Exhaust valve assembly, compressor and refrigeration equipment

An exhaust valve and component technology, applied in mechanical equipment, pump components, variable capacity pump components, etc., can solve the problems affecting the energy efficiency of compressors, complex structure, etc., and achieve the effect of reducing compression loss and improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

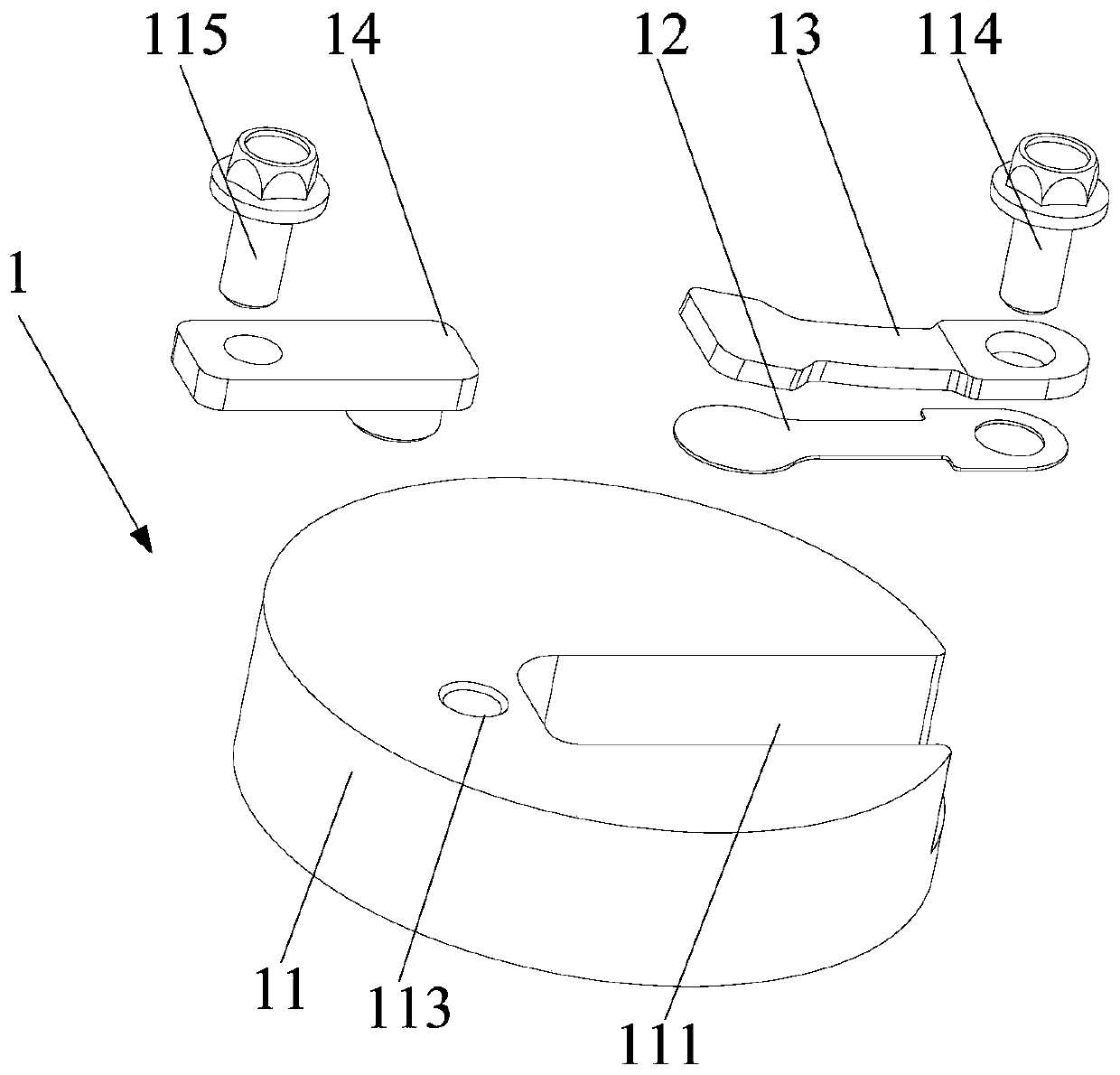

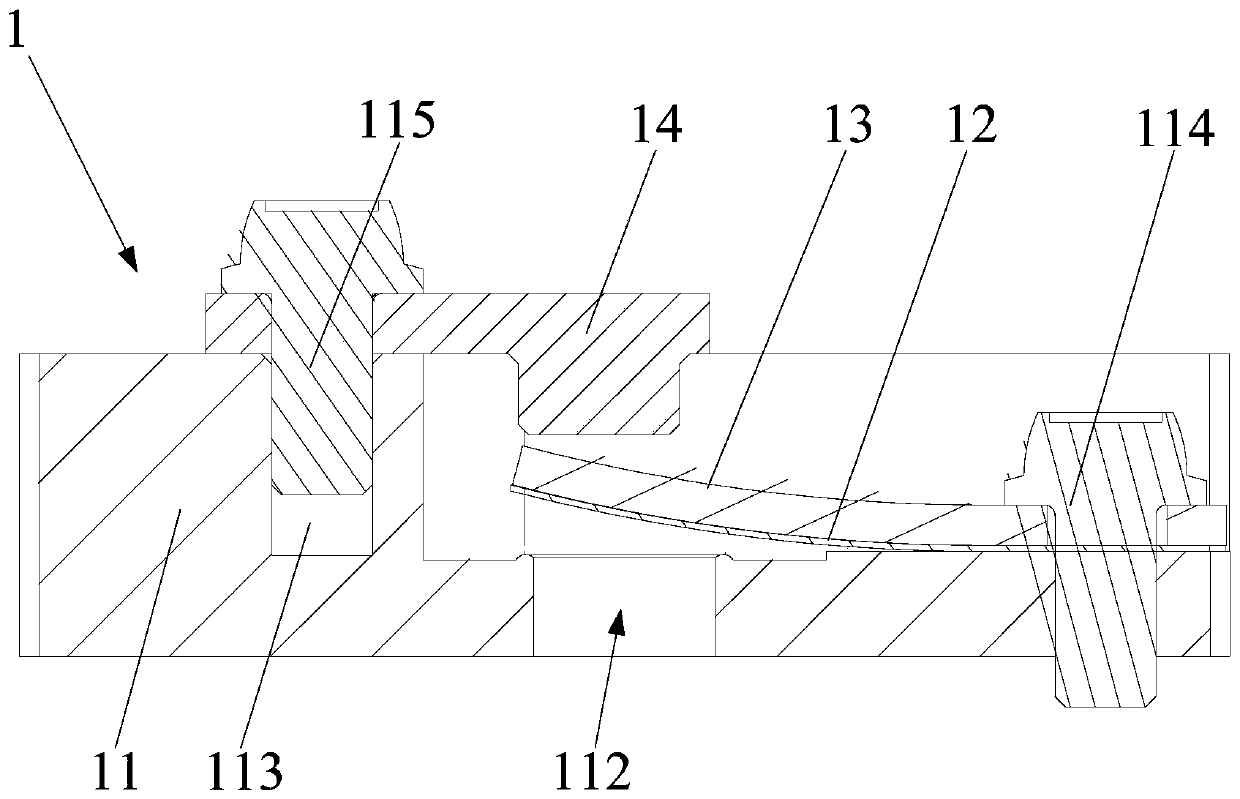

[0040] Such as Figure 1 to Figure 10 As shown, this embodiment provides an exhaust valve assembly 1, the exhaust valve assembly 1 includes a valve seat 11, a valve plate 12 and an auxiliary opening and closing mechanism, the valve seat 11 is provided with an exhaust port 112, The valve plate 12 has a free end and a fixed end, the fixed end is fixed on the valve seat 11, and the free end is covered on the exhaust port 112; the auxiliary opening and closing mechanism is used for An auxiliary force is applied to the free end, and the direction of the auxiliary force is directed from the exhaust port 112 to the free end.

[0041] Such as figure 1 and Figure 5 As shown, the auxiliary opening and closing mechanism provided in this embodiment includes a valve seat 11, a valve plate 12 and an auxiliary opening and closing mechanism. The auxiliary force at the free end, when the compression chamber needs to be changed, the auxiliary force exerted by the auxiliary opening and closi...

Embodiment 2

[0045] Such as Figure 1 to Figure 3As shown, the exhaust valve assembly 1 provided in this embodiment includes a valve seat 11, a valve plate 12 and an auxiliary opening and closing mechanism, the valve seat 11 is provided with an exhaust port 112, and the valve plate 12 has a