Yarn tension adjusting device and application method thereof

A technology for adjusting device and yarn tension, which is applied in the field of yarn tension adjusting device and yarn tension adjustment, which can solve the problems of low efficiency of tension adjustment, large consumption of manpower and material resources, reduction of physical properties of fiber ropes, etc., and achieve uniform tension adjustment , High tension adjustment efficiency, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

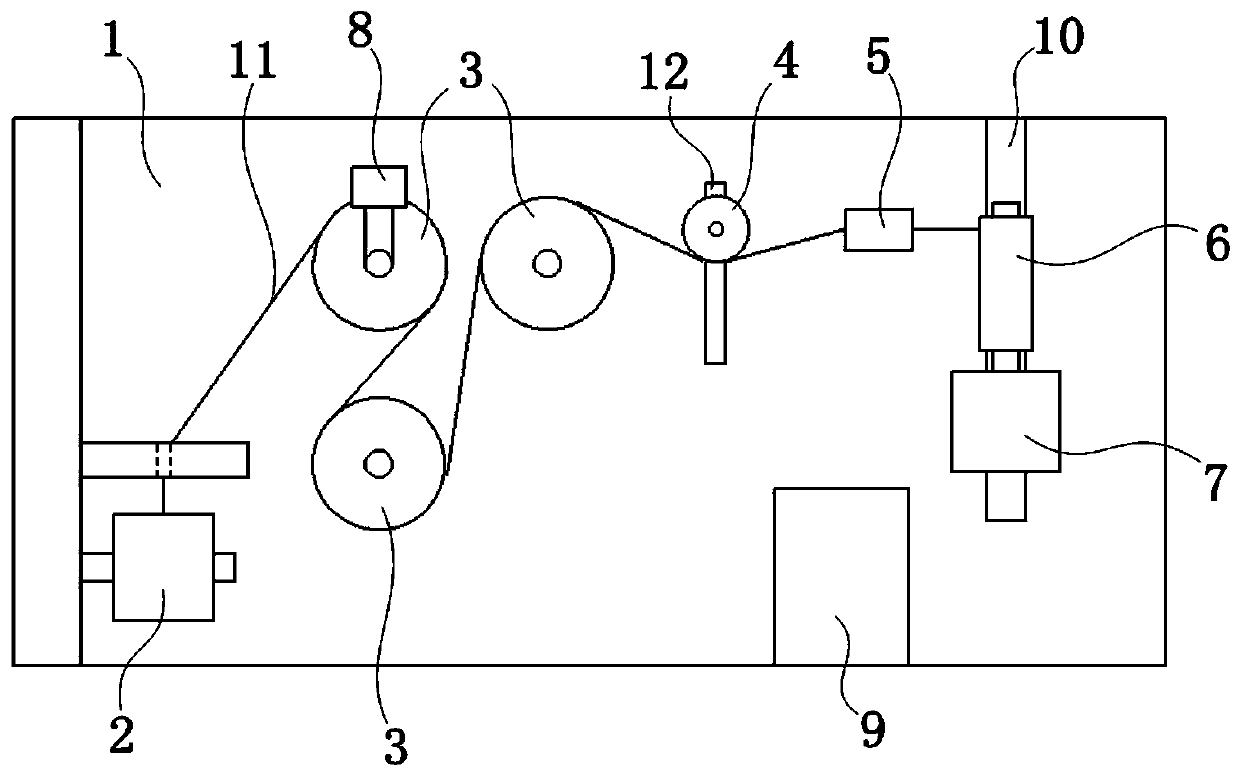

[0054] Step S1: Check the safety of the circuit to ensure that there is no potential safety hazard.

