Structure for stabilizing cabin units

A cabin unit and unit structure technology, which is applied in the field of ship cabins, can solve the problems of not being able to effectively achieve the shock absorption effect and affect the life and work of the staff on board, and achieve the effect of improving bearing comfort, reducing perception, and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below according to the attached Figure 1 to Figure 8 , give a preferred embodiment of the present invention, and give a detailed description, so that the functions and characteristics of the present invention can be better understood.

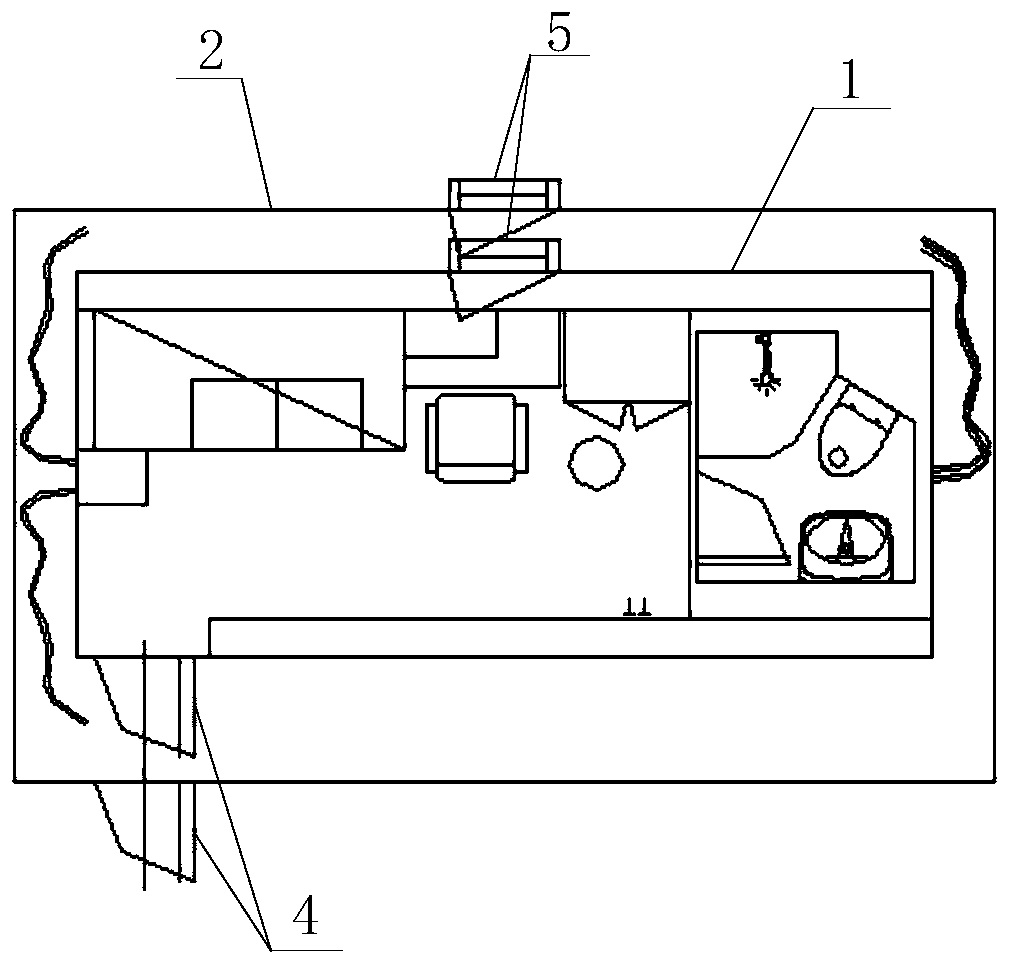

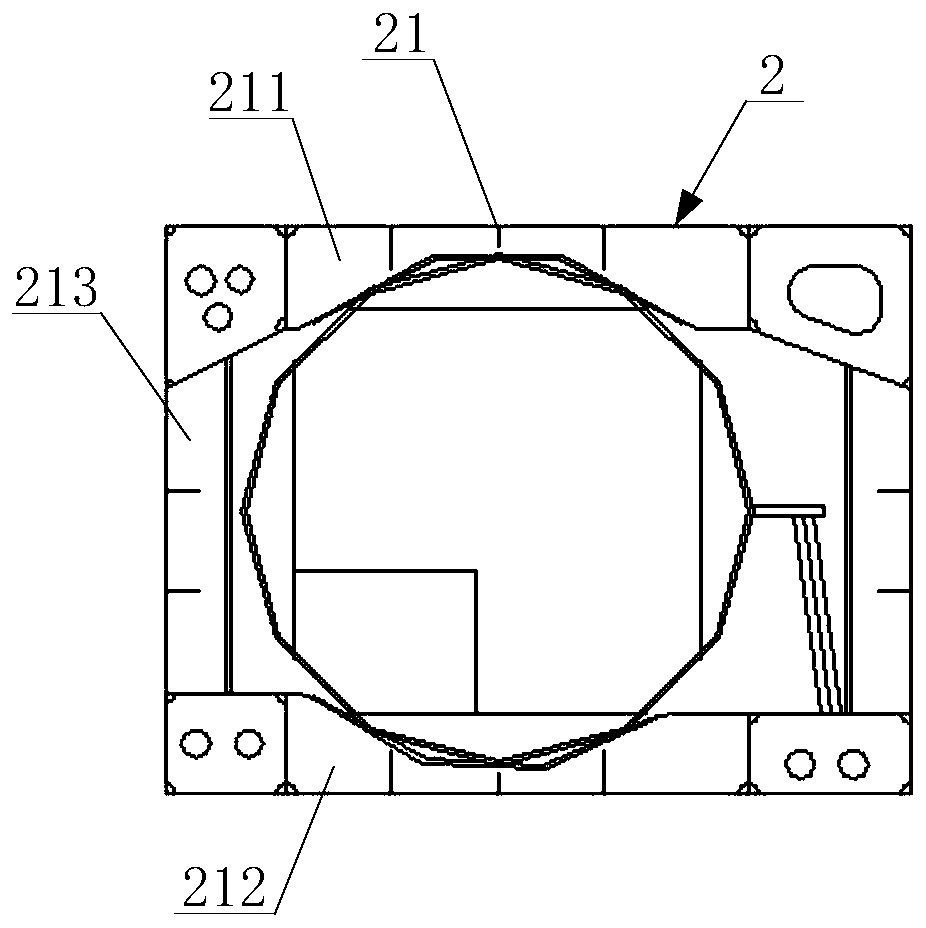

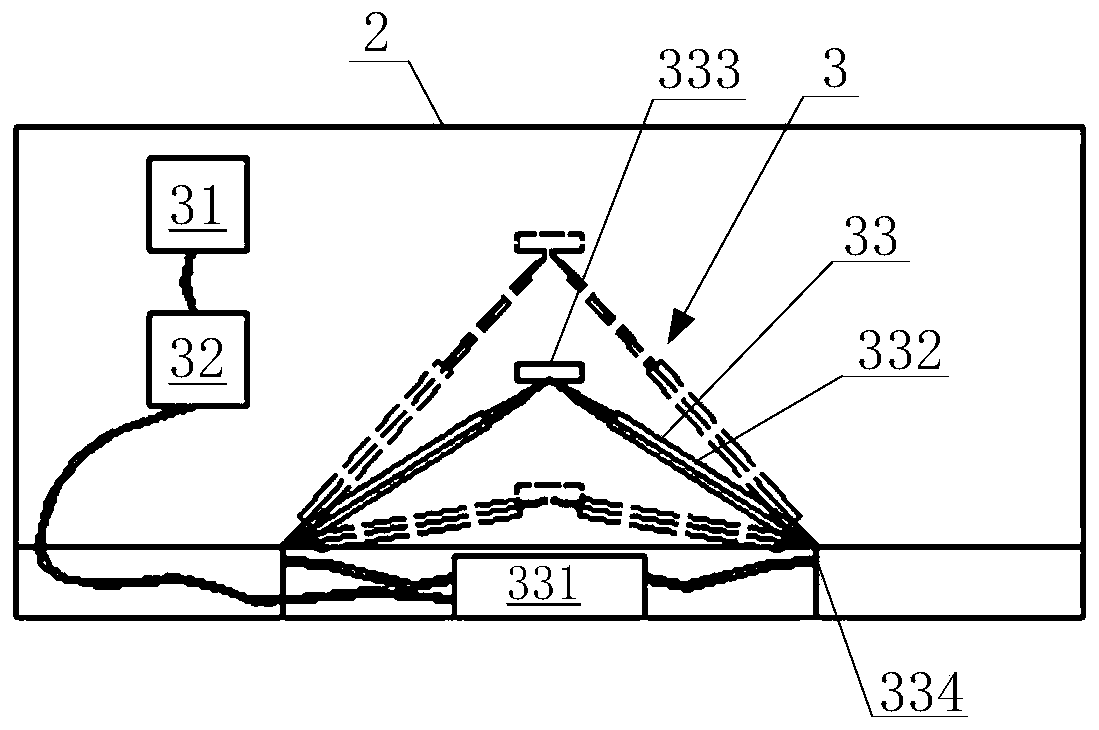

[0025] see Figure 1 ~ Figure 3 , an anti-rolling cabin unit structure according to an embodiment of the present invention, comprising an inner cabin unit 1, an outer cabin unit 2 and a cabin anti-rolling mechanism 3; the inner cabin unit 1 is cylindrical, and the outer cabin unit 2 A cabin anti-rolling mechanism 21 is formed on the inner wall, and the inner cabin unit 1 is installed in the outer cabin unit 2 so as to freely rotate around the axial direction through the cabin anti-rolling mechanism 21; the cabin anti-rolling mechanism 3 is connected to the outer cabin unit 2 and the inner cabin unit 2. Layer cabin unit 1 between.

[0026] The inner cabin unit 1 is mounted in the outer cabin unit 2 in a manner that can freely rotate ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com