Combustion equipment

A combustion equipment and combustion chamber technology, applied in burners, combustion methods, combustion control and other directions, can solve the problems of waste gas discharge to pollute the environment, insufficient gas combustion, low energy conversion, etc., to avoid pollution, easy operation, and reduce nitrogen. Effect of sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

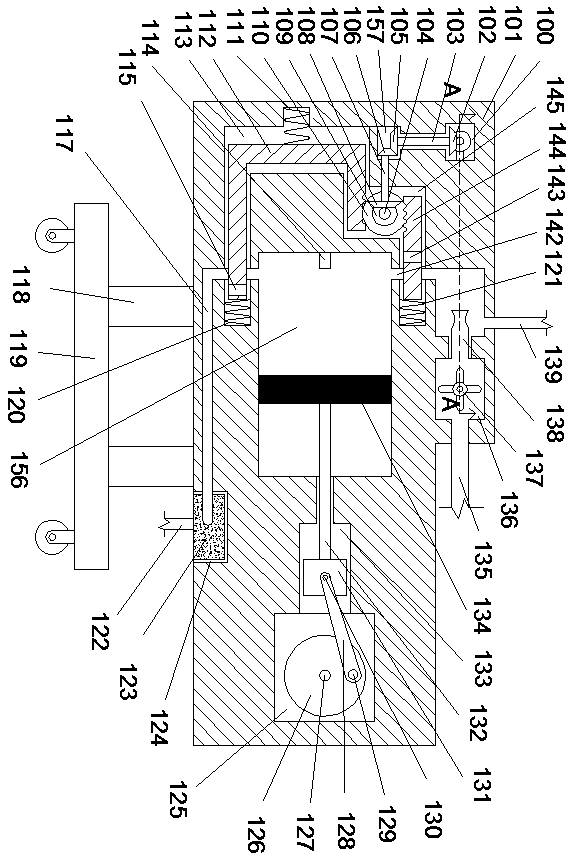

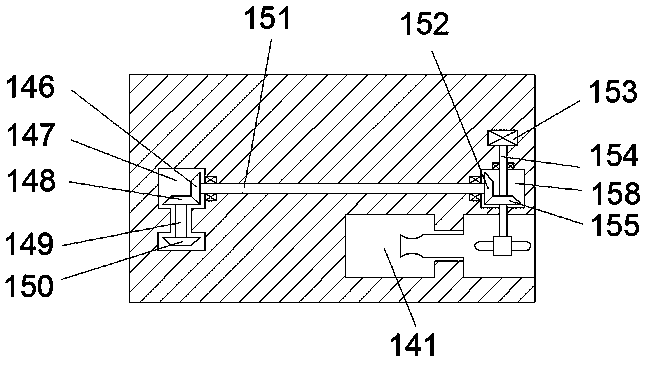

[0017] Combine below Figure 1-2 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0018] refer to Figure 1-2 , a combustion device of the present invention, comprising a body 101 and a first gear meshing chamber 100 extending forward and backward inside the body 101, a fan power assembly is arranged in the first gear meshing chamber 100, and the first The right side of a gear meshing chamber 100 is provided with an oil-air mixing chamber 141, and the right side of the oil-air mixing chamber 141 is communicated with a fan chamber 136, and the oil-air mixing chamber 141 and the fan chamber 136 are jointly provided with an oil-air mixing assembly. The fan power assembly provides working power for the oil-air mixing assembly. A second gear engagement chamber 157 is p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap