Double-cam universal rotary table

A universal turntable and double-cam technology, applied in the field of universal turntable, can solve the problems that the turntable cannot be independently rotated and controlled, the motion structure has a dead point, and affects the use of linkage control, etc., so as to facilitate daily use, avoid accidental collision accidents, extend The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

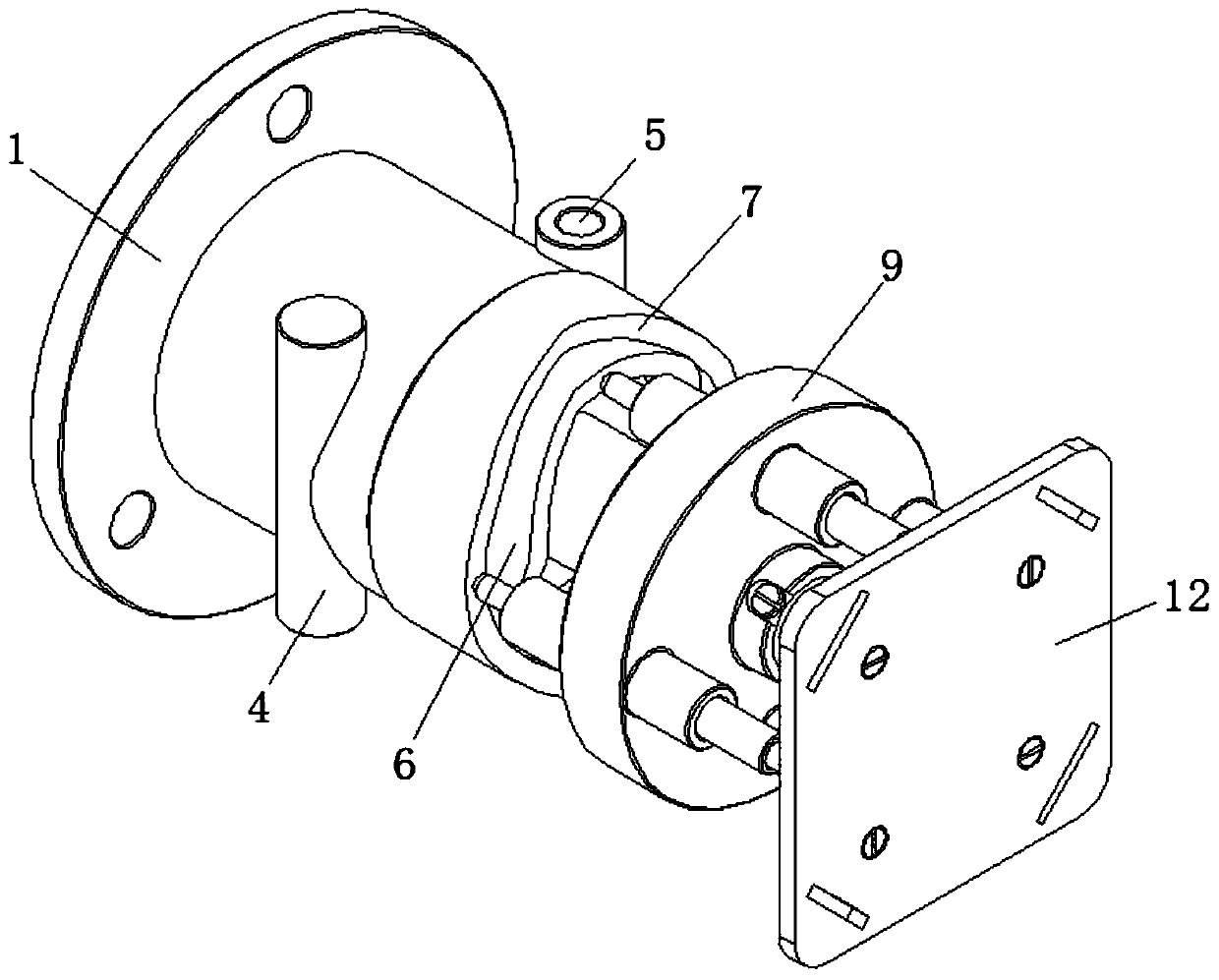

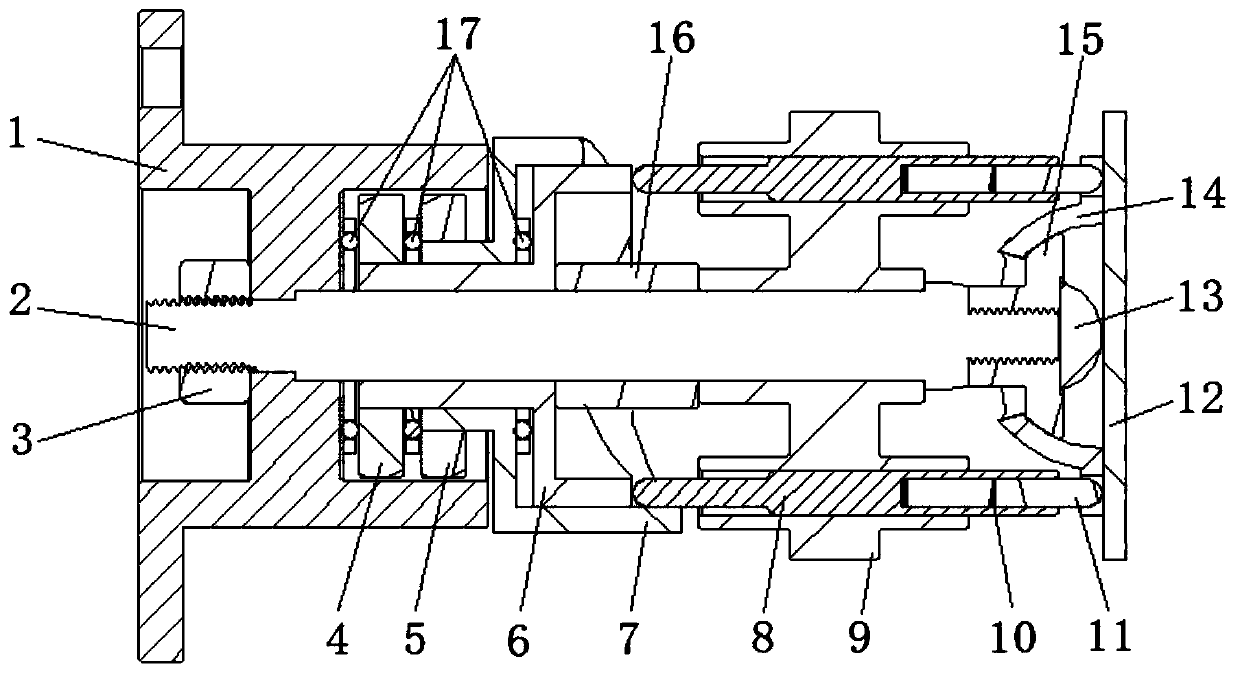

