Driving mechanism and dough mixer

A technology of driving mechanism and driving parts, which is applied to the structural components of mixing/kneading machines, dough mixers, baking, etc. It can solve the problems of reducing the transmission effect of worms and gears, eccentricity, and large force, so as to reduce tooth collapse risk, ensure transmission efficiency, and improve bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

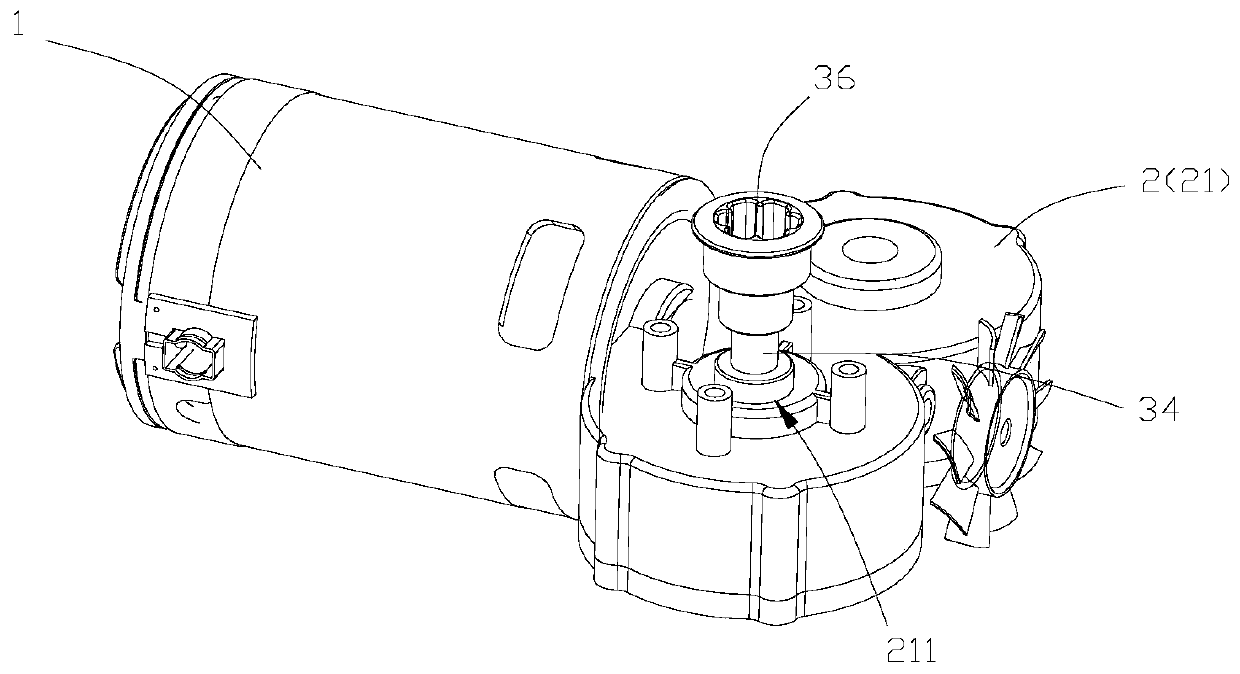

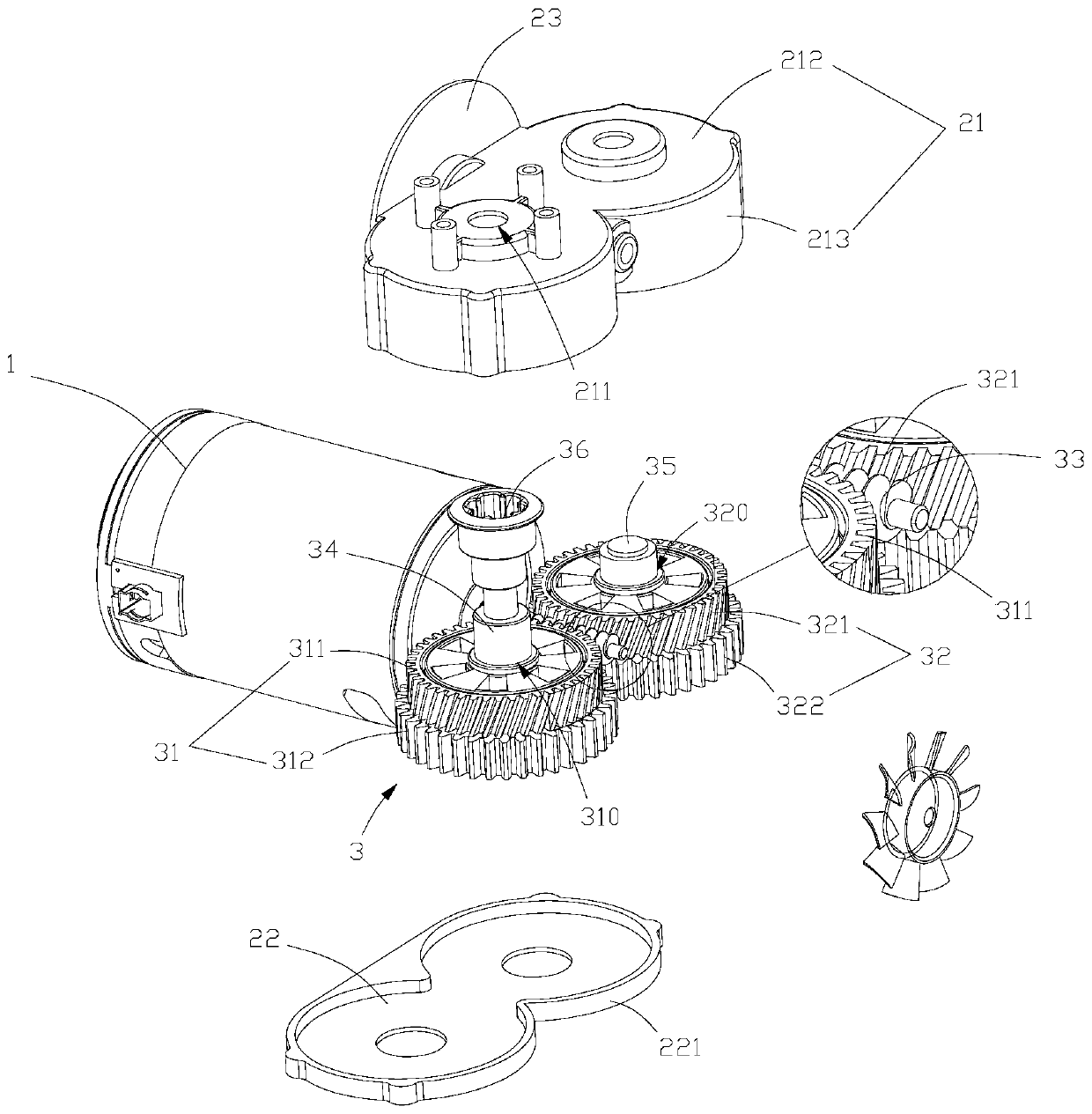

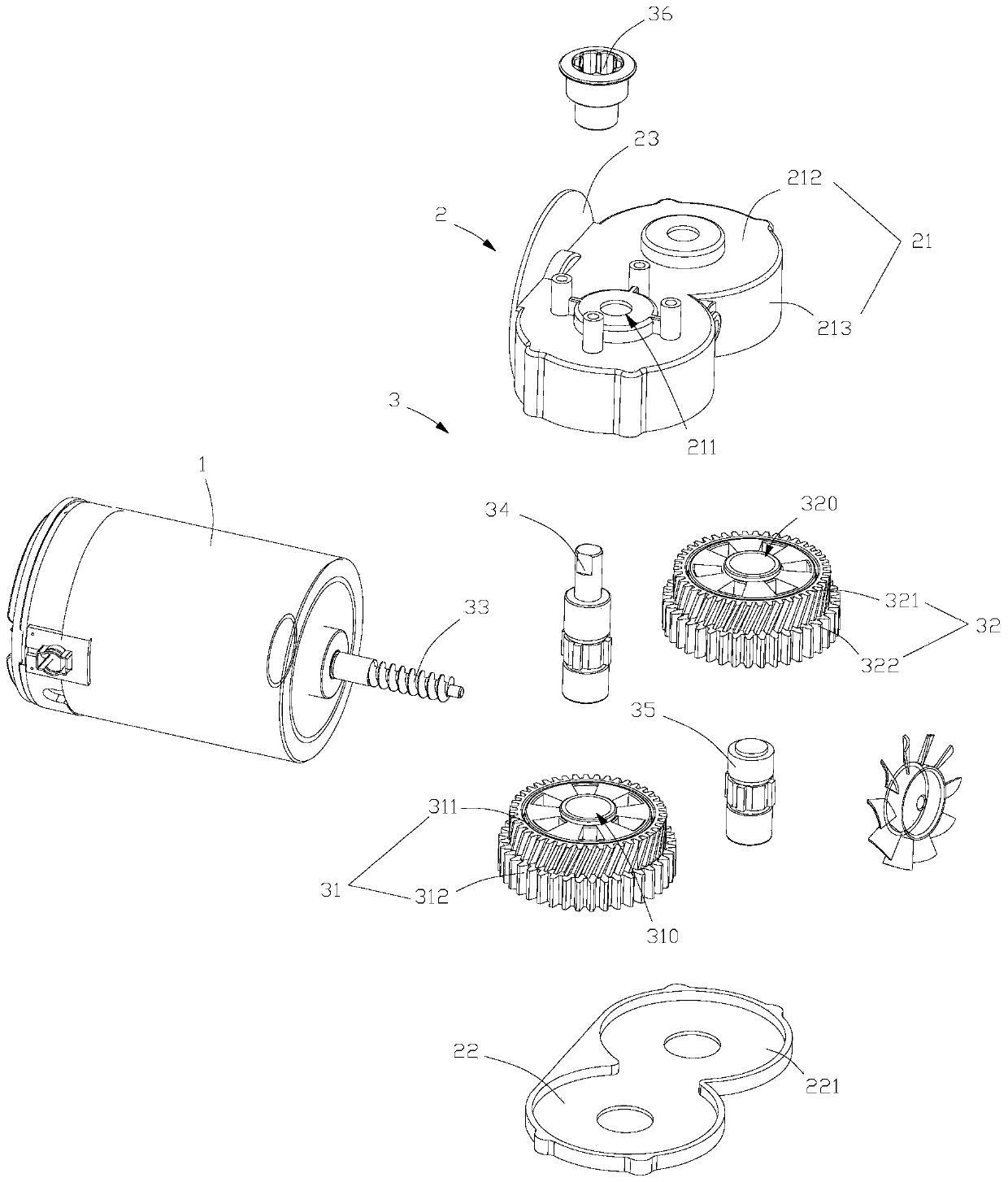

[0025] see Figure 1 to Figure 4 , the present embodiment provides a driving mechanism, including a motor 1, a fixed seat 2, a transmission assembly 3, a first key shaft 34, a second key shaft 35 and a driving member 36, and the transmission assembly 3 includes a worm 33, which is arranged on the The first