A processing method for steel cage of long helical bored cast-in-place pile

A technology of long helical drilling and processing methods, applied in the direction of wire processing, wire mesh, household appliances, etc., can solve problems such as lack of specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

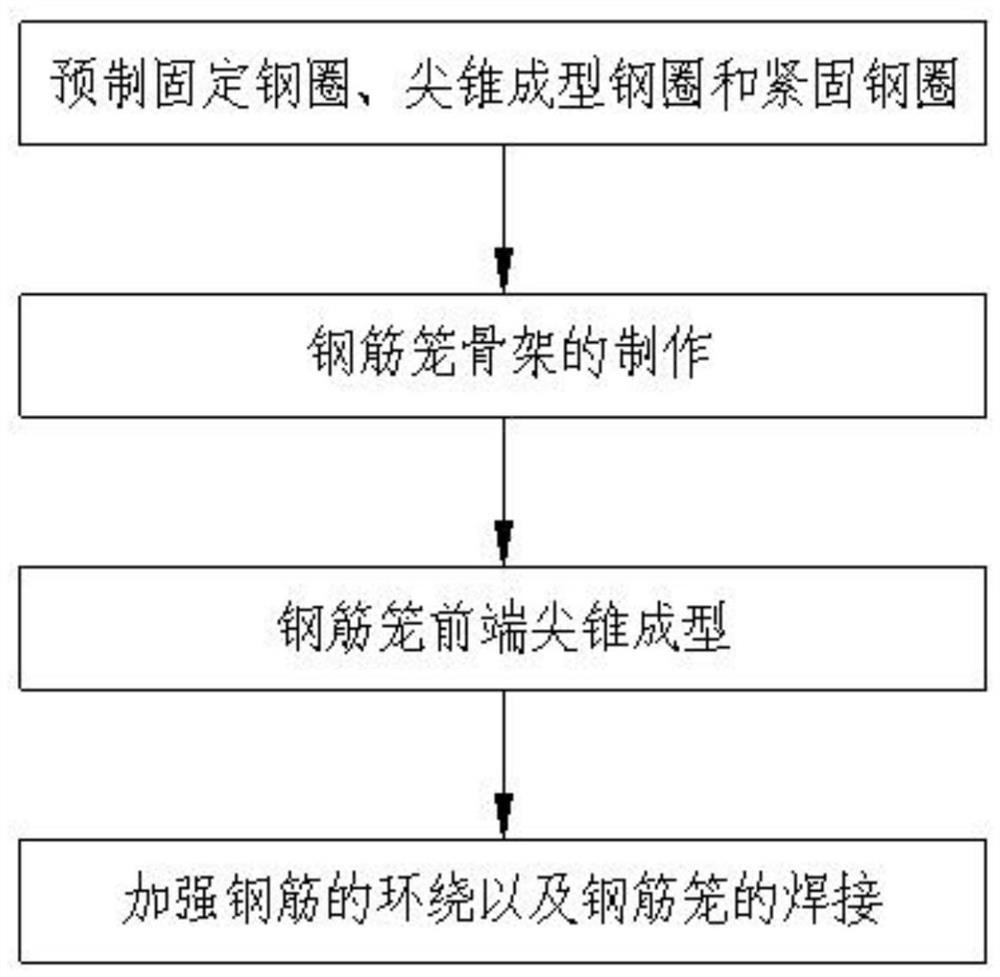

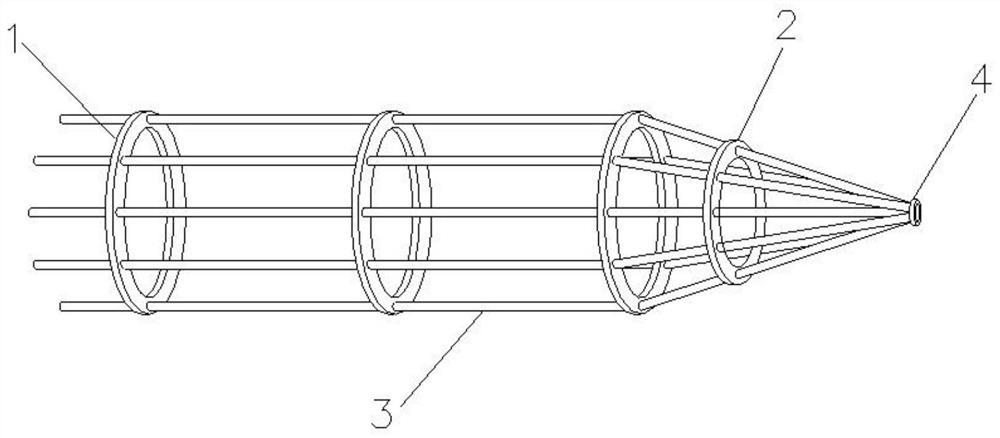

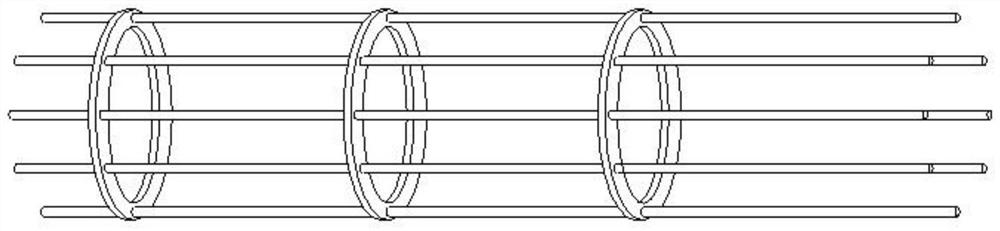

[0057] Such as Figure 1-6 shown

[0058] A method for processing a long helical bored cast-in-situ pile reinforcement cage, comprising the following steps:

[0059] Step 1. Prefabricated fixed steel ring 1, tapered steel ring 2 and fastening steel ring 4

[0060] Make a number of fixed steel rings 1 with the same specifications and uniform through holes around the edge; make at least three tapered steel rings 2 with through holes whose diameters are successively reduced relative to the fixed steel rings 1; make a fastening steel ring Circle 4;

[0061] Evenly distributed through holes are opened in the circumferential direction of the outer edge of the fixed steel ring 1, the diameter of the through holes is larger than the outer diameter of the main reinforcement, and the through holes are spaced at 30° or 45°.

[0062] The axial center position of a fixed steel ring 1 at the front end is welded with a steel pipe coincident with the axial center through the supporting spo...

Embodiment 2

[0078] Application of a method for processing steel cages of long auger bored cast-in-place piles in cast-in-place piles with steel cages inserted after long auger drilled press-filled concrete.

[0079] According to the above operation method, according to the length of the long auger bored cast-in-place pile reinforcement cage, select a suitable fixed steel ring 4 and fastening steel ring 4 for production, thereby obtaining a long auger drilled cast-in-place pile reinforcement cage for long auger drilled piles. Application in cast-in-situ pile engineering with reinforced cage inserted after pouring concrete.

[0080] The processing method of the steel cage of the long helical drilled cast-in-place pile of the present invention, through prefabricating the fixed steel ring, the sharp cone forming steel ring and the fastening steel ring; the making of the steel cage skeleton; the sharp cone forming at the front end of the steel cage; Welding of reinforcement cages; Efficient an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com