Universal blue pliers

An integrated, connecting arm technology, applied in the field of universal blue pliers, can solve the problems that the cutting part cannot be changed in multiple directions, the operating range is small, and a single direction, etc., to prevent back and forth shaking, easy to use, and stable in structure and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

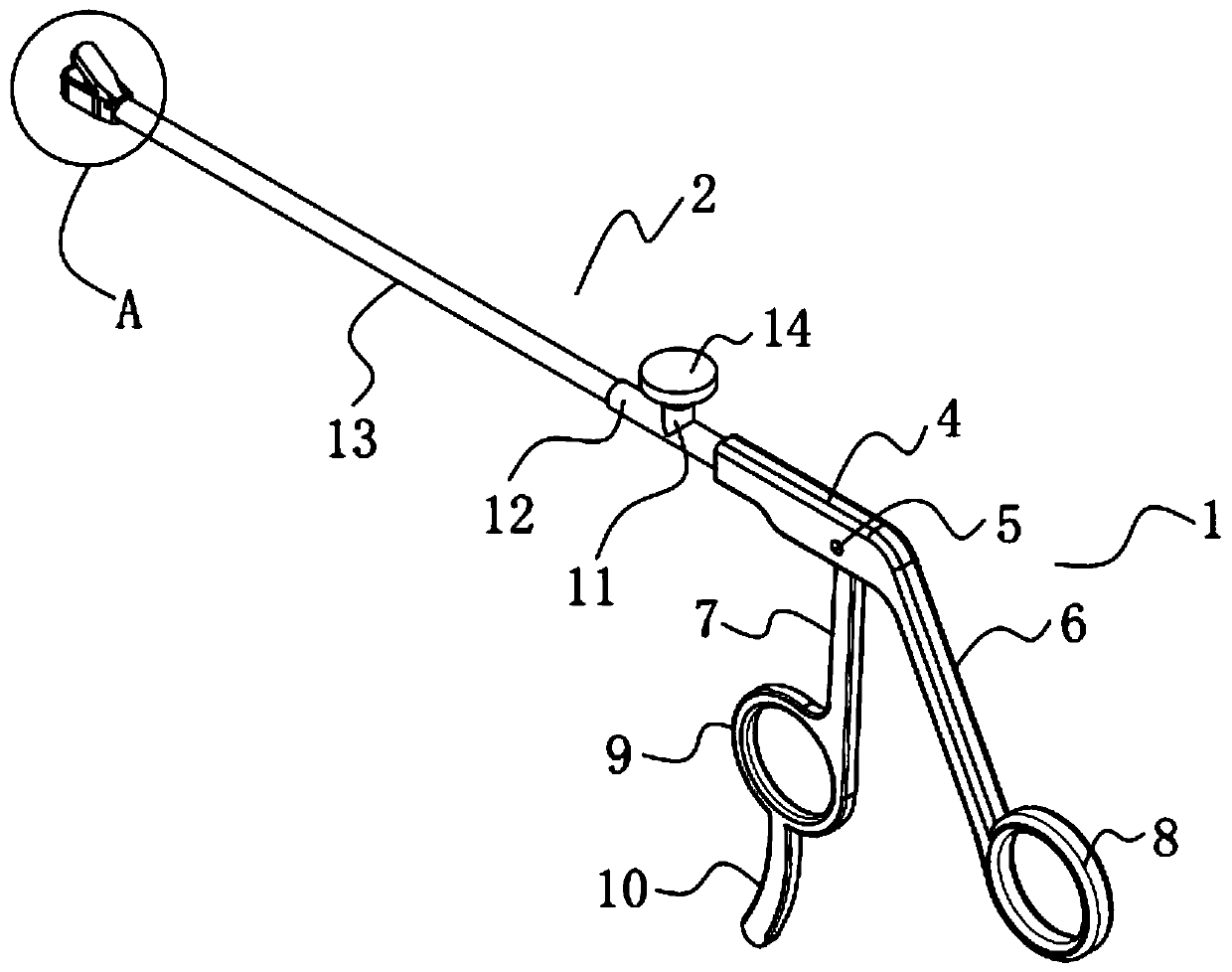

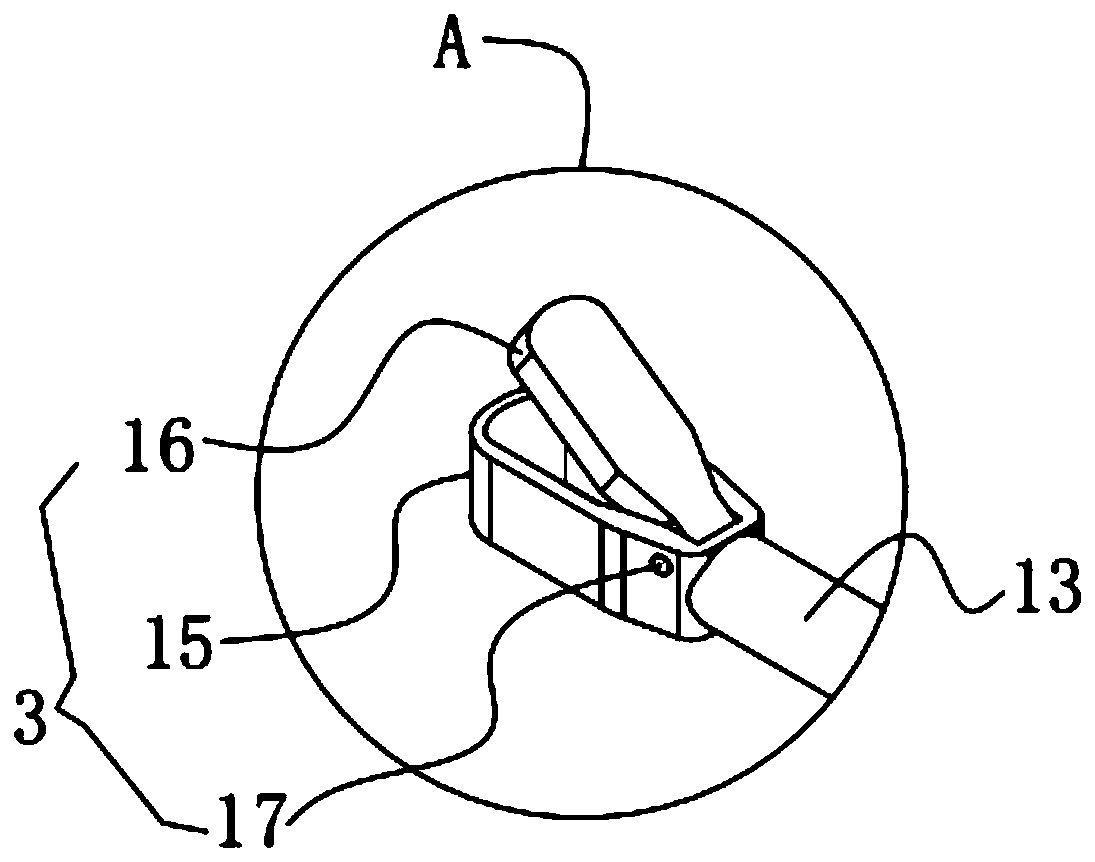

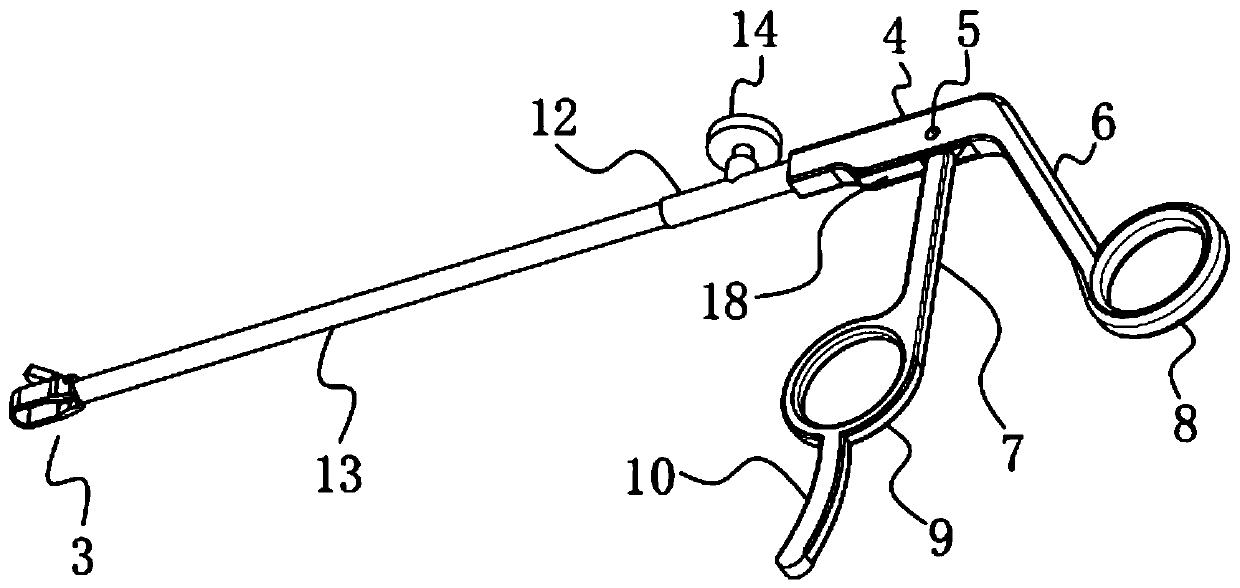

[0046] A kind of universal blue pliers, such as figure 1 and 3 As shown, it includes a hand-held operation part 1, a connection adjustment part 2 and a cutout part 3, and the cut-out part 3 is connected to the hand-held operation part 1 through the connection adjustment part 2;

[0047] like figure 1 and 3 As shown in -5, the handheld operation part 1 includes a mounting frame 4, a first connecting arm 6, a first grip ring 8, a connecting seat 20, a second connecting arm 7, a second grip ring 9 and a connecting piece 21. The bottom of the mounting frame 4 is provided with a mounting groove 18, the first connecting arm 6 is integrally arranged at one end of the mounting