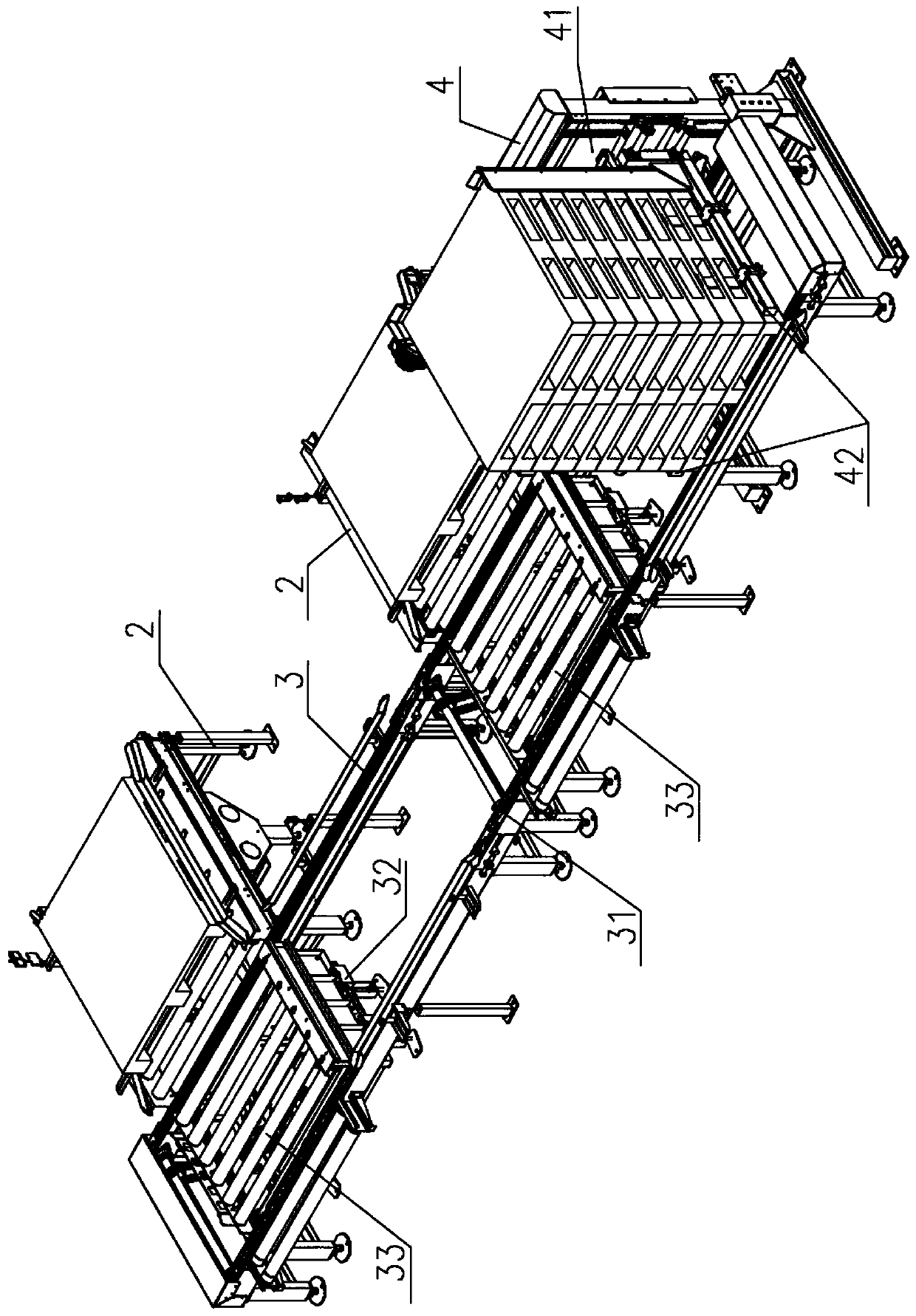

[0031] As an embodiment of the present invention, the rolling support component is a conveyor belt with idler roller sets.

[0032] As an embodiment of the present invention, the empty pallet conveying component is a transmission chain structure.

[0033] As an embodiment of the present invention, the empty tray conveying part is a driving roller structure.

[0034] The pallet automatic distribution and palletizing system is a digital control system, which can be seamlessly connected with the factory's digital bus to realize centralized digital management, and is not limited to the above-mentioned specific control methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com