Double-station automatic blanking riveting equipment

A double-station, blanking technology, applied in the field of riveting parts, can solve the problems of uneven riveting quality, poor product consistency, complex equipment structure, etc., and achieve the effects of saving working time, high working efficiency and saving operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

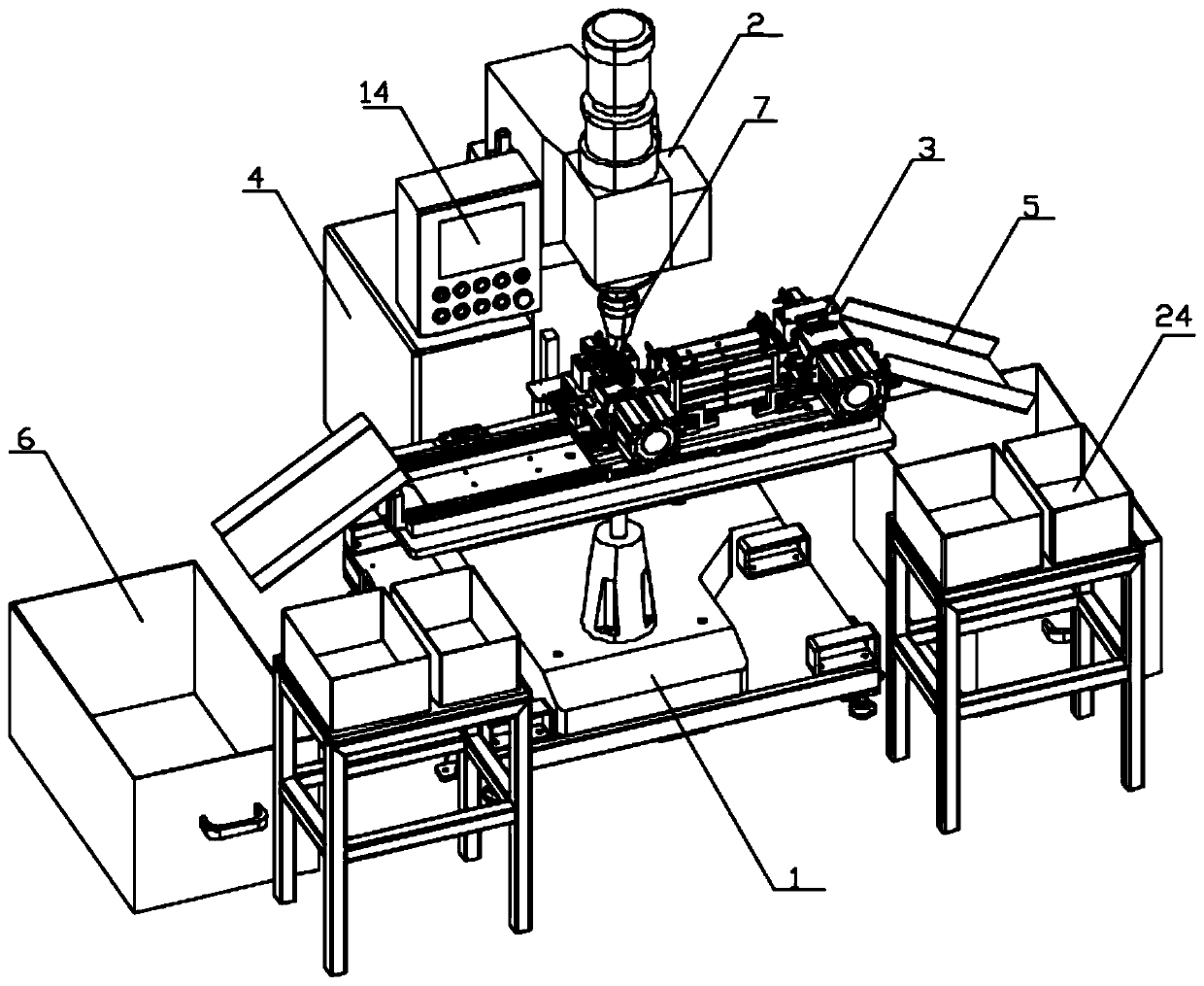

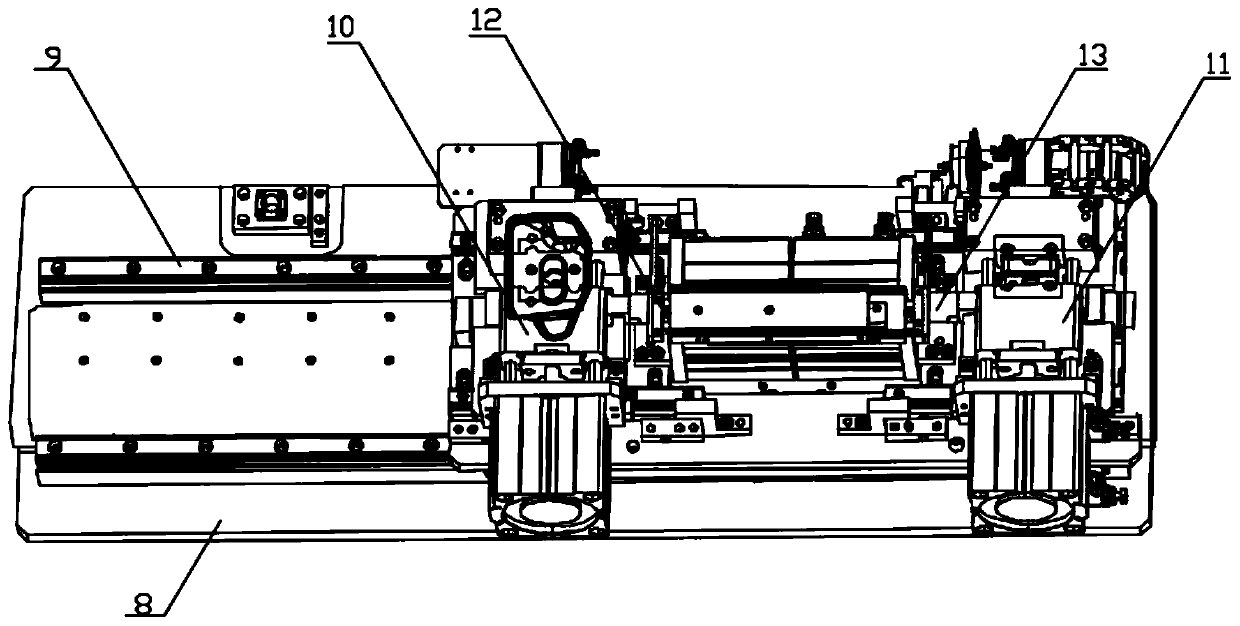

[0040] like Figure 1-2 As shown, a dual-station automatic blanking riveting equipment includes a machine base 1, a spin riveting machine 2, a riveting jig 3, and a control cabinet 4; the riveting jig 3 is fixed on the machine base 1, and the riveting jig 3 has There are blanking chutes 5 at both ends of the blanking chute; a finished material box 6 is provided below the blanking chute 5; the riveting machine 2 is fixed on the base 1, and the riveting of the riveting machine 2 The head 7 corresponds to the top of the riveting fixture 3; the riveting fixture 3 includes a fixture base 8, a station switching slide table 9, a left workpiece positioning and pressing mechanism 10, a right workpiece positioning and pressing mechanism 11, a left station drop Material mechanism 12, right station blanking mechanism 13; the fixture base 8 is fixedly installed on the machine base 1, and the two station switching slides 9 are arranged in parallel on the fixture base 8, and the left workpie...

