Liquid crystal alignment agent, liquid crystal alignment film and liquid crystal display element

A monomer and composition technology, applied in the field of liquid crystal display elements, can solve the problems of low solubility and difficult application of liquid crystal alignment agents, etc., and achieve the effect of excellent tilt angle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

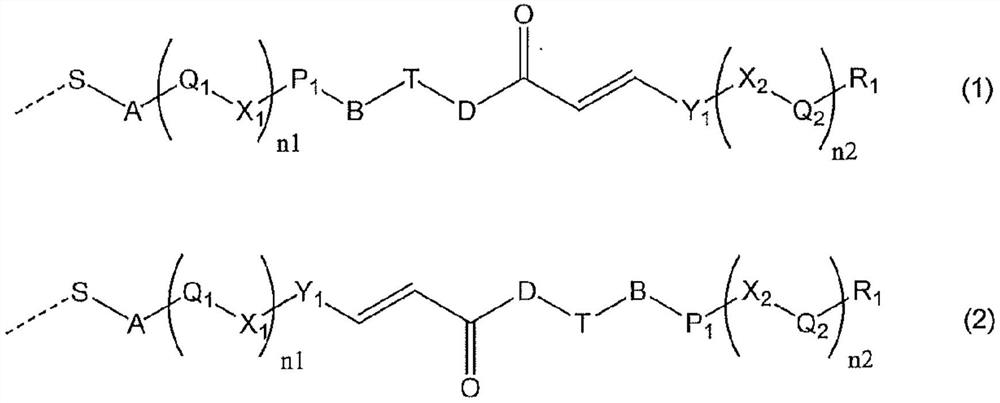

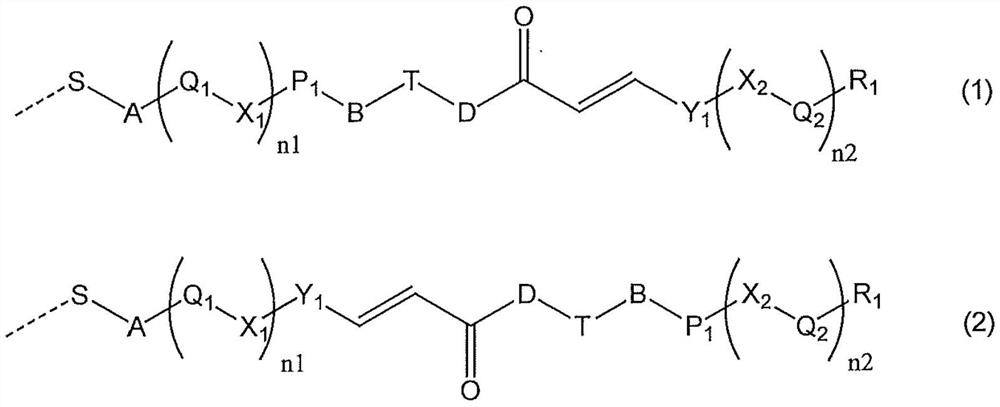

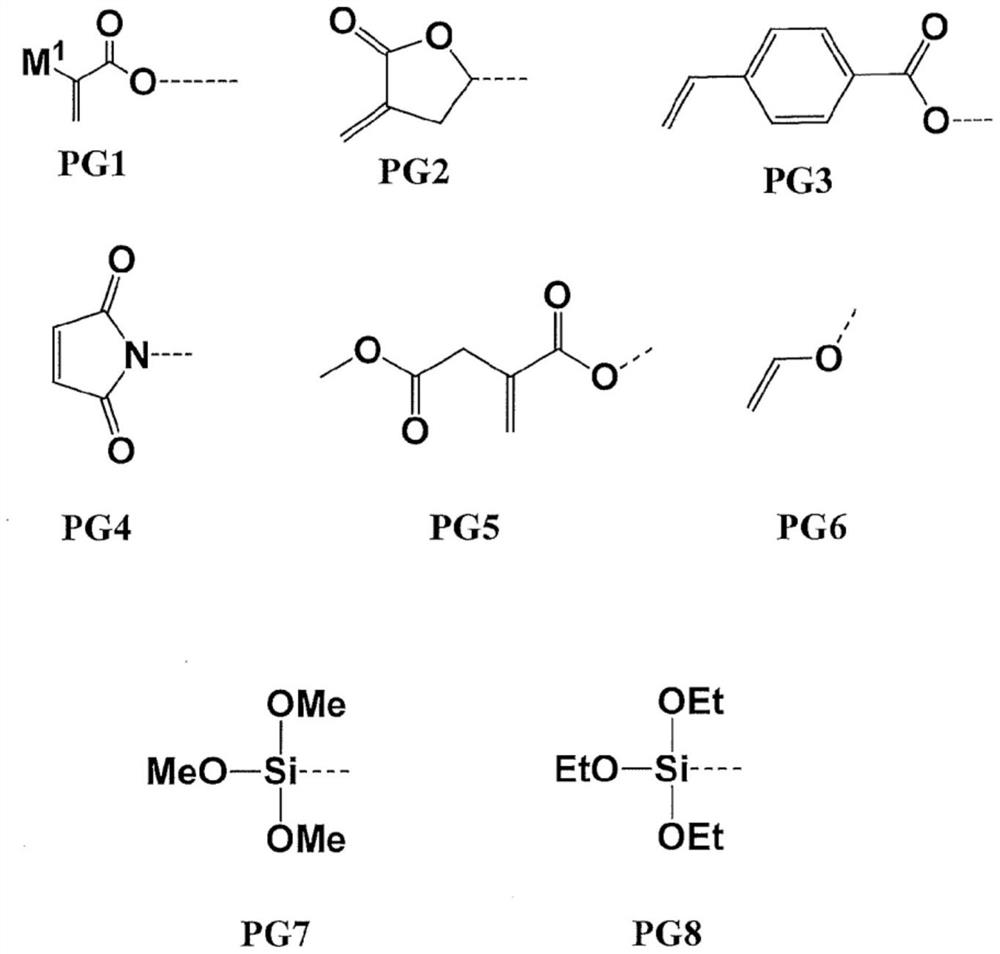

Method used

Image

Examples

preparation example Construction

[0152] [Preparation of liquid crystal aligning agent]

[0153] It is preferable to prepare the liquid crystal aligning agent used for this invention as a coating liquid so that it may become suitable for formation of a liquid crystal aligning film. That is, it is preferable to prepare the liquid crystal aligning agent used by this invention as the solution which melt|dissolved the resin component for forming a resin film in an organic solvent. Here, the resin component refers to a resin component containing the side chain type polymer as the (A) component explained above. In this case, the content of the resin component is preferably 1% by mass to 20% by mass, more preferably 3% by mass to 15% by mass, particularly preferably 3% by mass to 10% by mass.

[0154] In the liquid crystal aligning agent of this invention, all the said resin components may be side chain type polymers which are (A) component, and other polymers other than these may be mixed in the range which does no...

Embodiment

[0226] Abbreviations used in Examples are as follows.

[0227]

[0228]

