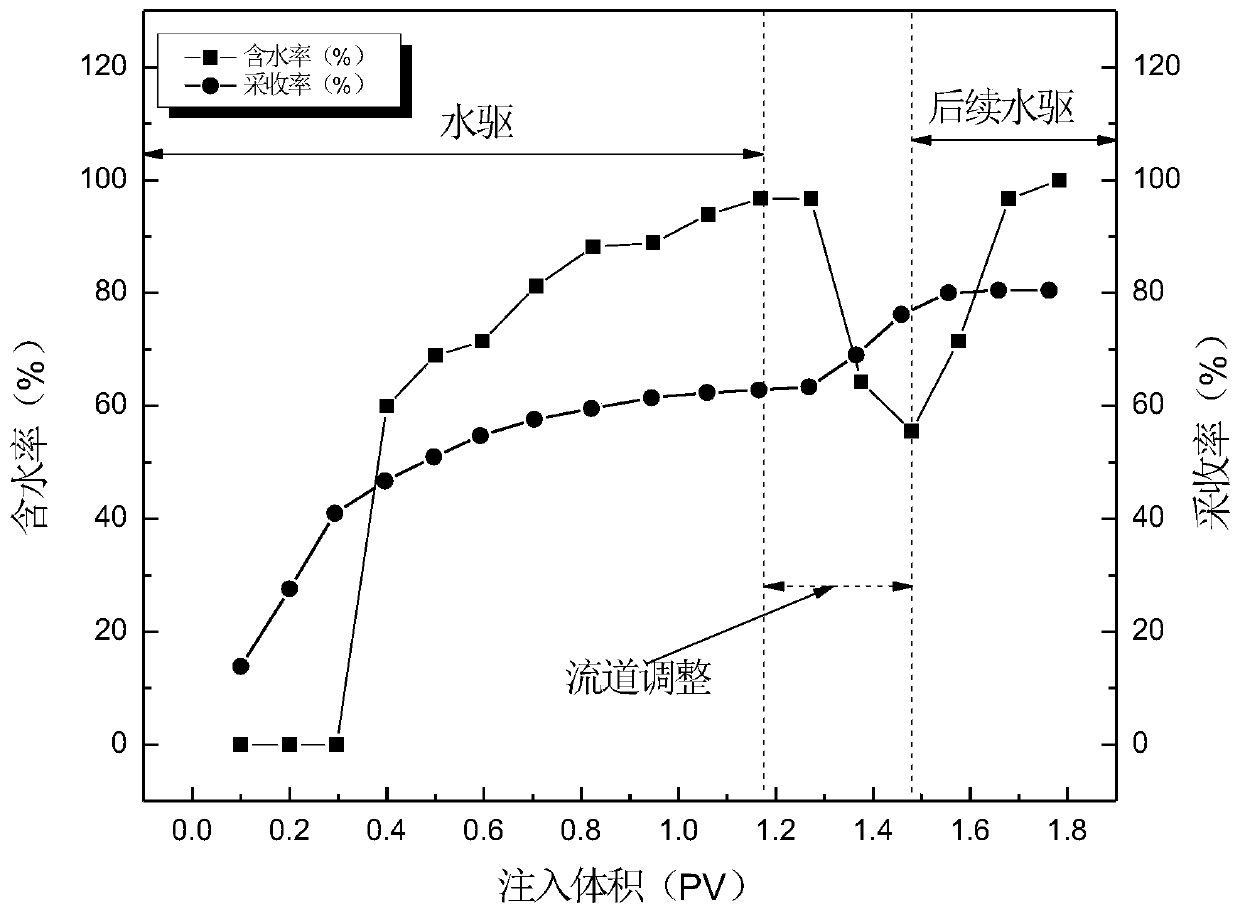

A slow-swelling and density-controllable flow channel adjustment agent system for fracture-vuggy reservoirs and its preparation method

A slit-hole type, adjustment technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of reduced strength performance, structural damage, poor stability of plugging agents, etc., and achieves low expansion multiples and good flow channels. Adjustment effect, good temperature resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

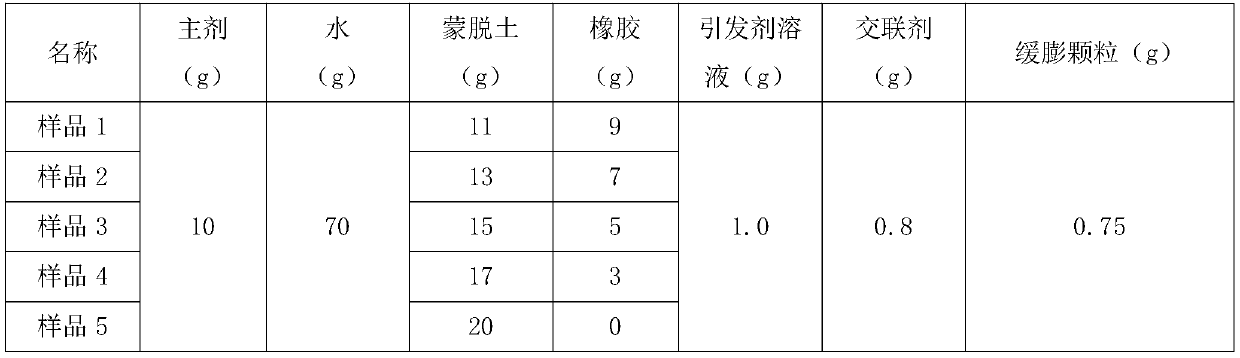

[0030] A1: Preparation of montmorillonite dispersion system

[0031] Add 11g of montmorillonite into 70g of aqueous solution, and stir for 4h to 5h, so that the montmorillonite is well dispersed in water to obtain a montmorillonite dispersion system.

[0032] A2: Preparation of main agent solution

[0033] Add the main agent of 9g acrylamide and 1g of acrylic acid configuration, 0.8g phenolic crosslinking agent and 1g concentration of 1% azobisisobutyronitrile initiator and 0.75g lithium soap nanoparticles to the montmorillonite prepared in step A1 Dispersion system, stirring evenly, so that several reagents and lithium soap nanoparticles can be well dissolved into the montmorillonite dispersion system to obtain the main agent solution.

[0034] A3: Preparation of slow-swelling density-controllable flow channel regulator

[0035] Put the main agent solution prepared in step A2 into a 90°C oven to form a gel for 1.5 hours, take it out, add 9g of rubber particles and stir even...

Embodiment 2

[0040] A1: Preparation of montmorillonite dispersion system

[0041] Add 15g of montmorillonite into 69g of aqueous solution, and stir for 4h to 5h, so that the montmorillonite is well dispersed in water to obtain a montmorillonite dispersion system.

[0042] A2: Preparation of main agent solution

[0043] Add the main agent of 9g acrylamide and 1g of acrylic acid configuration, 0.8g phenolic crosslinking agent and 1g concentration of 1% azobisisobutyronitrile initiator and 0.75g lithium soap nanoparticles to the montmorillonite prepared in step A1 Dispersion system, stirring evenly, so that several reagents and lithium soap nanoparticles can be well dissolved into the montmorillonite dispersion system to obtain the main agent solution.

[0044] A3: Preparation of slow-swelling density-controllable flow channel regulator

[0045] Put the main agent solution prepared in step A2 into a 90°C oven to form a gel for 1.5 hours, take it out, add 6g of rubber particles and stir even...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com