Intelligent manufacturing teaching training platform with material block conveying device

A conveying device and intelligent manufacturing technology, which is applied in the field of ore mining, can solve the problems of increasing the work intensity of workers, high power of two-way belts, unfavorable ore transportation, etc., so as to avoid complicated steps, reduce work intensity, and change the conveying time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

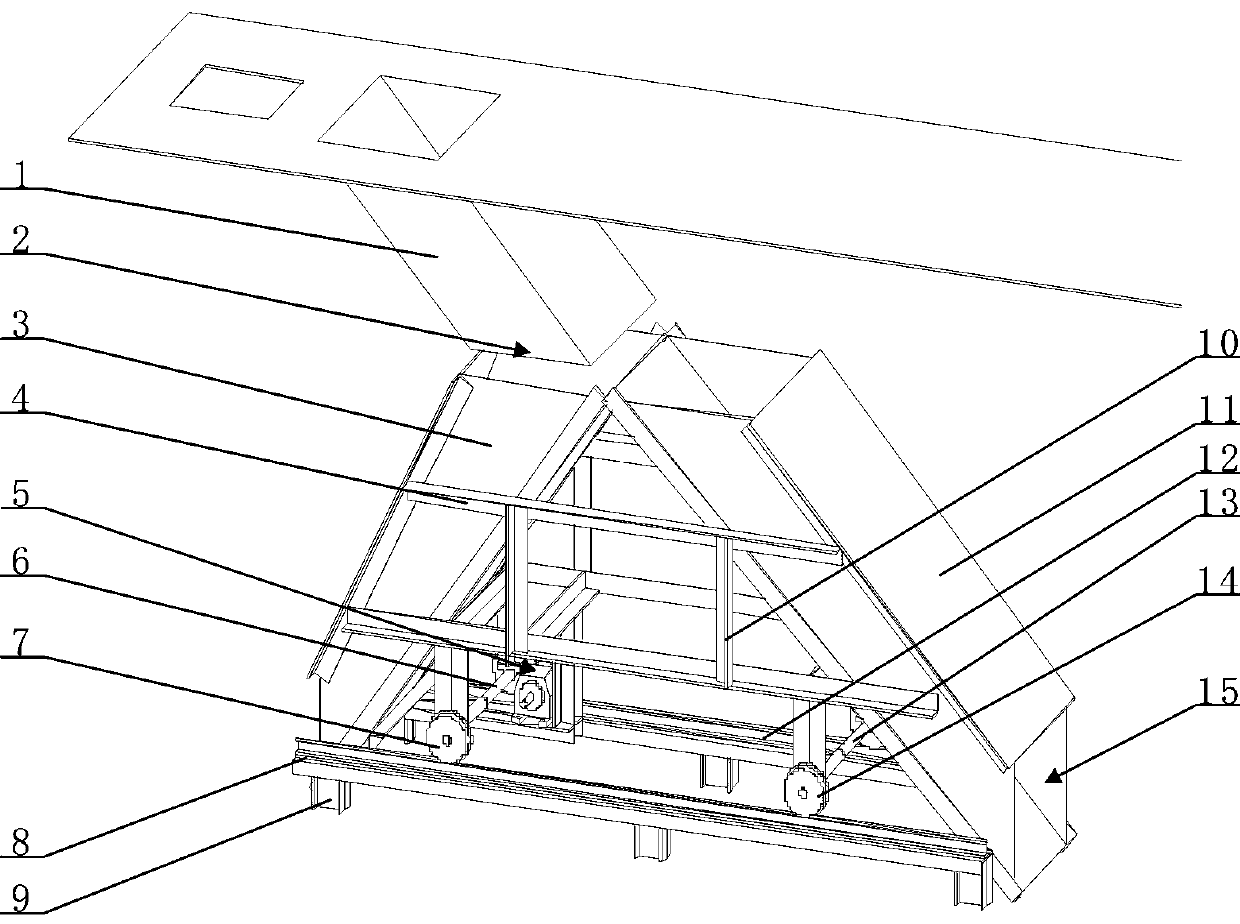

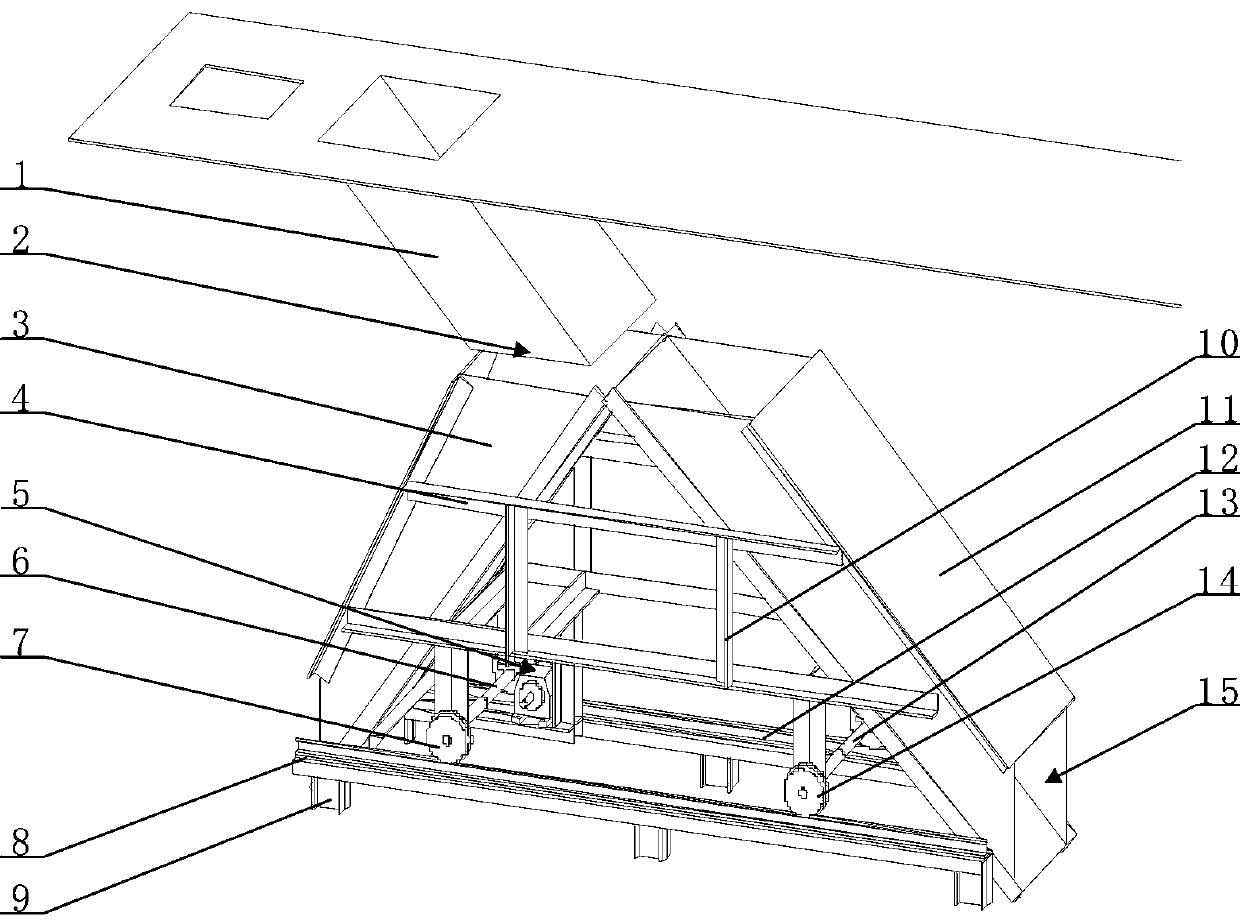

[0029] Embodiment 1, the intelligent manufacturing teaching and training platform with a material block conveying device, when in use, turn on the motor, align the feeding port 2 at the bottom of the fixed chute 1 with the opening at the top of the left chute 3, and then When the ore enters from the fixed chute 1 to the left chute 3 for transportation, and finally passes out from the discharge port 15 at the bottom of the left chute 3, when it is necessary to change the ore transportation direction, start the motor so that the drive system 5 controls the drive shaft 6 and the drive wheel 7 rotates, the driving shaft 6 and the driving wheel 7 drive the driven shaft 13 and the driven wheel 14 to move on the first track 8 and the second track 12, and the movement of the driving wheel 7 and the driven wheel 14 drives the left chute 3 and the right chute 11. The horizontal support 4 and the vertical support 10 move as a whole, and limit switches are provided on the first track 8 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com