Polycarbonate resin composition

A technology of polycarbonate resin and composition, which is applied in the fields of instruments, organic chemistry, optics, etc., and can solve problems such as ignorance of polycarbonate resin composition, large amount of gas generation, large compounding volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

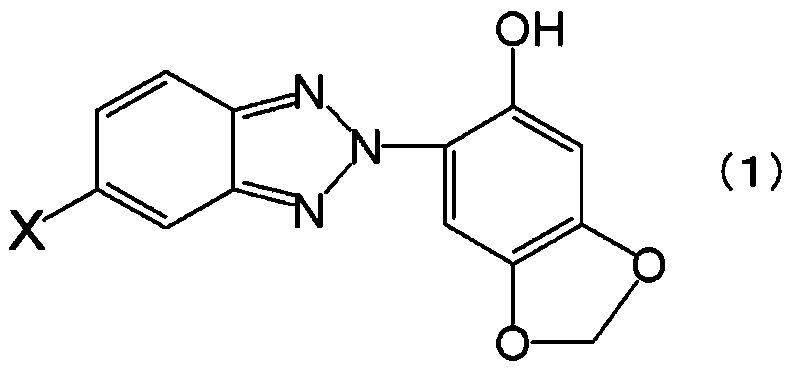

[0140] The following are preferred examples of compounds represented by the general formula (2) and having a maximum absorption wavelength of 360 nm or more and less than 375 nm: 6-(2H-benzotriazol-2-yl)benzo[1,3]dioxa Cyclopenten-5-ol, 6-(5-n-heptylcarbonyloxyethyl-2H-benzotriazol-2-yl)benzo[1,3]dioxol-5-ol , 6-(5-isoheptylcarbonyloxyethyl-2H-benzotriazol-2-yl)benzo[1,3]dioxol-5-ol, 6-(5-methyl Base-2H-benzotriazol-2-yl)benzo[1,3]dioxol-5-ol, 6-(5-methoxy-2H-benzotriazol-2-yl ) benzo[1,3]dioxol-5-ol, 6-(5-hydroxy-2H-benzotriazol-2-yl)benzo[1,3]dioxol -5-ol, 6-(5-octyloxy-2H-benzotriazol-2-yl)benzo[1,3]dioxol-5-ol, 6-(5-carboxy- 2H-benzotriazol-2-yl)benzo[1,3]dioxol-5-ol, 6-(5-hydroxyethyl-2H-benzotriazol-2-yl)benzene And[1,3]dioxol-5-ol, and 6-(5-methylcarbonyloxyethyl-2H-benzotriazol-2-yl)benzo[1,3]di Oxol-5-ol.

[0141] Among the foregoing, 6-(2H-benzotriazol-2-yl)benzo[1,3]dioxol-5-ol, 6-(5-n-heptylcarbonyloxyethyl- 2H-Benzotriazol-2-yl)benzo[1,3]dioxol-5-ol, and 6-(...

specific example

[0152] The ultraviolet absorber (B3) is more preferably a benzotriazole-based ultraviolet absorber and particularly preferably a benzotriazole-based compound not having a sesamol group. The following are preferred specific examples of such benzotriazole compounds: 2-(2-hydroxy-5-tert-octylphenyl)-2H-benzotriazole, 2-(3-tert-butyl-2-hydroxy -5-methylphenyl)-5-chloro-2H-benzotriazole, 2-[5-chloro(2H)-benzotriazol-2-yl]-4-methyl-6-(tert-butyl base) phenol, 2,4-di-tert-butyl-6-(5-chlorobenzotriazol-2-yl)phenol, (2-[5-chloro(2H)-benzotriazol-2-yl ]-4,6-di(tert-amyl)phenol), 3-[3-tert-butyl-5-(5-chloro-2H-benzotriazol-2-yl)-4-hydroxyphenyl]octyl Propionate, 2-(3-tert-butyl-5-methyl-2-hydroxyphenyl)-5-chlorobenzotriazole, 2-(2H-benzotriazol-2-yl)- 6-dodecyl-4-methylphenol, 2-(2H-benzotriazol-2-yl)-p-cresol, 2-[(2H)-benzotriazol-2-yl]-4 ,6-bis(1-methyl-1-phenethyl)phenol.

[0153] The preferred content of the ultraviolet absorber (B3) is 0.01 to 0.02 parts by mass relative to 100 pa...

Embodiment 1 to 22、 comparative example 1 to 9

[0227] [Manufacture of resin composition pellets]

[0228] The components given in Table 1 were blended in the ratios (parts by mass) indicated in Tables 2 to 4 and mixed with a tumbler mixer for 20 minutes. Then melt kneading was carried out by a vented single-screw extruder ("VS-40" of Tanabe Plastics Machinery Co., Ltd.) having a screw diameter of 40 mm at a barrel temperature of 280° C., and the polymer was obtained by strand cutting. Pellets of carbonate resin composition.

[0229] [Measurement of transmittance and absorbance]

[0230] The obtained pellets were dried at 120° C. for 5 hours using a hot air circulation dryer, followed by molding at a resin temperature of 280° C., a mold temperature of 80° C., and 30 seconds by an injection molding machine ("SE50DUZ" of Sumitomo Heavy Industries, Ltd.) Under cyclic conditions, a stepped flat-shaped test piece with a width of 50 mm, a length of 90 mm, and three thicknesses of 1 mm, 2 mm, and 3 mm was formed.

[0231] The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com