A new type of fast self-decoupling device

A fast and new technology, applied in the direction of transportation and packaging, load suspension components, etc., can solve the problems of spring fatigue failure and high safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

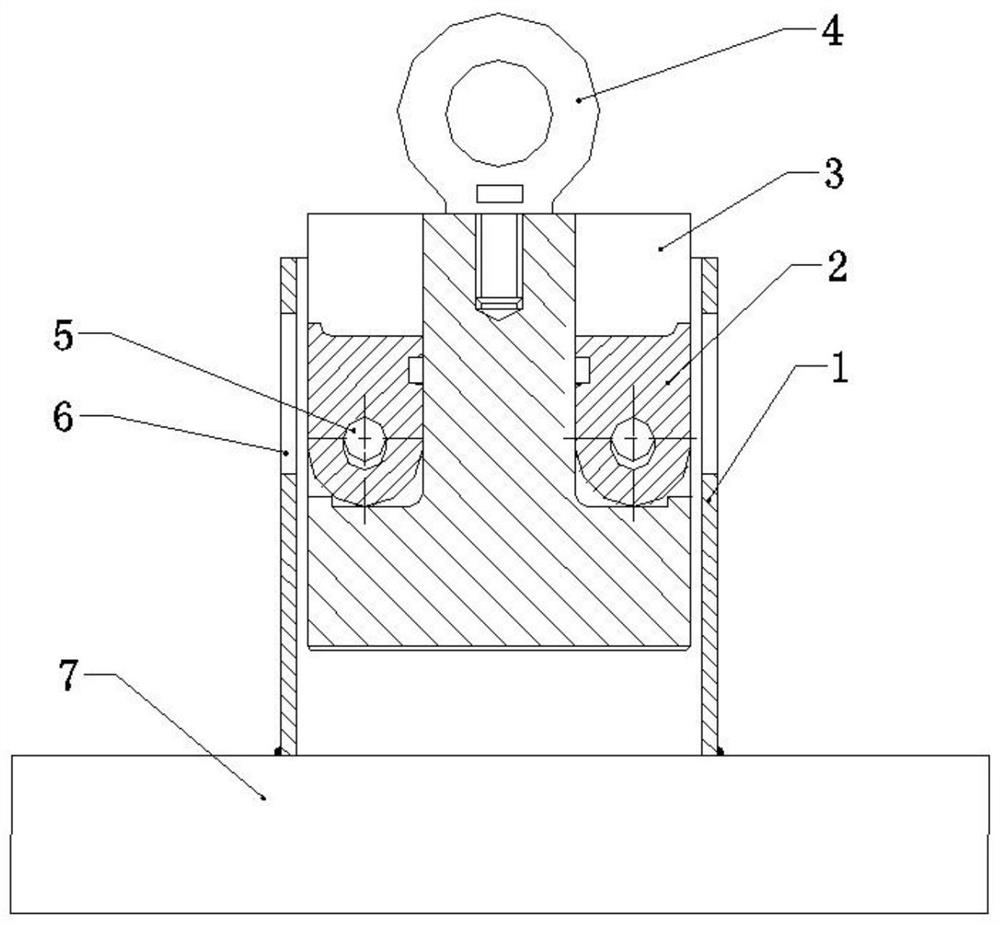

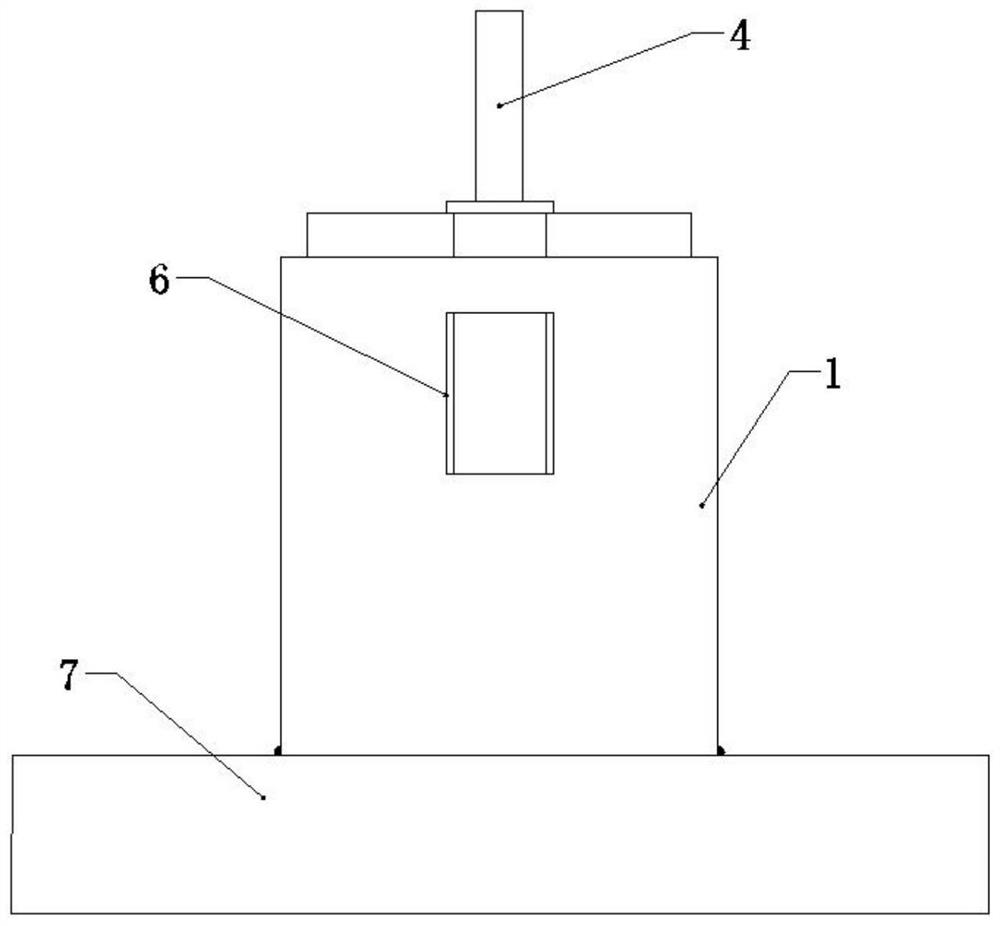

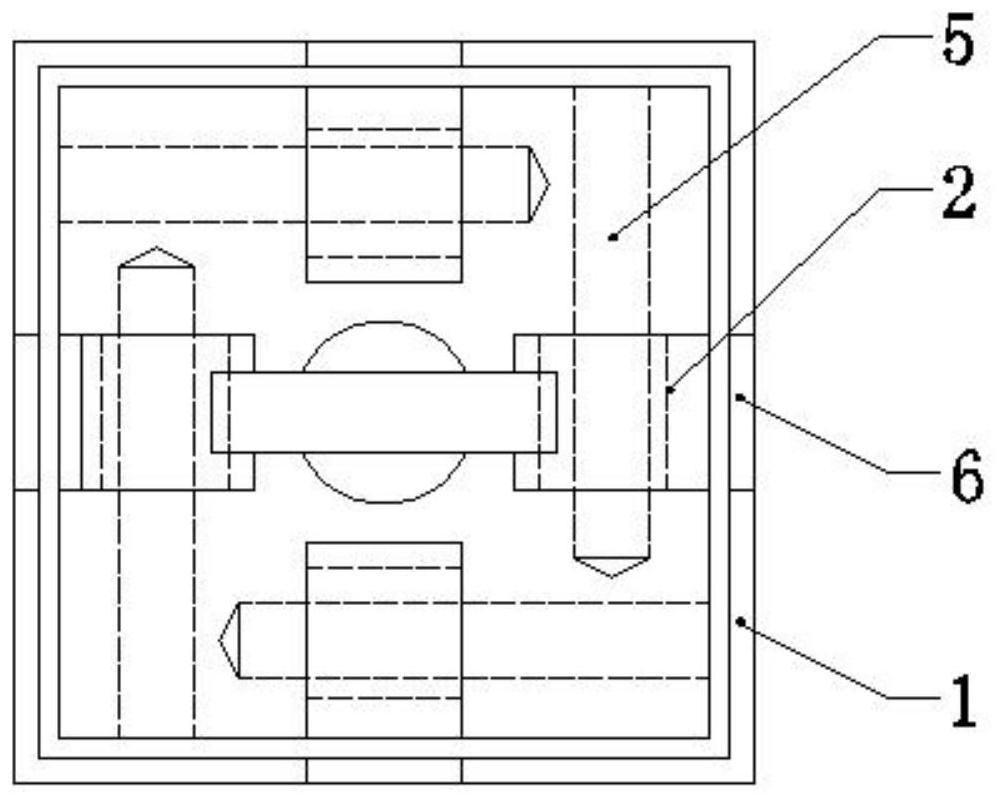

[0033] refer to Figure 1-12 As shown, this embodiment is a new type of quick self-decoupling device, which includes a column sleeve 1, a solid cylinder 3, a lifting claw 2, a lifting lug 4 and a positioning pin 5. The inside of the column sleeve 1 is provided with a cavity for the vertical displacement of the solid column 3, the upper center of the solid column 3 is fixed with a lifting lug 4, and the upper periphery of the solid column 3 is uniformly provided with a gap, and the gap is along the horizontal direction. A positioning pin 5 is fixed, and the outer side of the positioning pin 5 is provided with a hanging claw 2 that can rotate along a vertical plane.

[0034] In this embodiment, the column cover 1 is fixed on the hoisting object 7, such as by welding. The column cover 1 is a quadrangular prism, and the corresponding solid column 3 is a quadrangular prism. The lifting lug 4 is detachably connected to the solid cylinder 3 by means of screw connection.

[0035] I...

Embodiment 2

[0038] The structure and application of this embodiment are basically the same as those of Embodiment 1, the difference is that the column sleeve 1 is a cylindrical sleeve, and the solid cylinder 3 is a cylinder with notches on its periphery.

Embodiment 3

[0040] The structure and application of this embodiment are basically the same as those of the second embodiment. The column sleeve 1 is a cylindrical sleeve, and the solid cylinder 3 is a cylinder with notches on its periphery. Considering that the cylinder is easy to rotate, an anti-rotation convex key is provided in the inner cavity wall of the cylinder sleeve, and an anti-rotation key groove is provided on the outer wall of the cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com