Soft body finger capable of dual-direction bending and manufacturing method thereof

A software and finger technology, applied in the direction of manipulators, manufacturing tools, chucks, etc., can solve problems such as single execution mode, small controllable range, complex structure, etc., and achieve the effect of wide application range, good bending effect, and good interactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

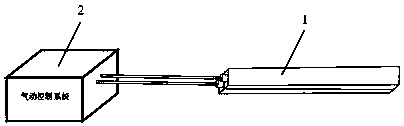

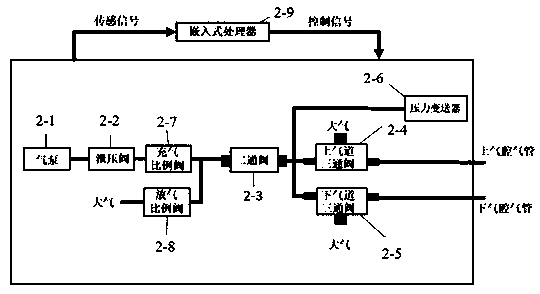

[0058] Such as figure 1 As shown, a soft finger that can bend in both directions can be realized. The soft finger 1 is connected with the pneumatic control system 2 through the upper air cavity trachea 1-4 and the lower air cavity trachea 1-5. The soft finger 1 is bent and deformed after being inflated. The pneumatic control system 2 can receive the user's instruction, output gas according to the instruction, make the soft finger 1 bend and deform to the desired state, and realize the change of the inflatable air cavity of the soft finger 1 by adjusting the air path, so as to realize two-way bending and satisfy the grip Requirements for grip or assistive rehabilitation training.

Embodiment 2

[0059] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows:

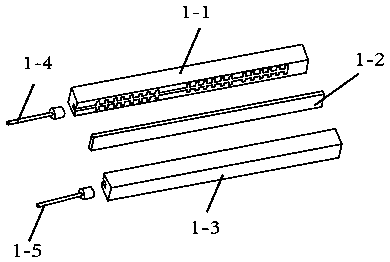

[0060] Such as image 3 As shown, the soft finger 1 is composed of an upper soft body envelope layer 1-1, a strain-limiting layer 1-2 and a lower soft body envelope layer 1-3, and an upper air cavity trachea 1-4 connected to the upper air cavity of the soft finger and connected The lower air cavity of the soft finger lower air cavity consists of trachea 1-5. In this embodiment, the upper soft body envelope layer 1-1 and the lower soft body envelope layer 1-3 are soft body structures made of Dragonskin 20 silica gel material. Bonded into a whole finger.

[0061] Such as Figure 4 As shown, the upper soft body enveloping layer 1-1 adopts a design in which cavities and soft body structures are distributed in folds, and the cavities communicate with each other through air passages. The upper surface of the soft envelope layer is connected together by silica ge...

Embodiment 3

[0064] The preparation method of the soft finger is used to prepare the above-mentioned soft finger, which is divided into the following three parts:

[0065] (1) For the soft envelope layer, the preparation steps are as follows:

[0066] Step 7-1: Use 3D modeling software to design the mold of the soft envelope layer, and use 3D printing to manufacture the mold (see Figure 5 );

[0067] Step 7-2: Pour a certain amount of uncured silica gel into the beaker in turn, stir until evenly poured into the mold (see Figure 7 Step 7-2), so that the silicone gel just fills the groove on the mold. If there is too much silicone liquid poured in, the excess silicone liquid should be removed with a needle stick;

[0068] Step 7-3: Put the mold filled with silicone liquid into the vacuum drying oven, connect the vacuum drying oven and the vacuum pump with the air pipe, turn on the vacuum air pump to evacuate for 10 minutes, then turn off the vacuum air pump and unplug the air pipe until ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Overall width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com