[0229] MA-1 was synthesized by the synthesis method described in the non-patent literature (Macromolecules 2002, 35, 706-713).

[0230] MA-2 was synthesized using the synthesis method described in British Patent GB2306470B.

[0231] MA-3 was synthesized by the synthesis method described in the non-patent literature (Macromolecules 2007, 40, 6355-6360).

[0232] MA-4 was synthesized by the synthesis method described in the pamphlet of International Patent Application Publication WO2014 / 054785.

[0233] MA-5 was synthesized by the synthesis method described in the patent document (Japanese Patent Application Laid-Open No. 9-118717).

[0234] MA-6 was purchased and used by Tokyo Chemical Industry Co., Ltd.

[0235] MA-7 was purchased and used by Tokyo Chemical Industry Co., Ltd.

[0236] MA-8 was purchased and used by Tokyo Chemical Industry Co., Ltd.

[0237] MA-9 was purchased and used by Sigma ...

Synthetic example 1

[0249]

[0250] After dissolving MA-1 (21 g: 40 mmol) and MA-2 (26 g: 60 mmol) in THF (270 g) and degassing with a diaphragm pump, AIBN (0.5 g: 3 mmol) was added and degassed again. Then, it was made to react at 60 degreeC for 6 hours, and the polymer solution of the methacrylate was obtained. This polymer solution was added dropwise to methanol (2000 ml), and the resulting precipitate was filtered. This precipitate was washed with methanol, and dried under reduced pressure to obtain methacrylate polymer powder P1.

[0251] Under the conditions shown in Table 1, methacrylate polymer powders P2 and P3 were produced by the method similar to the synthesis example 1 also about the synthesis examples 2 and 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com