Polymerization initiator composition, preparation method therefor, and method for preparing polymer using same

一种聚合引发剂、组合物的技术,应用在氨基化合物制备、有机化合物的制备、化学仪器和方法等方向,达到改善转化率、防止物理性质降解的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0228] The method of preparing a polymerization initiator according to the present invention may further include a step of reacting the prepared modified initiator and a conjugated diene compound after the step of preparing a modified initiator.

[0229] In one example, as the conjugated diene compound, 1,3-butadiene (BD), isoprene (IP), 2,3-dimethyl-1,3-butadiene, 1 , one or more of 3-pentadiene, 3-methyl-1,3-pentadiene, 1,3-heptadiene and 1,3-hexadiene, specifically, 1, 3-butadiene or isoprene. The conjugated diene compound can be reacted in the form of a solution of the conjugated diene compound including a solvent. As the solvent, any solvent may be used as long as it is generally available. Specifically, cyclohexane, hexane, tetrahydrofuran, diethyl ether, and the like can be used, more specifically, cyclohexane can be used.

[0230] For example, the concentration of the conjugated diene compound solution may be 1 to 100 wt%, and the balance may be a solvent. Specific...

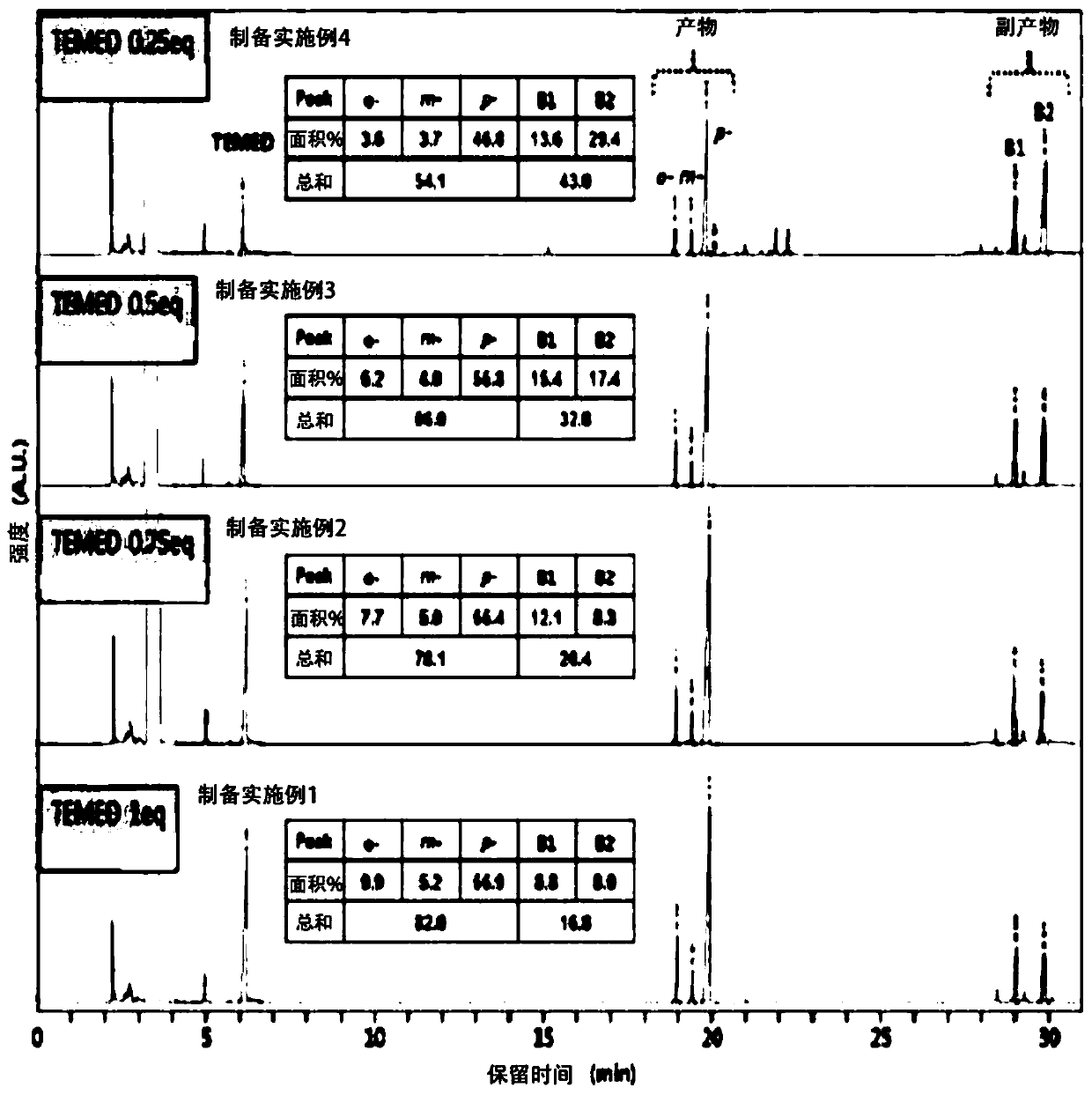

preparation Embodiment 1

[0293] Prepare two vacuum-dried stainless steel pressure vessels. 2477g hexane, 15g 2-vinyl-N,N-dimethylbenzylamine, 5g 3-vinyl-N,N-dimethylbenzylamine, 80g 4-vinyl-N,N-dimethyl Benzylamine and 72 g of tetramethylethylenediamine were placed in the first pressure vessel to prepare a vinyl-N,N-dimethylbenzylamine solution. Then, 171 g of 2.5M liquid n-butyllithium and 2478 g of hexane were placed in another pressure vessel to prepare an n-butyllithium solution.

[0294] The pressure of each pressure vessel was maintained at 4 bar. Then, the vinyl-N,N-dimethylbenzylamine solution was injected into the first inflow line at 10.0 g / min, and the n-butyllithium solution was injected into the second inflow line at 10.0 g / min using a mass flow meter, wherein The individual streams meet at a T-junction or Y-channel. At this point, the width of the tube or channel is 1 / 8 inch, the temperature is maintained at -30°C, and the internal pressure is maintained at 2 bar by use of a back pres...

preparation Embodiment 2

[0296] A polymerization initiator composition was prepared in the same manner as in Preparation Example 1, except that 2495 g of hexane and 54 g of tetramethylethylenediamine were added to the first pressure vessel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com