Biological antifugal liquid preparation with microorganism pythium oligandrum and method of production

A technology of Pythium oligandrum and microorganisms, which is applied in the field of producing the product, can solve the problems of not being disclosed, and achieve the effect of simple application, long-term and significant stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

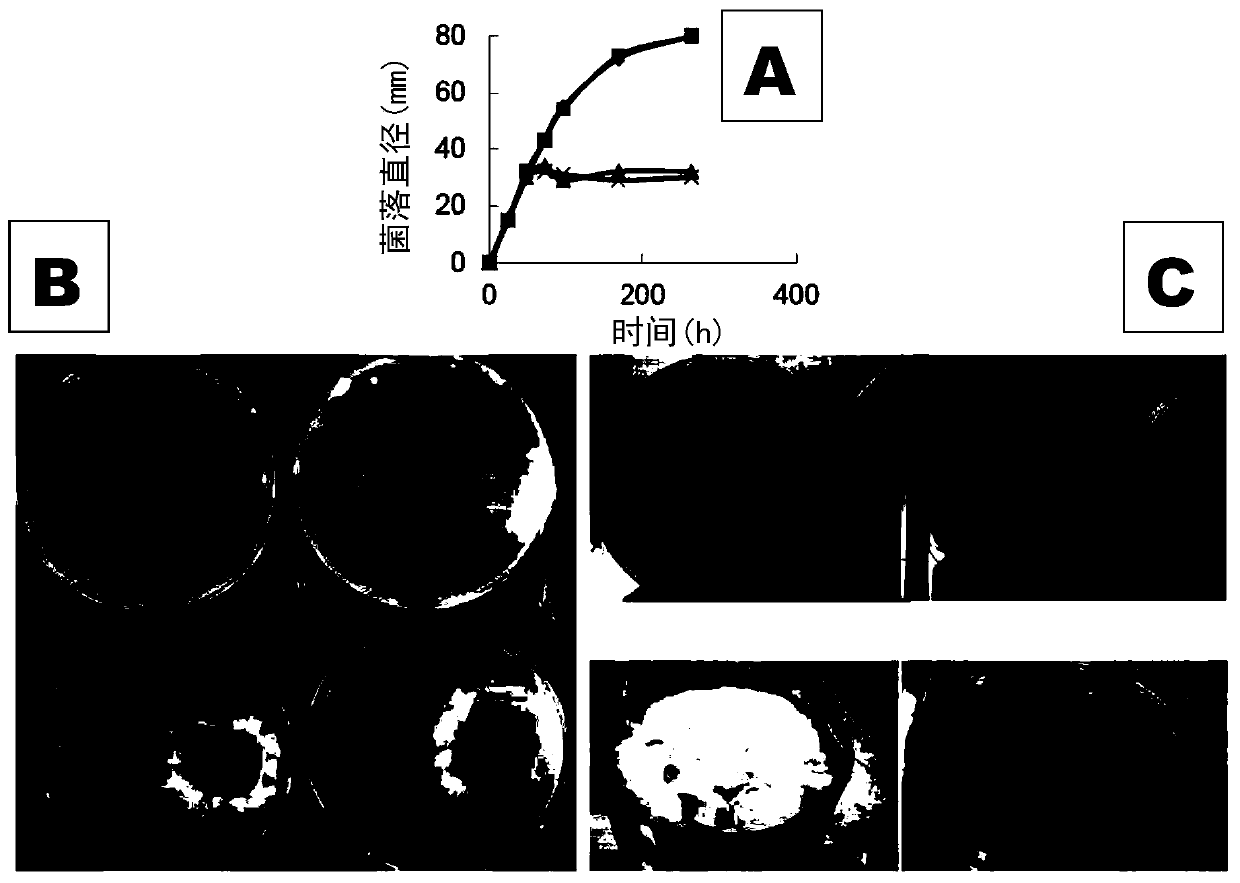

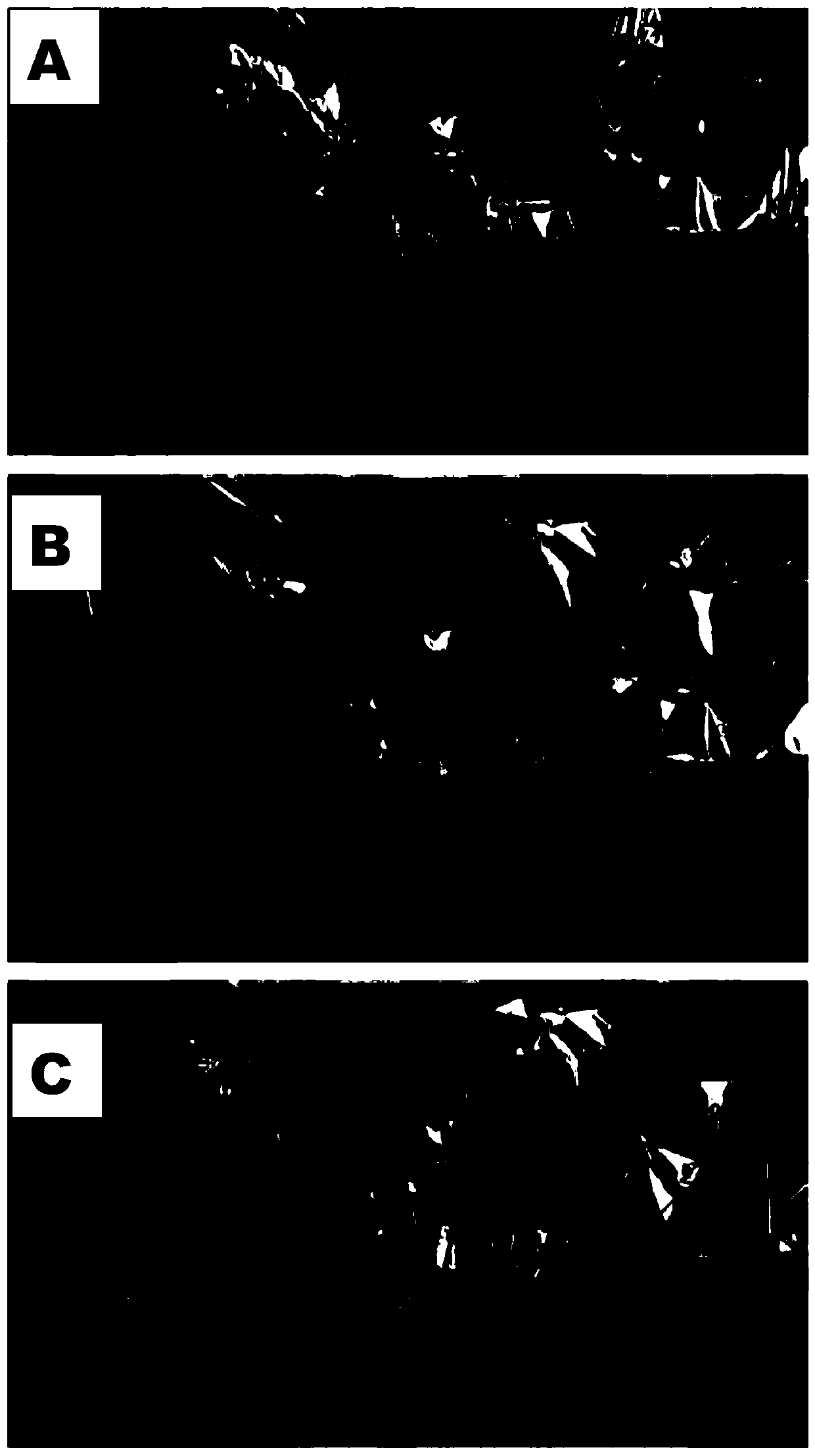

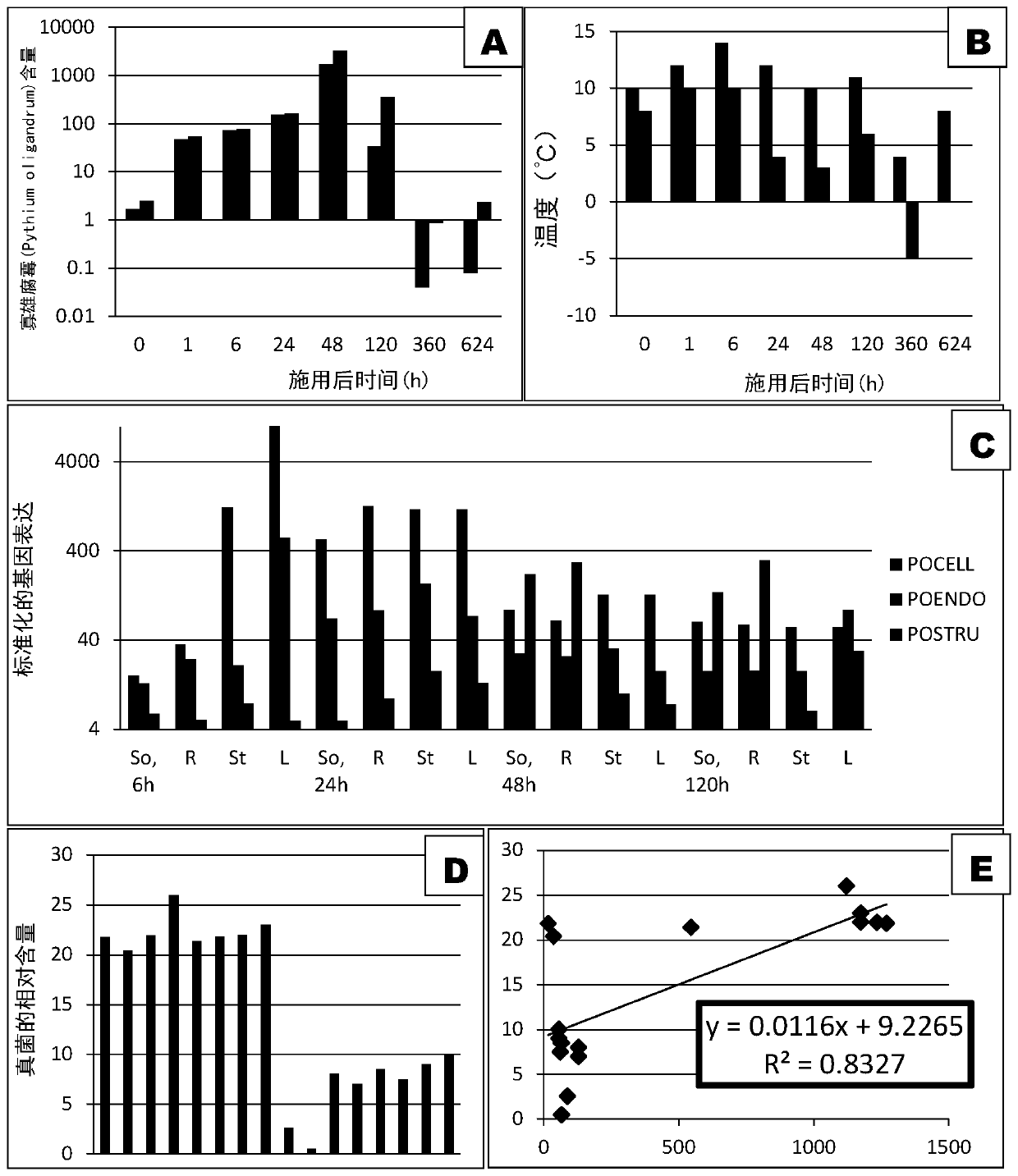

Image

Examples

Embodiment 1

[0065] Liquid bioantifungal preparation for spraying crops with a high percentage by weight of biomass

[0066] preparation:

[0067] The biomass obtained by culturing the Pythium oligandrum M1 microorganism on a solid substrate was mixed with demineralized water and homogenized in a homogenizer vessel (industrial mixer). Homogenization was performed at 3000 to 5000 rpm for 3 minutes. Subsequently, permeate (sucrose) was added to the initial undiluted suspension in an amount corresponding to the resulting concentration of 60% by weight and corresponding to the desired number of oospores. The suspension with permeate (sucrose) was then homogenized in a mixer at 2000 revolutions per minute for 1 minute. The suspension was then stored in sterile stainless steel tanks at a temperature below 8°C.