duplex gear 31 and the second duplex gear 32 on the opposite sides of the worm 33, the worm 33 is driven to rotate by the motor 1, specifically, the side of the fixed seat 2 is provided with a 33 is inserted into the assembly hole of its inner cavity (not shown in the assembly hole figure), the worm 33 is installed in the holder 2 through the assembly hole, and the first dual gear 31 and the second dual gear 32 can be It is rotatably installed on both sides of the inner cavity of the fixed seat 2, and the package of the first double gear 31 and the second double gear 32 is facilitated by setting the fixed seat 2, thereby improving the integrity and compactness of the equipme...

Embodiment 2

[0035] see Figure 1 to Figure 6 , this embodiment provides a dough mixer using the driving mechanism 30 of the first embodiment, which includes a base 10 and a pot body 20, the pot body 20 is arranged on the upper side of the base 10, and the driving mechanism of the first embodiment is arranged inside the base 10 30, the bottom of the pot body 20 is provided with a stirring member (the stirring member is not shown in the figure), the upper side of the base 10 is provided with a gap 101 corresponding to the driving member 36, and the driving member 36 passes through the gap 101 and The stirring parts are connected, and since the dough mixer adopts the drive mechanism 30 of the present invention, it not only reduces the risk of chipping, but also ensures that once the main output gear 311 chipping occurs, the equipment can continue to operate, thereby improving User experience.

[0036] see Figure 1 to Figure 6 , the motor 1 is horizontally placed in the base 10 along its a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com