free end and a fixed end, the fixed end is fixed on the valve seat 11 , and the free end is covered on the exhaust port 112 . The auxiliary opening and closing mechanism includes an electromagnetic device 14, and the electromagnetic device 14 is arranged corresponding to the free end to provide a magnetic attraction force to the free end, and overcome the elastic force of the valve plate 12 through the magnetic attraction force, but does not move the valve The free end of the sheet 12 adsorbs to open the exhaust port 112. At this time, the compression chamber does not need to overcome the elastic force of the valve sheet 12 during exhausting, which can reduce the pressure in the compression chamber duri...

Embodiment 3

[0058] Such as Figure 4 to Figure 9 As shown, this embodiment provides an exhaust valve assembly 1, the exhaust valve assembly 1 includes a valve seat 11, a valve plate 12 and an auxiliary opening and closing mechanism; the auxiliary opening and closing mechanism includes a driving member and a limiting member 16. The limiting member 16 includes a connected first rod portion 161 and a second rod portion 162, the cross-sectional size of the first rod portion 161 is larger than the cross-sectional size of the second rod portion 162; the valve seat 11 is provided with a limiting hole 116, the driving member is connected with one end of the first rod part 161, and the other end of the first rod part 161 is connected with the second rod part 162, and the second rod part The other end of 162 is inserted into the limiting hole 116, and the driving member is used to drive the limiting member 16 to move along the limiting hole 116 on the lower side of the valve plate 12; the second ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com