[0068] It is more advantageous to prepare liquid bioantifungal preparations by combining the homogenization step in demineralized water and the subsequent addition of permeate (sucro...

Embodiment 2

[0075] Liquid bioantifungal preparation for spraying crops with a low weight percentage of biomass

[0076] preparation :

[0077] Pythium oligandrum biomass obtained by liquid culture was mixed with permeate (sucrose) in a vessel of a homogenizer (industrial mixer) and mixed at a concentration to achieve the desired number of oospores and permeate (sucrose) concentration. way of homogenization. Homogenization was performed at 3000 to 5000 rpm for 3 minutes. The suspension was then stored in sterile stainless steel tanks at a temperature below 8°C. The number of resting oospores was determined microscopically using a Sage counting plate counting chamber, and stability was measured using plasmolysis based on microscopic observation of the number of viable oospores according to a publication by Etxeberria et al. [13] in 2011. A preparation is marked as stable if the number of viable oospores does not fall below 90% of the initial value.

[0078] composition:

[0079] ...

Embodiment 3

[0083] Liquid biological antifungal preparations intended for use as seed coatings

[0084] preparation :

[0085] The biomass obtained by culturing the Pythium oligandrum M1 microorganism on a solid substrate was mixed with demineralized water and homogenized in a homogenizer vessel (industrial mixer). Homogenization was performed at 3000 to 5000 rpm for 3 minutes. Subsequently, permeate (sucrose) was added to the initial undiluted suspension in an amount corresponding to the resulting concentration of 60% by weight and corresponding to the desired number of oospores. The suspension with permeate (sucrose) was then homogenized in a mixer for 1 minute.

[0086] It is more beneficial to prepare preparations by combining the steps of homogenization in demineralized water and subsequent addition of permeate (sucrose) into one step, so that the biomass obtained by solid culture is in the container of an industrial homogenizer in the permeate solution (65% sucrose solution) fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com