frame 4, and the first grip ring 8 is integrally arranged at the end of the first connecting arm 6 away from the One end of the mounting bracket 4, the connecting seat 20 is hinged inside the installation groove 18 through the first pin shaft 5, the second connecting arm 7 is fixedly installed on the bottom o...

Embodiment 2

[0064] The difference from Example 1 is that a protective layer is also provided on the outer surface of the connecting pipe 13, and the protective layer is prepared by the following method:

[0065] Take the following raw materials and weigh them by weight: 18 parts of epoxy resin powder, 10 parts of calcium carbonate powder, 13 parts of copper oxide powder, 15 parts of nano-silver powder, 10 parts of titanium dioxide powder, 3 parts of alcohol ester twelve, 2 parts of triethanolamine, 1 part of high carbon alcohol fatty acid ester complex and 30 parts of water;

[0066] S1. Add the weighed calcium carbonate powder, copper oxide powder, nano-silver powder, titanium dioxide powder, alcohol ester dodecane, triethanolamine, higher alcohol fatty acid ester complex and water into the beaker;

[0067] S2. Place the beaker in which the raw materials are added in step 2 on the shelf above the alcohol lamp, and heat the beaker for 10 minutes with the alcohol lamp, during which time the ...

Embodiment 3

[0073] The difference with embodiment 2 is the preparation of protective layer, and its specific preparation method is as follows:

[0074] Take the following raw materials and weigh them by weight: 22 parts of epoxy resin powder, 13 parts of calcium carbonate powder, 16 parts of copper oxide powder, 18 parts of nano-silver powder, 12 parts of titanium dioxide powder, 4 parts of alcohol ester twelve, 3 parts of triethanolamine, 2 parts of high carbon alcohol fatty acid ester complex and 35 parts of water;

[0075] S1. Add the weighed calcium carbonate powder, copper oxide powder, nano-silver powder, titanium dioxide powder, alcohol ester dodecane, triethanolamine, higher alcohol fatty acid ester complex and water into the beaker;

[0076] S2. Place the beaker in which the raw materials were added in step 2 on the shelf above the alcohol lamp, and heat the beaker for 13 minutes with the alcohol lamp. During this period, use a glass rod to continuously stir in the same direction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com