Wood micro-drill resistance material cleaning sample detection fixing device

A technology of micro-drilling resistance and fixing devices, which is applied in the direction of measuring devices, mechanical devices, workpiece clamping devices, etc., can solve problems such as equipment damage, manual lifting labor intensity, and data acquisition errors, etc., to reduce labor intensity, The effect of reducing the risk of damage and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

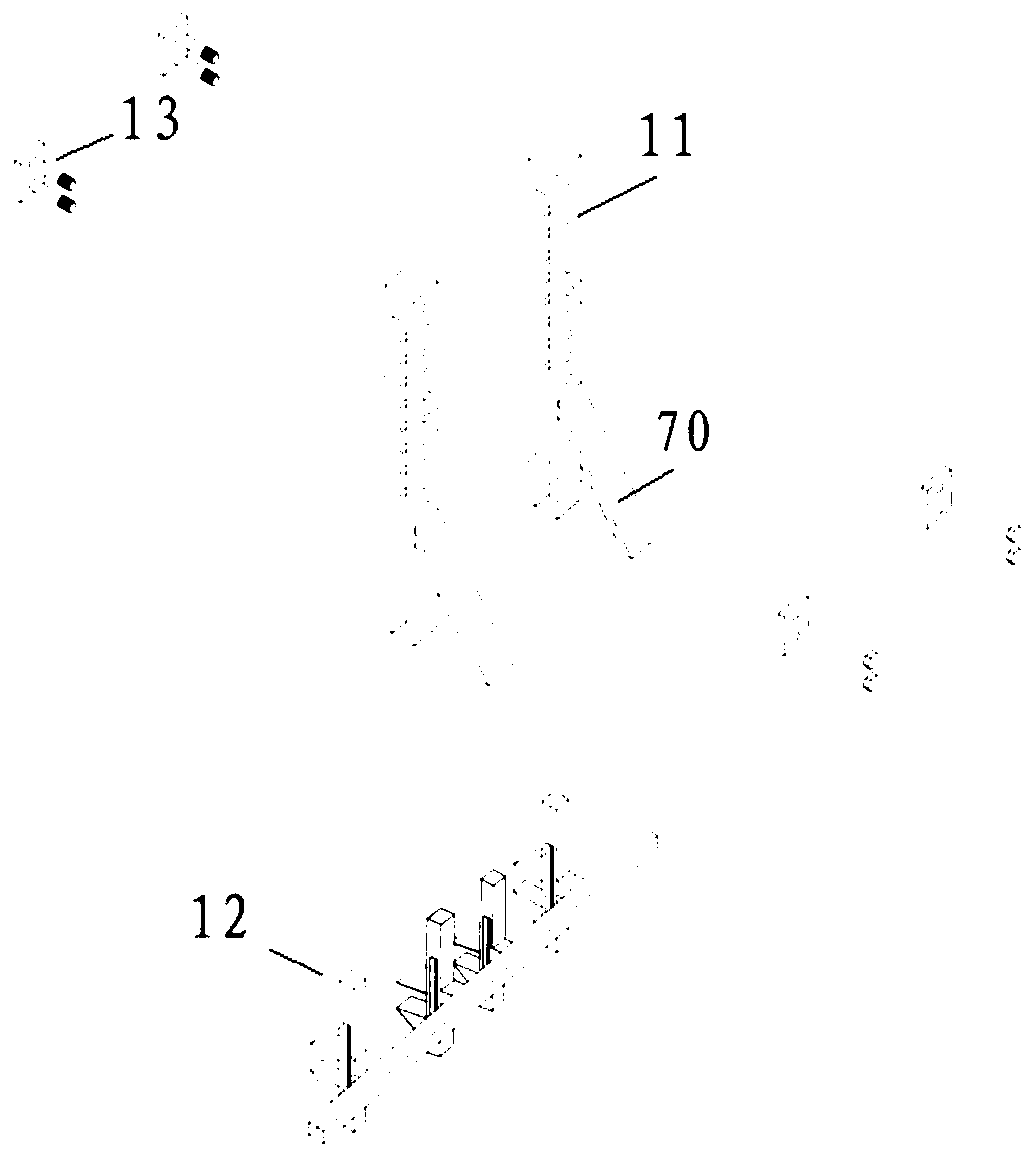

[0046] According to the size requirements of the test piece in the national standard "Test Method for Compressive Resistance of Wood Cross Grain" (GB / T 1939-2009), the size of the clear material sample 50 is 60mm×20mm×20mm. see Figure 15 , during the detection process, use the two spring clamps 122 in the middle of the horizontal bracket 12 of the sample fixing unit 10 to clamp the clear material sample 50 horizontally, and fix the testing equipment 60 on the testing equipment fixing unit by tightening the limit bolt 22 In the plate-type U-shaped slot 21 of 20, as a specific embodiment of the present invention, the detection device 60 uses a micro-drill resistance meter. By adjusting the position in the bolt hole on the longitudinal support 11 that the position adjustment bolt 13 is screwed into, the clamping height of the clear material sample 50 on the sample fixing unit 10 is adjusted, so that the clear material sample 50 and the micro-drill resistance meter 60 are located...

Embodiment 2

[0048] According to the national standard "Determination of Timber Flexural Modulus of Elasticity" (GB / T 1936.2-2009) on the size of the specimen, the size of the clear material sample 50 is 300mm×20mm×20mm. see Figure 16, the difference from Example 1 is that in this example, during the detection process, four spring clamps 122 of the transverse support 12 of the sample fixing unit 10 are used to clamp the clear material sample 50 horizontally, and by tightening the limit bolt 22 The detection device 60 is fixed in the plate-type U-shaped slot 21 of the detection device fixing unit 20. As a specific embodiment of the present invention, the detection device 60 uses a micro-drill resistance meter. By adjusting the position in the bolt hole on the longitudinal support 11 that the position adjustment bolt 13 is screwed into, the clamping height of the clear material sample 50 on the sample fixing unit 10 is adjusted, so that the clear material sample 50 and the micro-drill resis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com