A control system applied to a cordless iron

A control system and ironing technology, applied in the field of ironing equipment, can solve problems affecting the ironing effect, and achieve the effect of reducing the probability of affecting the ironing effect of clothes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

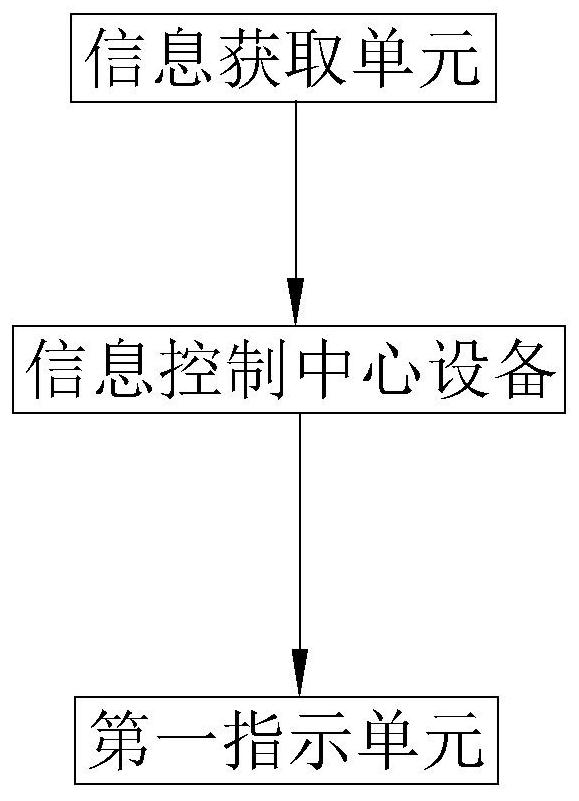

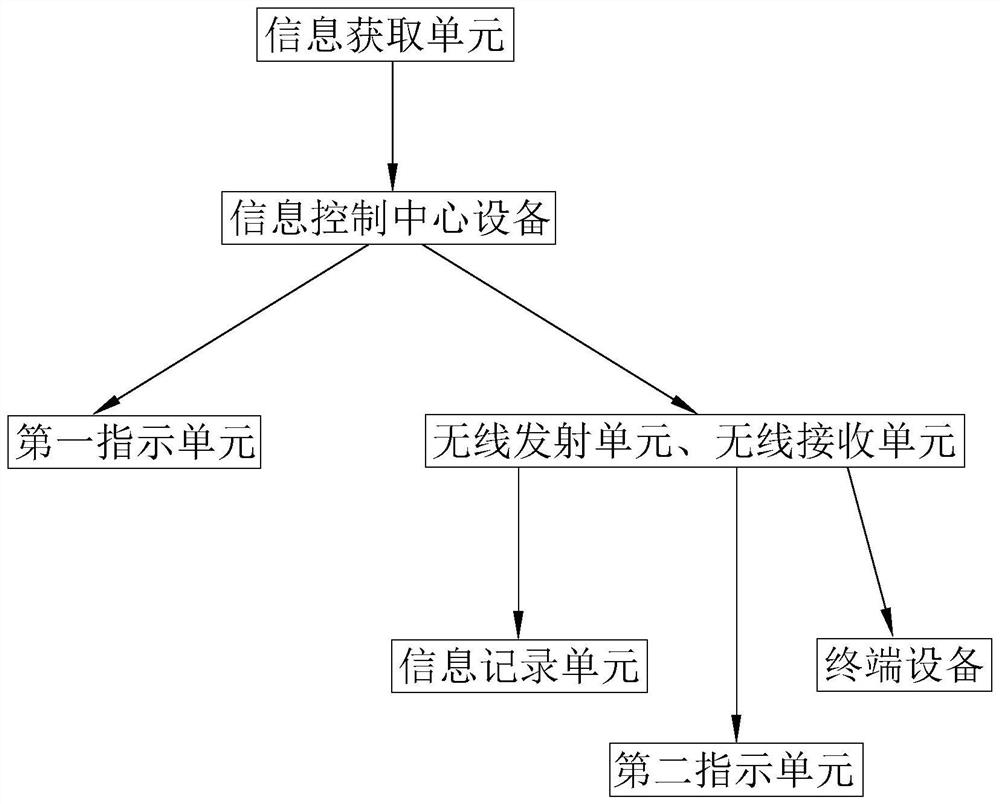

[0050] refer to figure 1 An embodiment of the present invention provides a control system applied to a cordless iron, comprising an ironing body and an iron stand, the cordless iron comprising a heating soleplate equipped with an ironing surface intended to be in contact with fabrics.

[0051] The control system also includes an information acquisition unit arranged on the ironing body for obtaining current state information of the ironing body, a first indication unit arranged on the ironing body and including a first acousto-optic indicator, and a first indication unit arranged on the ironing body The power supply unit for supplying power to the information acquisition unit and the first indication unit; also includes an information control center device arranged on the iron stand and coupled to the wireless receiving unit to obtain the current status information of the ironing body, and the information control center device is set from the preset In the corresponding relati...

Embodiment 2

[0062] The current state information of the ironing body also includes the current working gear information of the ironing body, and the ironing body state information is the working gear information of the ironing body that is not allowed under the corresponding ironing surface temperature information;

[0063] Corresponding to the ironing surface temperature information, the ironing body working gear information that is not allowed is associated with the iron management information;

[0064] Under the current temperature information of the ironing surface, when the current working gear information of the ironing body matches the status information of the ironing body, the second sound is controlled according to the current iron management information corresponding to the current working gear information of the ironing body. The working status of the light indicator.

[0065] Here, the information on the working gear of the ironing body is also the working gear of the ironing...

Embodiment 3

[0067] The current status information of the ironing body also includes the current continuous working time information of the ironing body, and the status information of the ironing body is the continuous working time information of the ironing body that is not allowed under the corresponding ironing surface temperature information;

[0068] The continuous working time information of the ironing body that is not allowed under the ironing surface temperature information is associated with the iron management information;

[0069] Under the current temperature information of the ironing surface, when the current continuous working time information of the ironing body matches the status information of the ironing body, the second sound is controlled according to the current iron management information corresponding to the current continuous working time information of the ironing body. The working status of the light indicator.

[0070] Here, the current continuous working time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com