Anti-floating pile structure for soft soil foundation and construction method of anti-floating pile structure during wet season

A technology of soft soil foundation and construction method, which is applied in the direction of foundation structure engineering, sheet pile wall, protection device, etc., can solve problems such as damage effects, and achieve the effect of improving strength, guaranteeing structural strength, and ensuring the effect of bottom expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

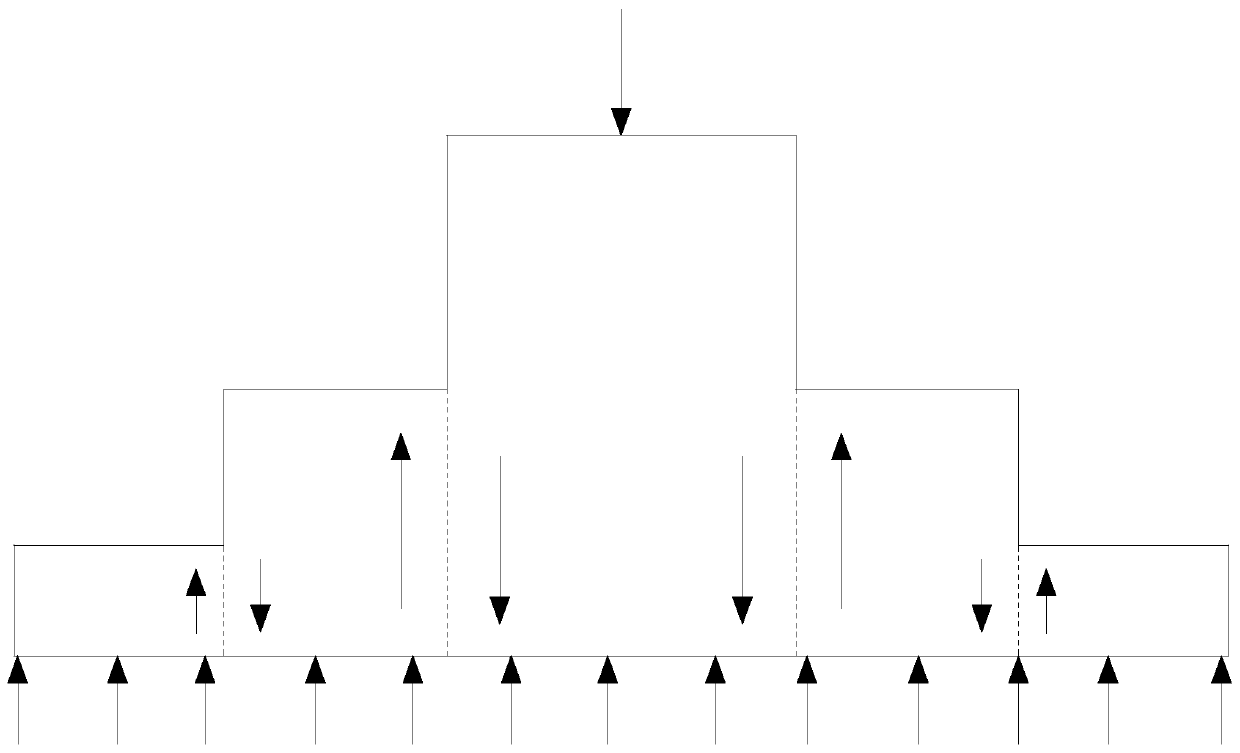

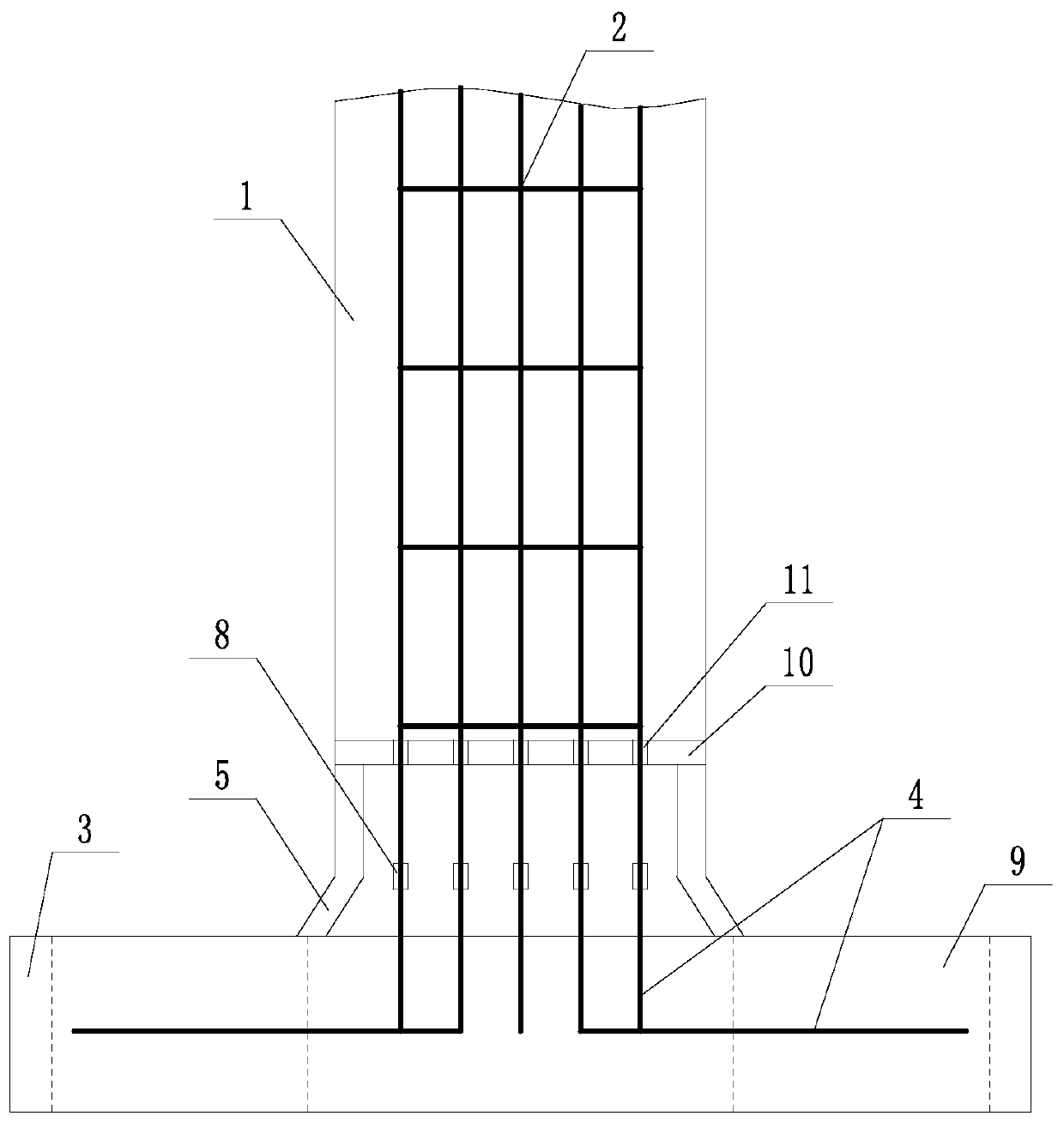

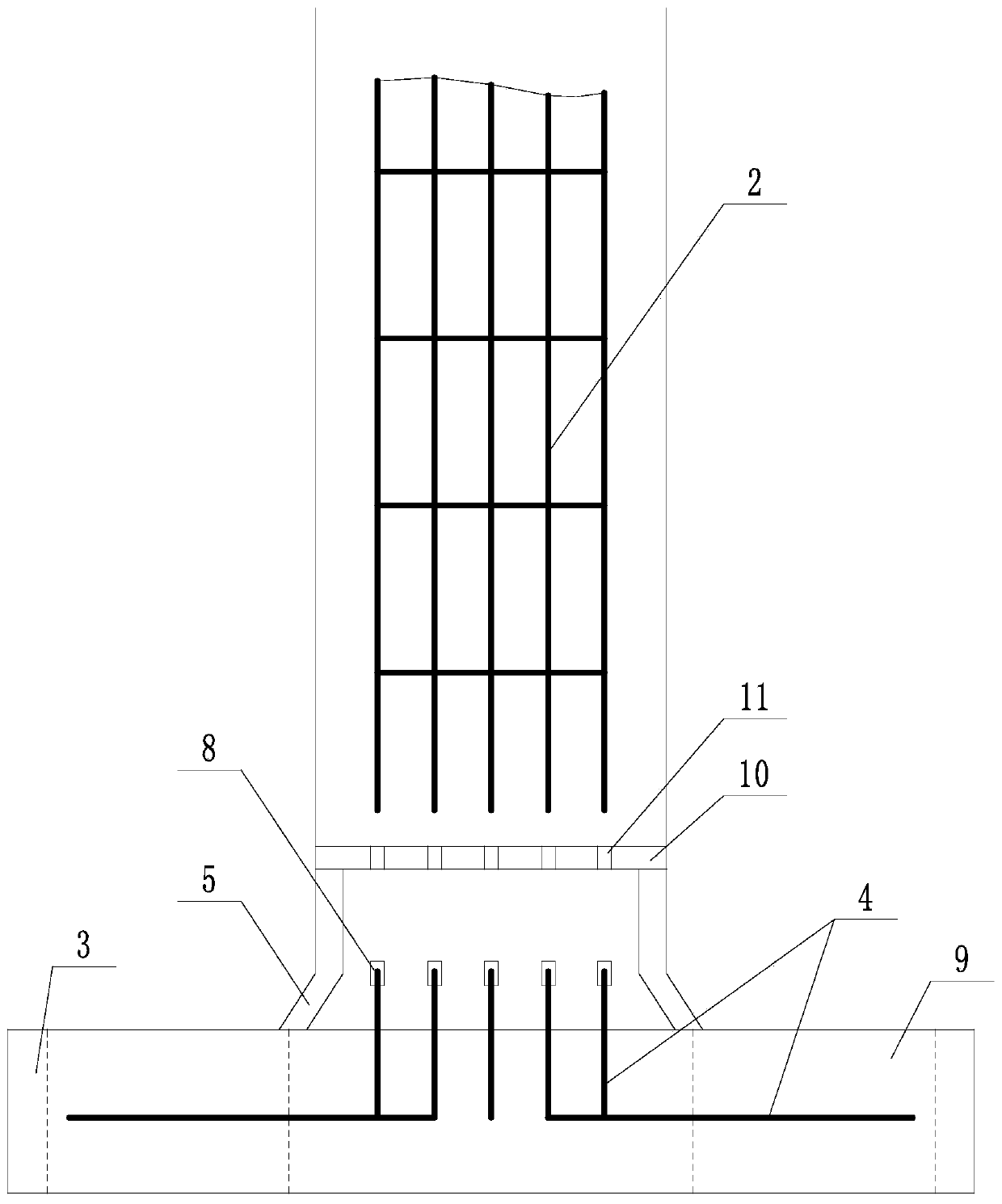

[0038] like Figure 2 to Figure 5 The shown anti-floating pile structure used in soft soil foundations includes a pile body 1 and a reinforcement cage 2 located inside the pile body 1. It is characterized in that it also includes a cap 3, and the upper surface of the cap 3 is provided with an annular The sleeve 5 and the cap 3 are provided with a number of preset ribs 4, the preset ribs 4 protrude from the upper surface of the cap 3 inside the sleeve 5, and the protruding preset ribs 4 are connected with the main ribs at the bottom of the reinforcement cage 2 One by one is facing; the