Anti-leakage bag and preparation method and preparation equipment thereof

A leak-proof and equipment-based technology, applied in bags, sacks, and bag-making operations, can solve problems such as unstable quality, low production efficiency, and poor product consistency, saving labor, time, and cost, and improving production efficiency and quality stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

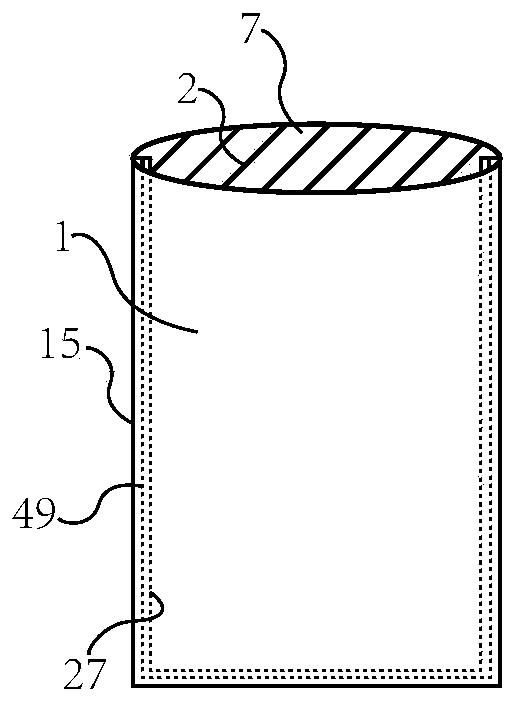

[0134] Figure 1 to Figure 3 shows a leak-proof bag with an opening 7 according to the present invention.

[0135] figure 1 Shown is the schematic diagram of this embodiment in general use state picture . It includes a fabric layer 1 and a sealing layer 2, both of which together constitute the bag body; the fabric layer 1 bears the gravity of the contents in the bag, and the sealing layer 2 ensures that the contents in the bag in liquid state or containing liquid will not leak.

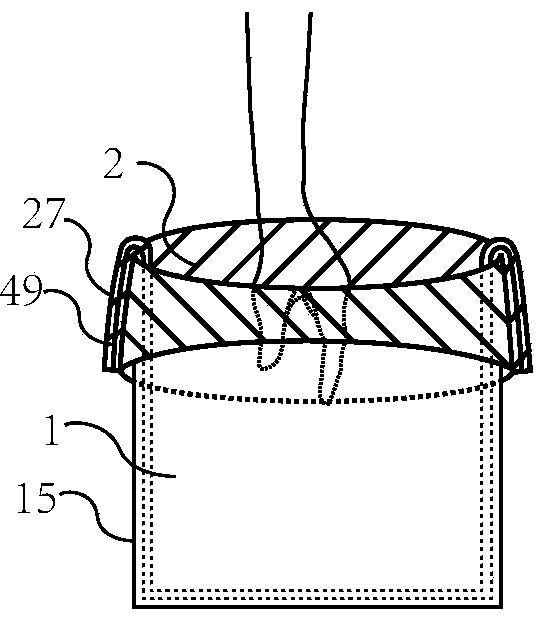

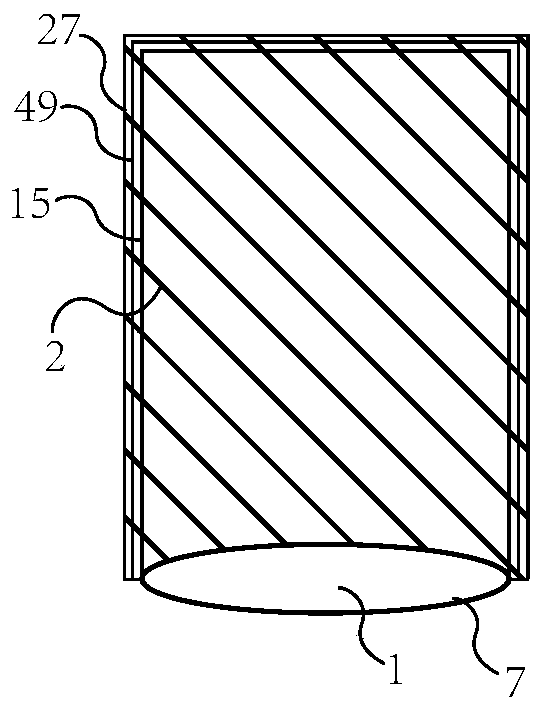

[0136] figure 2 Shown is the process of the user reaching into the bag body to turn the sealing layer 2 from the inside. image 3 Shown: all fabric layers 1 are turned inside the bag body, and all sealing layers 2 are turned outside the bag body. That is, it turns out that figure 1 The "fabric layer 1 on the outside, seal layer 2 on the inside" shown becomes as follows image 3 "Sealing layer 2 on the outside, fabric layer 1 on the inside" is shown.

[0137] For the convenience of understan...

Embodiment 2

[0140] Figure 4 to Figure 6 shows a leak-proof bag with a handle 6 and an opening 7 according to the present invention.

[0141] Its structure is the same as that disclosed in Embodiment 1, the only difference being that a handle 6 is added in this embodiment.

[0142] The handle 6 can be attached before or after the sealing layer 2 is pasted by methods including pre-sewing or final seaming, ultrasonic, glue bonding, hot stamping, high-frequency welding and the like. In order to reduce the possibility of the sewing machine needle piercing through the leak-proof bag, if sewing is used, it is preferably attached before the sealing layer 2 is attached.

Embodiment 3

[0144] Figure 7 to Figure Shown in 9 is a waterproof bag used in outdoor activities of the present invention (that is, a special form of leak-proof bag, except that the bag mainly does not prevent the content inside the bag from leaking out, but mainly prevents the outside world from leaking out. Rain or water seeps into the inside of the bag body to wet the contents when people carry out outdoor activities).

[0145] After the user puts the content in the bag, the user seals the opening 7 by gathering and tightening the folding strips 8 on both sides of the opening 7, and then bends the tightly rolled folding strips 8 to make the The male buckle 9 is inserted into the female buckle 10, so that the sealing structure will not be scattered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com