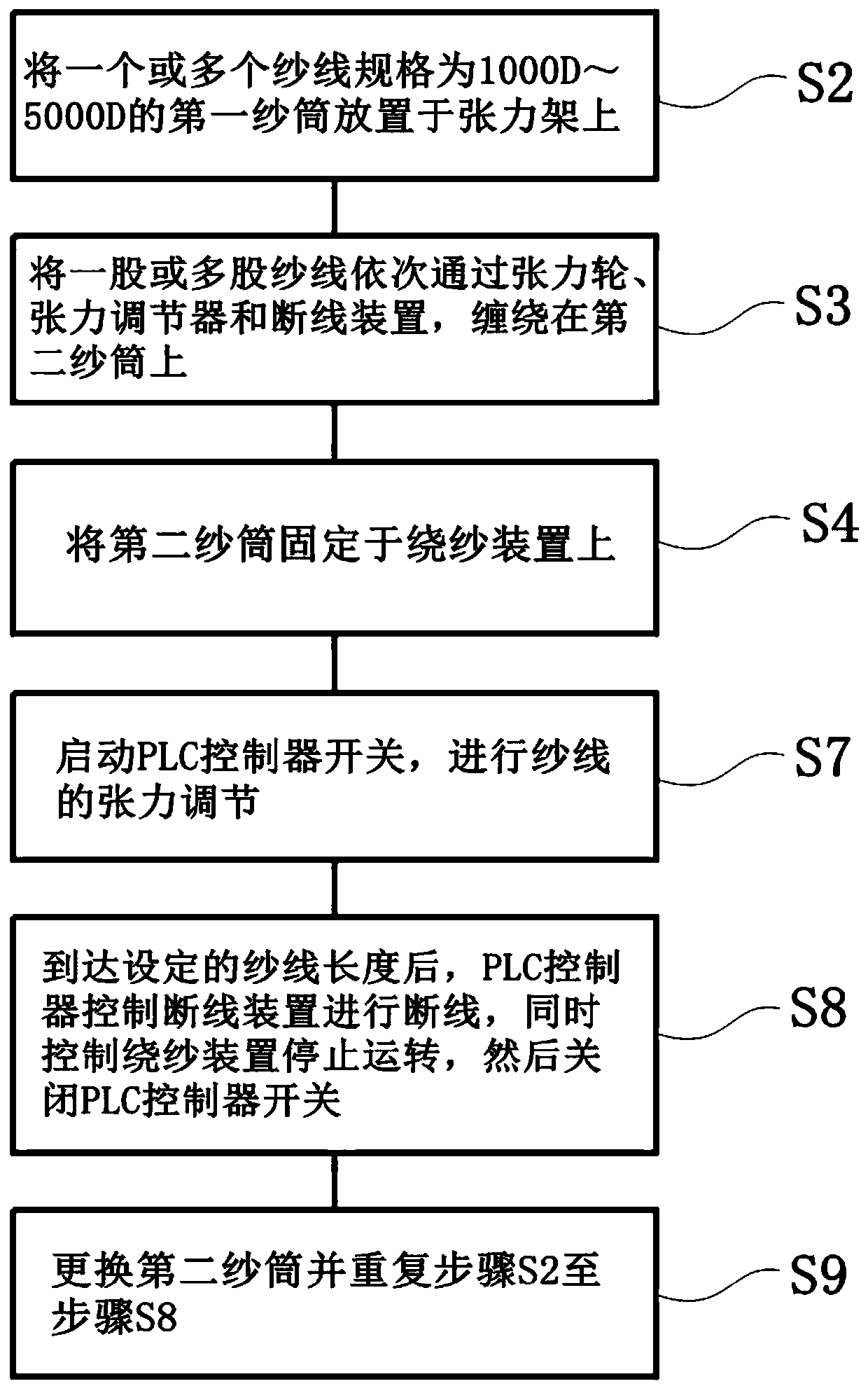

[0055] Step S2: Place a first yarn bobbin with a yarn specification of 5000D on the tension frame. And pass the yarn through the porcelain eye on the corresponding tension frame.

[0056] Step S3: passing one strand of yarn through the tension wheel, the tension regulator and the thread breaking device in sequence, and winding it on the second yarn bobbin.

[0057] Step S4: Fix the second yarn bobbin on the rotating shaft on the yarn winding device.

[0058] Step S5: Set the force of the tension regulator on the yarn to be 10N.

[0059] Step S6: Set the required yarn length to 500 meters on the PLC controller.