top of the preset rib 4 is provided with a socket 6, and the bottom end of the main reinforcement on the steel cage 2 is provided with an insertion part 7 that matches the socket 6, and each insertion part 7 is inserted into the corresponding In the socket 6; the connection between the insertion part 7 and the socket 6 is also provided with a protective cover 8; a number of through holes 9 are pr...

Embodiment 2

[0044] like Figure 2 to Figure 5 In the shown anti-floating pile structure used in soft ground, on the basis of Example 1, the cap 3 and the sleeve 5 are all prefabricated concrete structures. It also includes a limiting plate 10 fixed on the top of the sleeve 5, a number of circularly distributed perforations 11 are arranged on the limiting plate 10, and several perforations 11 are directly opposite to the main reinforcements at the bottom of the reinforcement cage 2, and the main reinforcements at the bottom of the reinforcement cage 2 are respectively from Several perforations 11 pass through. The perforations 11 are directly opposite to the protective sleeves 8 one by one. The protective cover 8 includes a diameter-expanding part 801 distributed up and down, and a mounting part 802. The mounting part 802 is screwed to the top of the pre-set rib 4. The inner diameter of the diameter-expanding part 801 is larger than the outer diameter of the main reinforcement on the rein...

Embodiment 3

[0046] As the construction method of the anti-floating pile structure in the high water period in any of the above-mentioned embodiments, it may further comprise the steps:

[0047] (a) Excavate the foundation pit, the size of the foundation pit must be able to accommodate the cap 3;

[0048] (b) lift cap 3 and place it at the bottom of the foundation pit;

[0049] (c) lifting the reinforcement cage 2 vertically, so that the insertion part 7 on the main reinforcement at the bottom end of the reinforcement cage 2 is all inserted into the socket 6 at the top of the corresponding preset reinforcement 4;

[0050] (d) Formwork is set outside the reinforcement cage 2, and the foundation pit on the outside of the formwork is backfilled;

[0051] (e) Pour concrete into the formwork, take out the formwork after the pouring is completed, and wait for Ning.

[0052] A more preferred embodiment is that it also includes a limiting plate 10 fixed on the top of the sleeve 5 , so that each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com