Auxiliary mechanical device suitable for fixed sensor and fixing method

A technology of auxiliary machinery and sensors, applied in measuring devices, using sonic/ultrasonic/infrasonic waves to analyze solids, instruments, etc., can solve problems such as affecting the accuracy of detection results, increasing the detection process time, and complex tunnel construction conditions. Signal acquisition, easy to carry, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

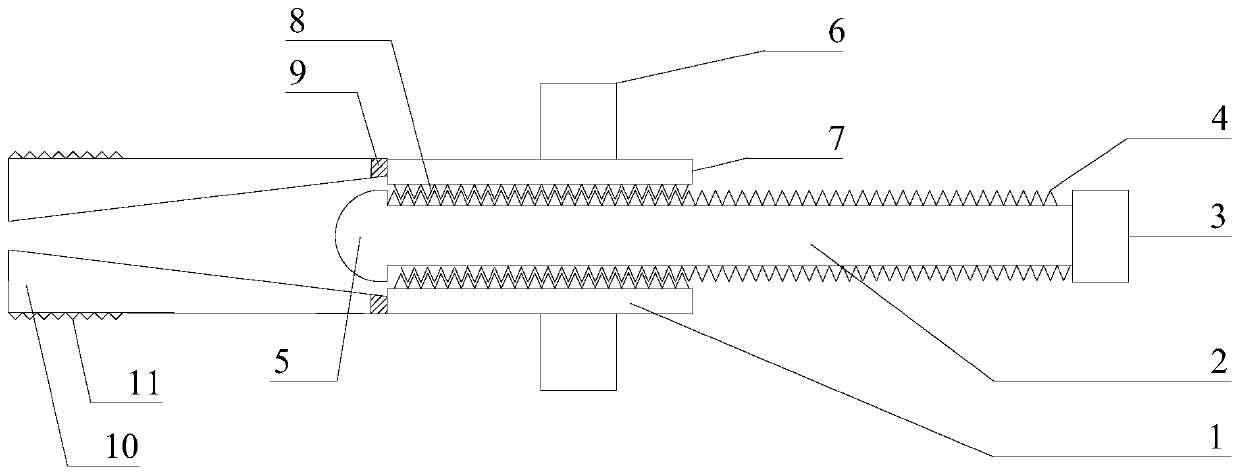

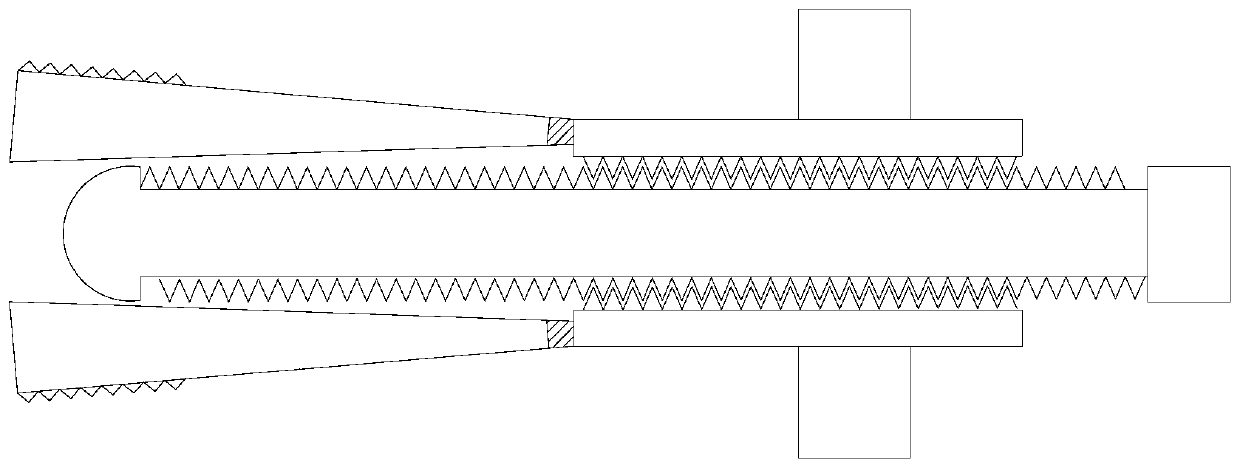

[0037] An auxiliary mechanical device suitable for fixing a sensor disclosed in this embodiment includes screwing expansion bolts and a sensor pressing device;

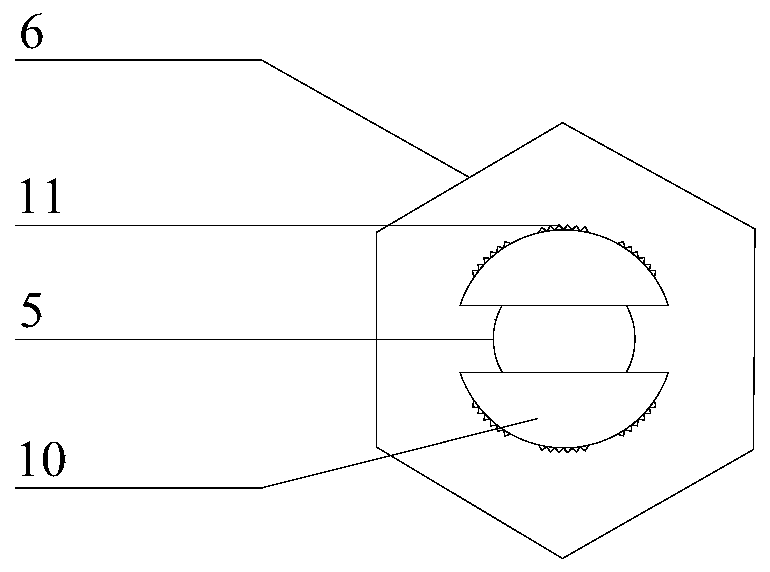

[0038] Screwing the expansion bolt includes a screwing nail and a connecting sleeve; the outer ring of the screwing nail is threadedly matched with the inner ring of the connecting sleeve, and one end of the screwing nail is a hemispherical nail head. One end of the sleeve is connected with an expansion friction plate, and the hemispherical nail head of the screw is inserted from the other end of the connecting sleeve; a hexagonal fixing ring is arranged in the middle of the connecting sleeve;

[0039] The sensor pressing device includes two fixing parts, each fixing part is provided with a mounting hole for the screwed expansion bolt to pass through; an elastic belt storage box is arranged inside the two fixing parts, and each elastic belt is stored The box is provided with a rotating shaft, and a fixed shaft is inse...

Embodiment 2

[0055] Utilize the device described in embodiment 1 to fix the method for sensor, as follows:

[0056] A. Mark all the positions where sensors 23 need to be deployed according to the site conditions;

[0057] B. Take the pre-marked sensor 23 layout position as the center, and use an 18 mm percussion drill bit to symmetrically drill two holes with a distance of less than 20 cm parallel to the direction of the face;

[0058] C. Pass the screwed expansion bolt 1 through the hexagonal fixing hole 13 and the round through hole 14 on one side of the sensor pressing device 20, and use a hexagonal wrench to rotate the screwing nail 2 to fix the screwed expansion bolt 1, thereby fixing the sensor pressing device 20 sides;

[0059] D. Pull out the elastic band 19, move the other side of the sensor pressing device 20 to the top of another drill hole, and repeat step C;

[0060] E. Press the sensor 23 wrapped with coupling agent to the pre-marked sensor 23 layout position through the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com