PCB connecting plate welding fixture for charger production

A welding fixture and charger technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor use effect and large space occupied by students, and achieve improved anti-skid ability, good cushioning performance, smooth transition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

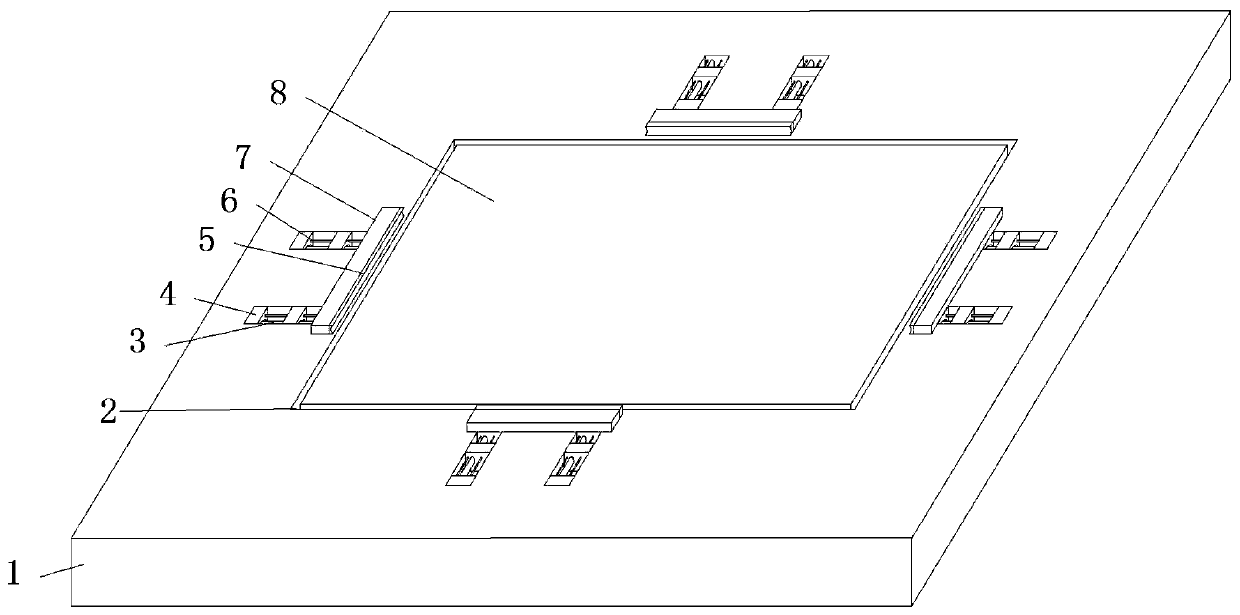

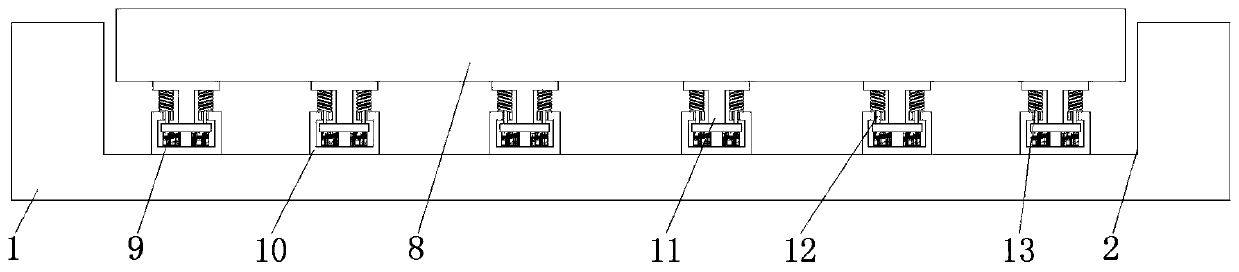

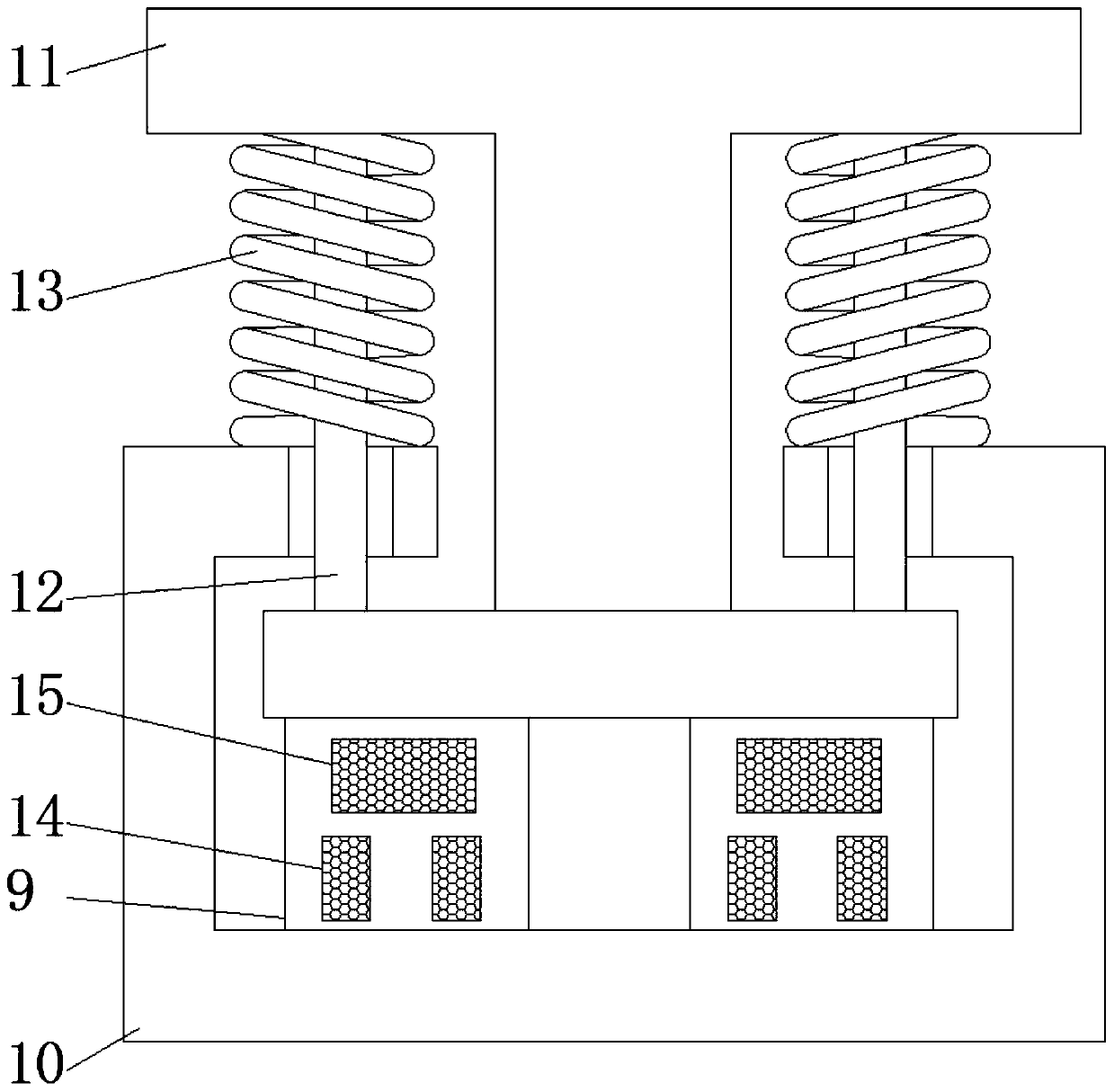

[0019] see Figure 1-3 , this embodiment provides a PCB connecting board welding fixture for charger production, including a base plate 1, a limiting groove 2 is provided in the center of the top of the base plate 1, a workbench 8 is arranged on the inner side of the limit groove 2, and the bottom of the workbench 8 Evenly arranged I-shaped blocks 11 are installed, and the inner side of the I-shaped block 11 is provided with a guide rod 12, the top of the guide rod 12 is nested with a spring 13, and the bottom end of the guide rod 12 runs through the chuck 10, and the chuck 10 The inner side is provided with two buffer columns 9, the interior of the buffer column 9 is provided with an upper cavity 15, and the lower cavity 14 is provided below the upper cavity 15, and the interiors of the lower cavity 14 and the upper cavity 15 are completely filled with rubber. Particles, the top of the buffer column 9 is fixedly installed with the I-shaped block 11, the outer edge of the limi...

Embodiment 2

[0022] see Figure 1-3 On the basis of Embodiment 1, a further improvement has been made: both sides of the top of the chuck 10 are provided with through holes, which are convenient for installation and clamping, and the through holes are inserted into the guide rod 12 to ensure the stability of the installation. The positioning block 7 There are four of them, and they are arranged opposite to each other, which improves the force uniformity of the PCB connecting board.

[0023] Wherein, one side of the rubber pad 5 is provided with a semi-circular groove, which is convenient for limit engagement on the side of the PCB connecting board and improves the clamping tightness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com