Drill rod grabbing component, drill rod loading and unloading arm, and loading and unloading machine for coal mine

A technology for grabbing parts and loading and unloading machines, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of high labor intensity of workers, reduce labor intensity and risk factor, improve drill pipe loading and unloading efficiency, and drill pipe capacity. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1: Drill pipe loading and unloading

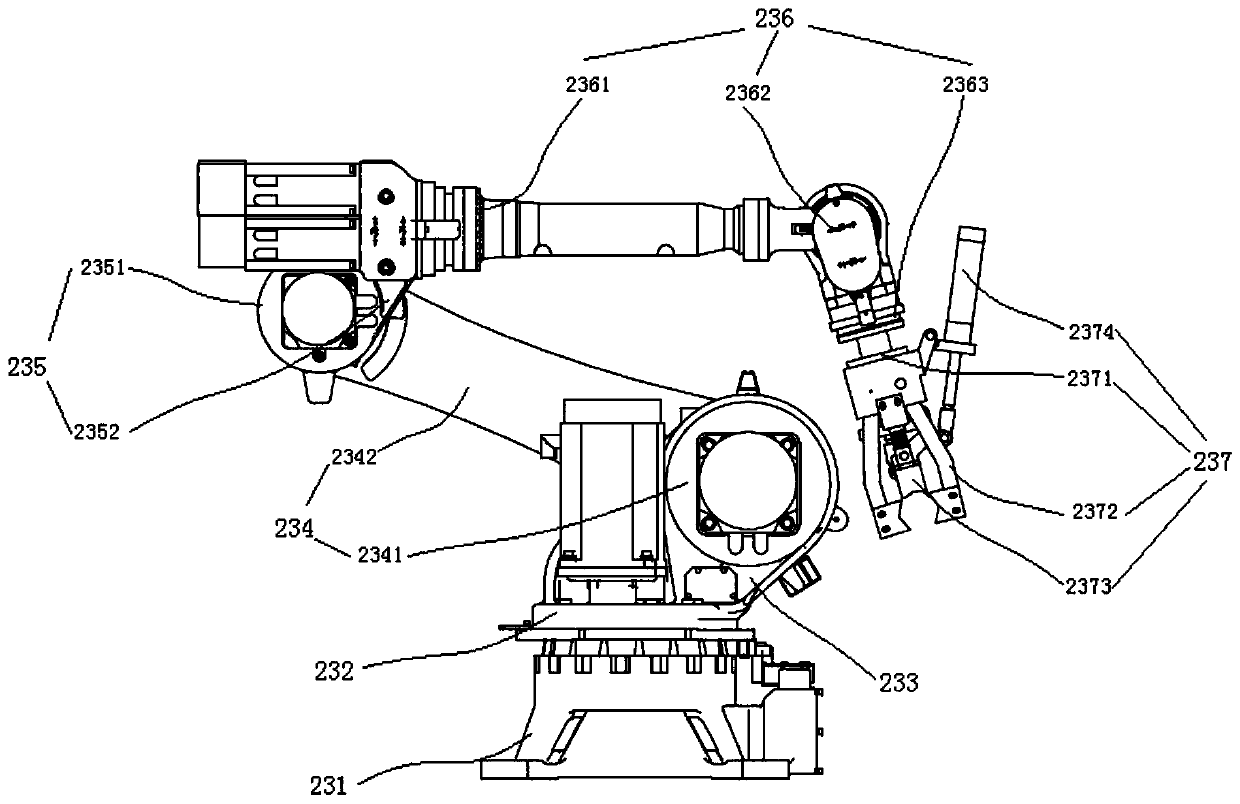

[0061] The construction method of the drill pipe loader and unloader for coal mines of the present invention includes a rod adding process and a rod unloading process. The rod adding process includes four steps: drill rod position identification, drill rod grabbing, drill rod transport and drill rod clamping. The unloading process includes three steps: drill pipe grabbing, drill pipe return transportation and drill pipe stacking.