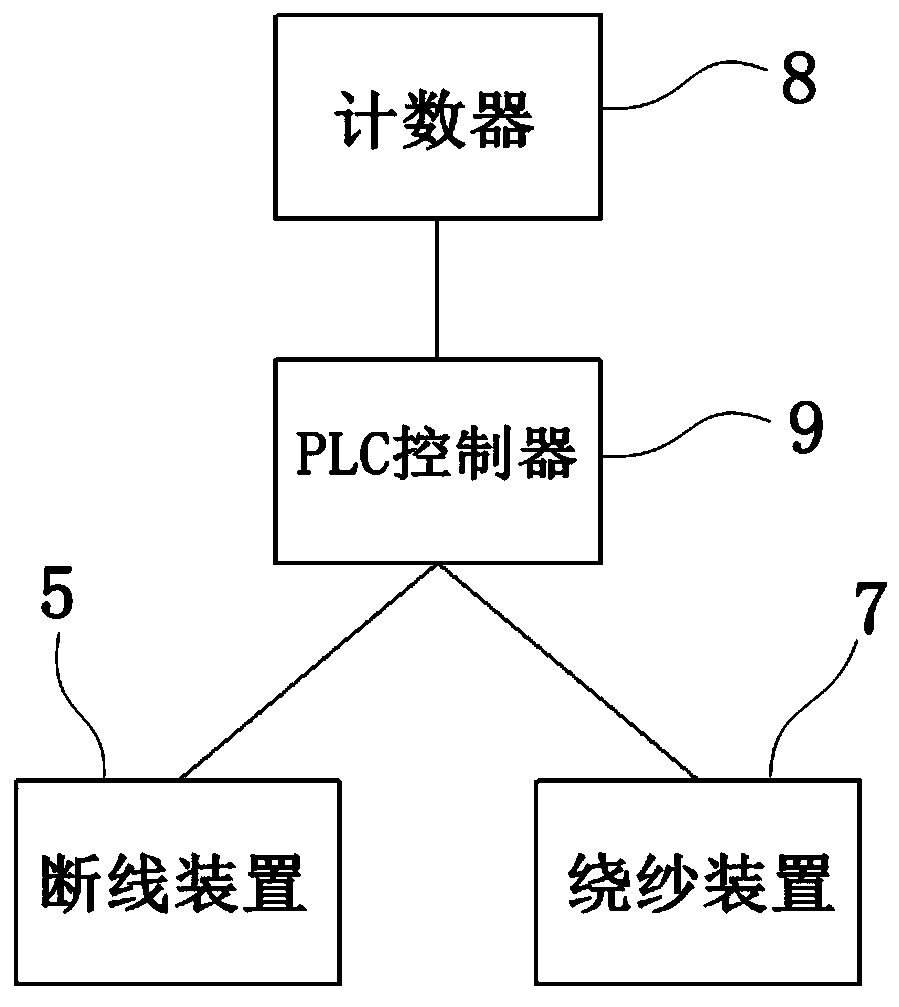

[0060] Step S7: Start the switch of the PLC controller, the counter and the yarn winding device start to work, and start to adjust the tension of the yarn.

[0061] Step S8: After reaching the set yarn length, the PLC controller controls the thread breaking device ...

Embodiment 2

[0064] Step S1: Check the safety of the circuit to ensure that there is no potential safety hazard.

[0065] Step S2: Place two first bobbins with a yarn specification of 2000D on the tension frame. And pass the yarn through the porcelain eye on the corresponding tension frame.

[0066] Step S3: the two strands of yarn pass through the tension wheel, the tension regulator and the thread breaking device in sequence, and are wound on the second yarn bobbin.

[0067] Step S4: Fix the second yarn bobbin on the rotating shaft on the yarn winding device.

[0068] Step S5: Set the force of the tension regulator on the yarn to be 5N.

[0069] Step S6: Set the required yarn length to 1000 meters on the PLC controller.

[0070] Step S7: Start the switch of the PLC controller, the counter and the yarn winding device start to work, and start to adjust the tension of the yarn.

[0071] Step S8: After reaching the set yarn length, the PLC controller controls the thread breaking device t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com