Embodiment 2

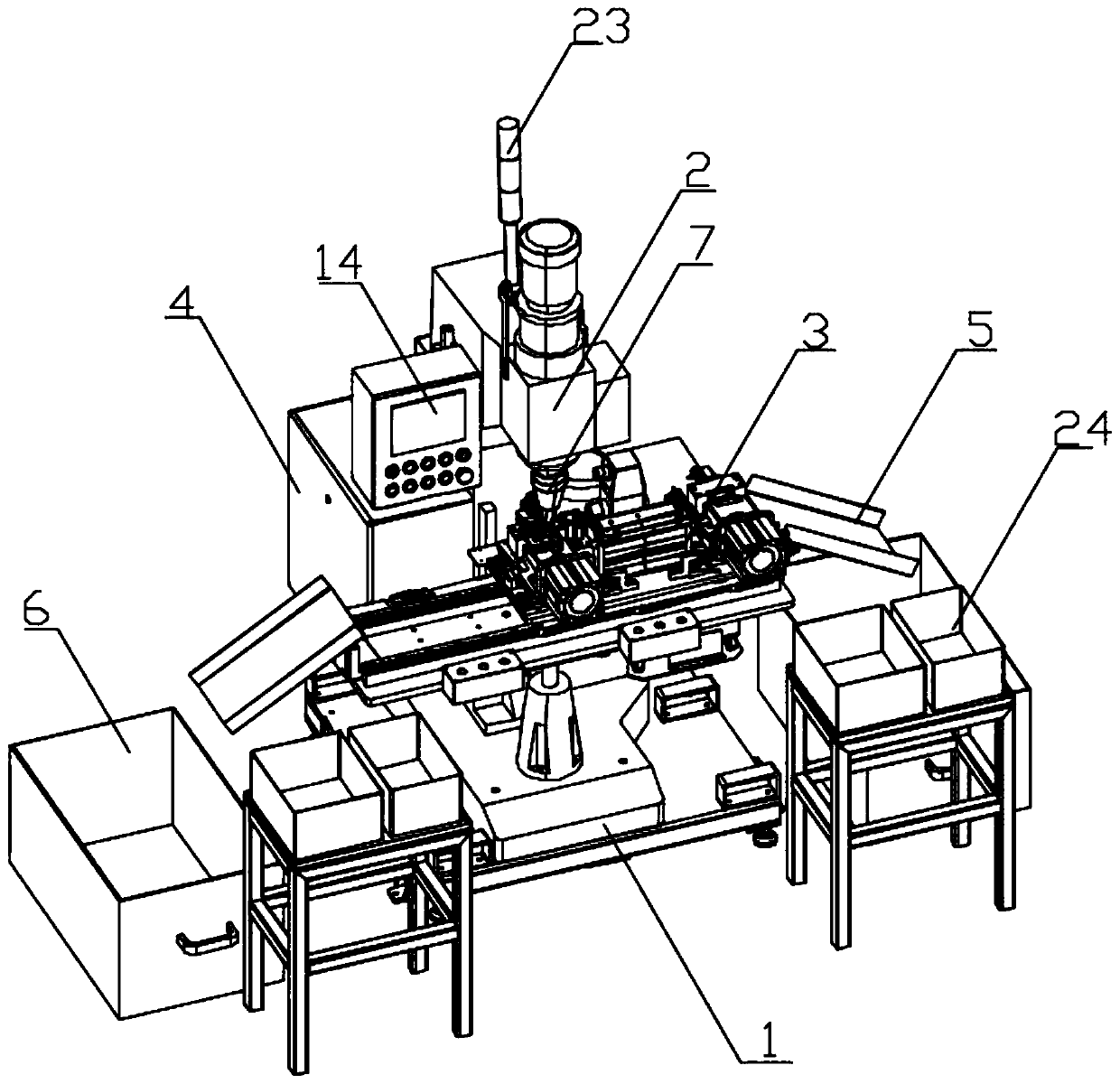

[0044] like Figure 3-6 As shown, this embodiment is basically the same as Embodiment 1, the difference is:

[0045] The left workpiece positioning and pressing mechanism 10 includes a first pressing cylinder 15 and a first workpiece positioning and pressing assembly, and the output end of the first pressing cylinder 15 is fixedly connected with the first workpiece positioning and pressing assembly; A pressing cylinder 15 is electrically connected with the PLC controller; the right workpiece positioning and pressing mechanism 11 includes a second pressing cylinder 16 and a second workpiece positioning and pressing assembly, and the output end of the second pressing cylinder 16 It is fixedly connected with the second workpiece positioning and pressing assembly; the second pressing cylinder 16 is electrically connected with the PLC controller. The first workpiece positioning and pressing assembly includes a positioning base plate 26, a pushing plate 25, and a pressing block 27;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com