[0062] The specific steps of the rod addition process are as follows:

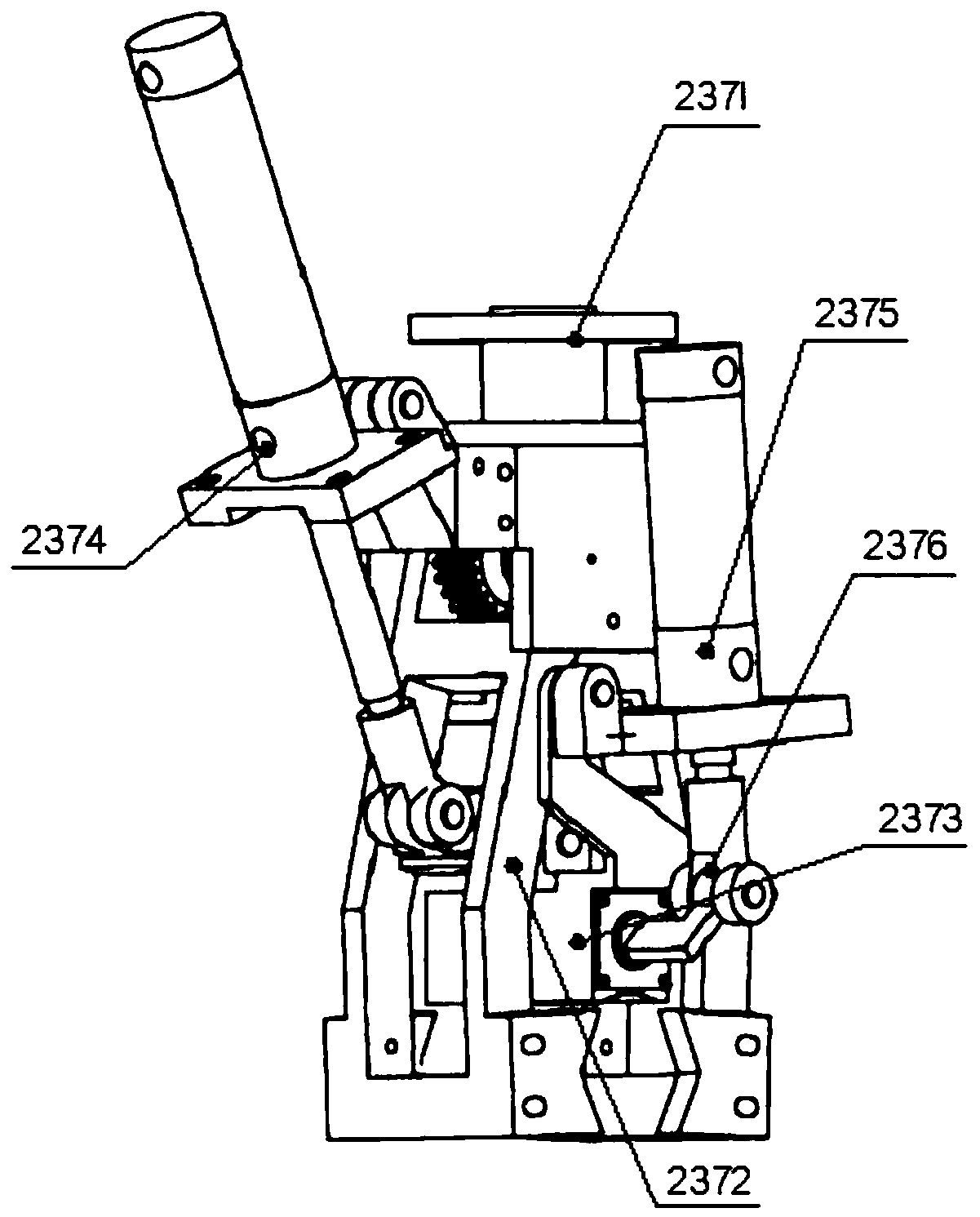

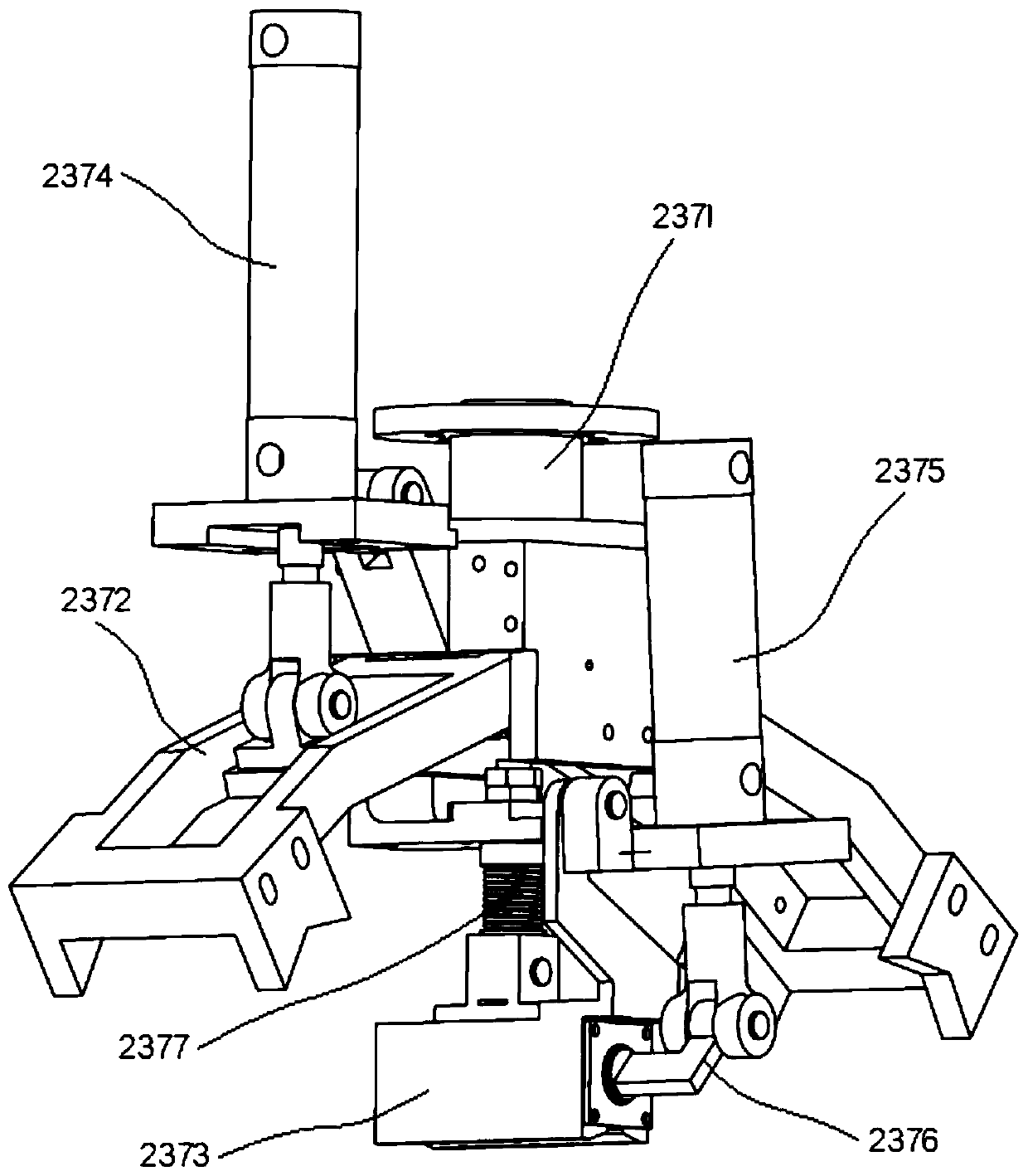

[0063] Step 1 (Recognition of drill pipe position): After the drill pipe loading and unloading arm is powered on, adjust the magnetic gripper 2373 to the calibration position through the wireless remote control. After the adjustment is completed, the drill rod loading and unloading arm 23 is calibrated according to the program. position, move the magnetic gripper 2373 to the first rod grab position to grab the drill rod. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com