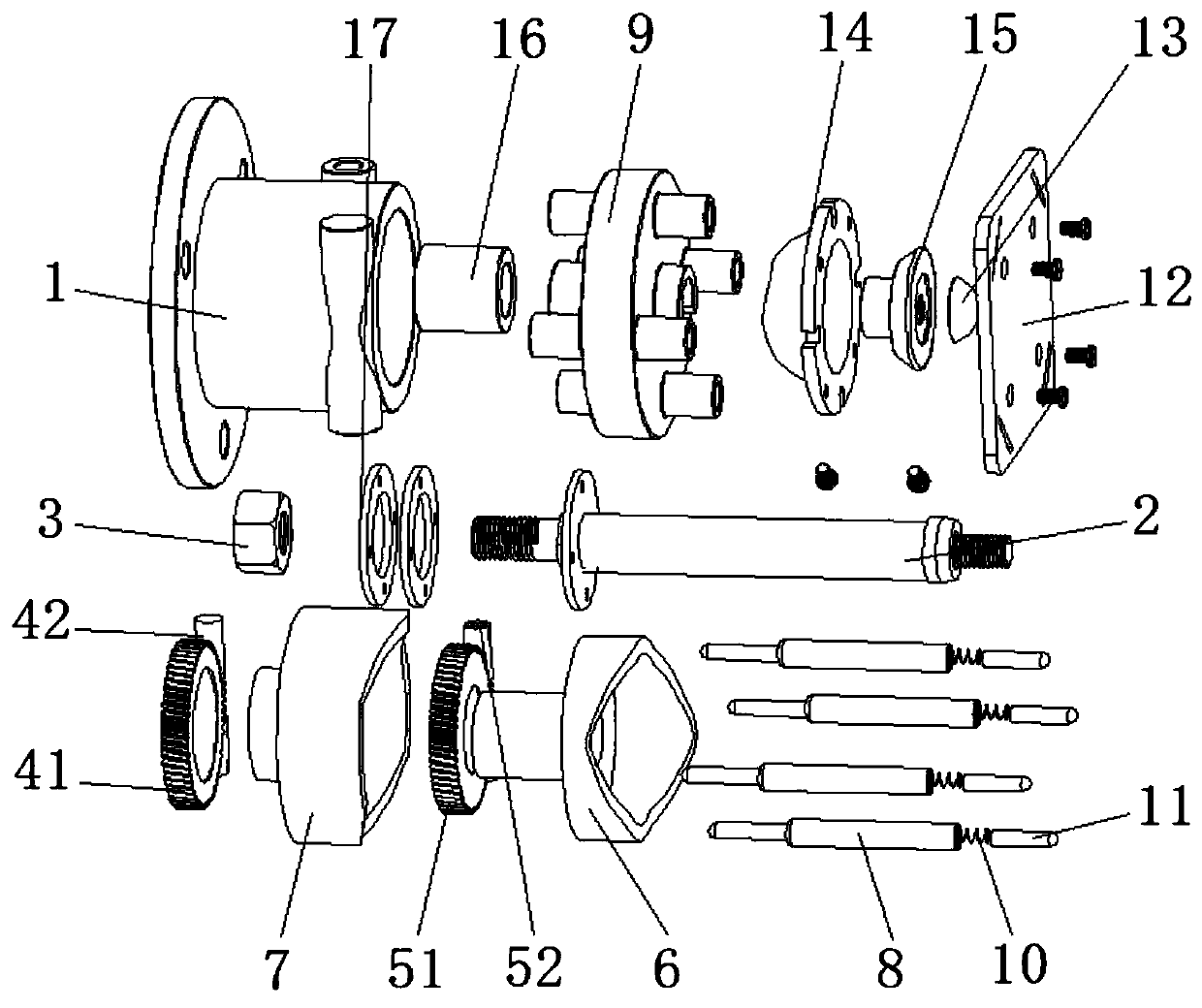

[0029] Such as Figure 1-3 As shown, the present invention provides a double-cam universal turntable, including a base 1, a mandrel 2, a push rod frame 9 and a workbench 12, and one end of the mandrel 2 is fixedly connected to the base 1 through a nut 3, so that A push rod frame 9 is sleeved in the middle of the mandrel 2, and a first cam 6 and a second cam 7 are sleeved on the outer side of the mandrel 2 between the base 1 and the push rod frame 9, and the first cam 6 Sleeved on the inner side of the second cam 7, and in order to avoid the relative sliding action of the push rod frame 9, the outer side of the mandrel 2 is sleeved with a support sleeve 16 between the first cam 6 and the push rod frame 9. The first cam 6 and the second cam 7 are equipped with a first turbine mechanism 4 and a second turbine mechanism 5 respectively on the inner side of the base 1, and the first turbine mechanism 4 includes a first turbine 41 and a first scroll 42, and The first worm wheel 41 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com