Special tool for 10KV circuit live-wire work robot drainage wire connecting work

A technology for live work and special tools, which is applied in the field of special end tools for live work robots, and can solve problems such as electric shock risk, high safety risk, and lack of drainage wire cutting function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] The structures involved in the present invention or the technical terms used are further described below. These descriptions are only used as examples to illustrate how the present invention is implemented, and do not constitute any limitation to the present invention.

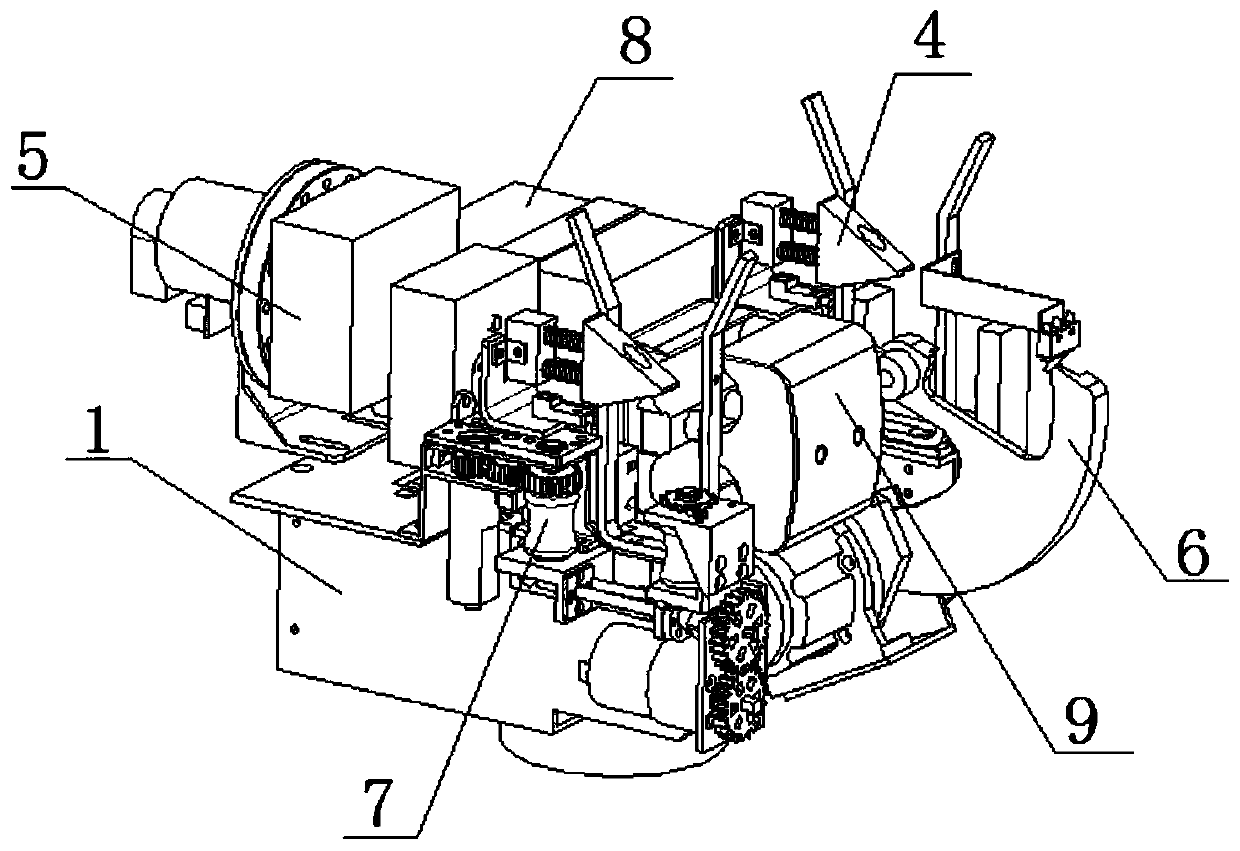

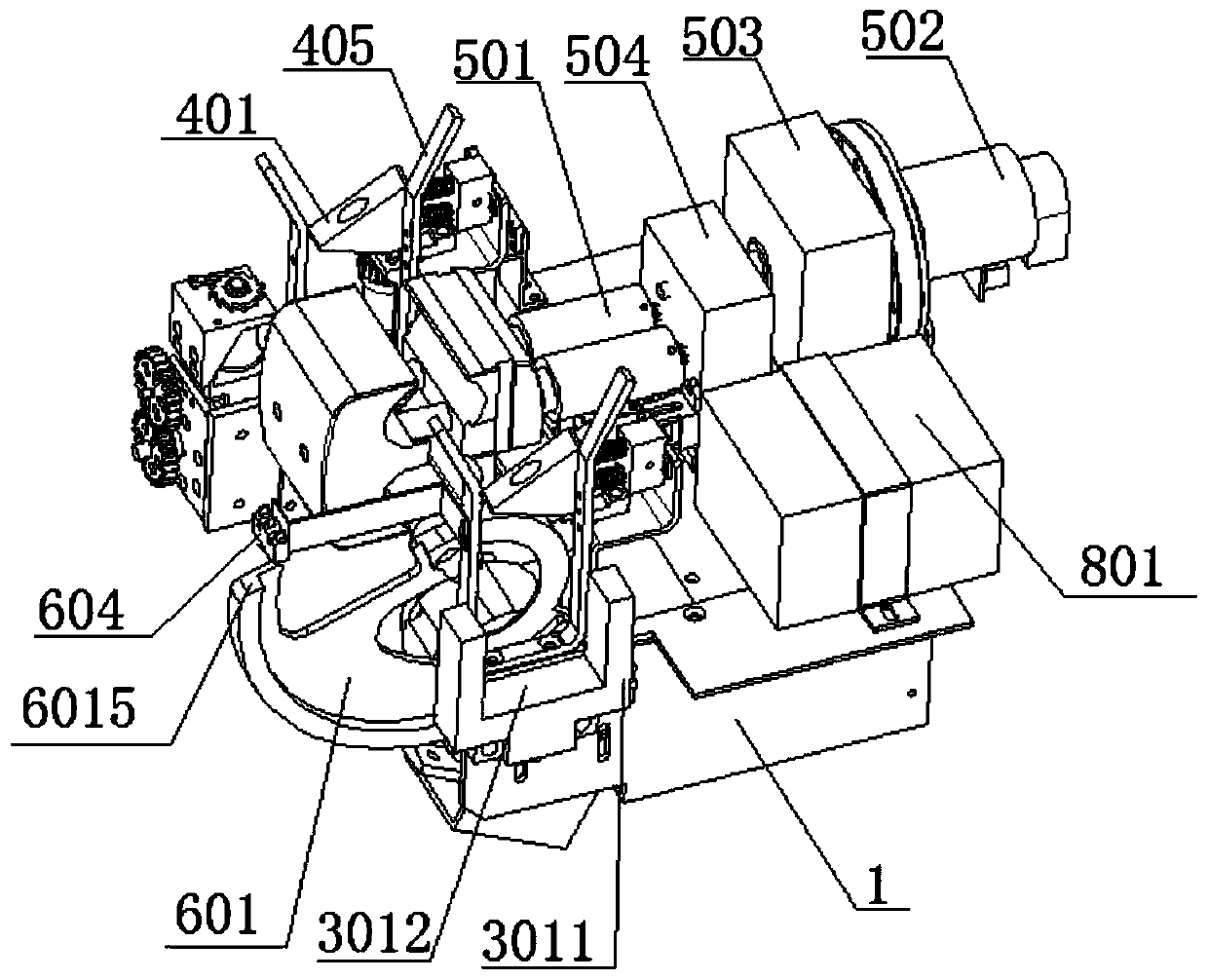

[0097] Special tools for 10KV line live working robots connecting drain wires, including wire clamp clamping mechanism, main wire mounting mechanism, nut tightening mechanism, drain wire clamping and tensioning mechanism, drain wire shearing mechanism and power supply mechanism, see Figure 1-3 , can realize puncture wire clip grasping and clamping, drainage wire threading and clamping, main wire mounting, nut tightening, drainage wire tensioning, redundant drainage wire cutting, unlocking and releasing and other autonomous functions.

[0098] Piercing clip

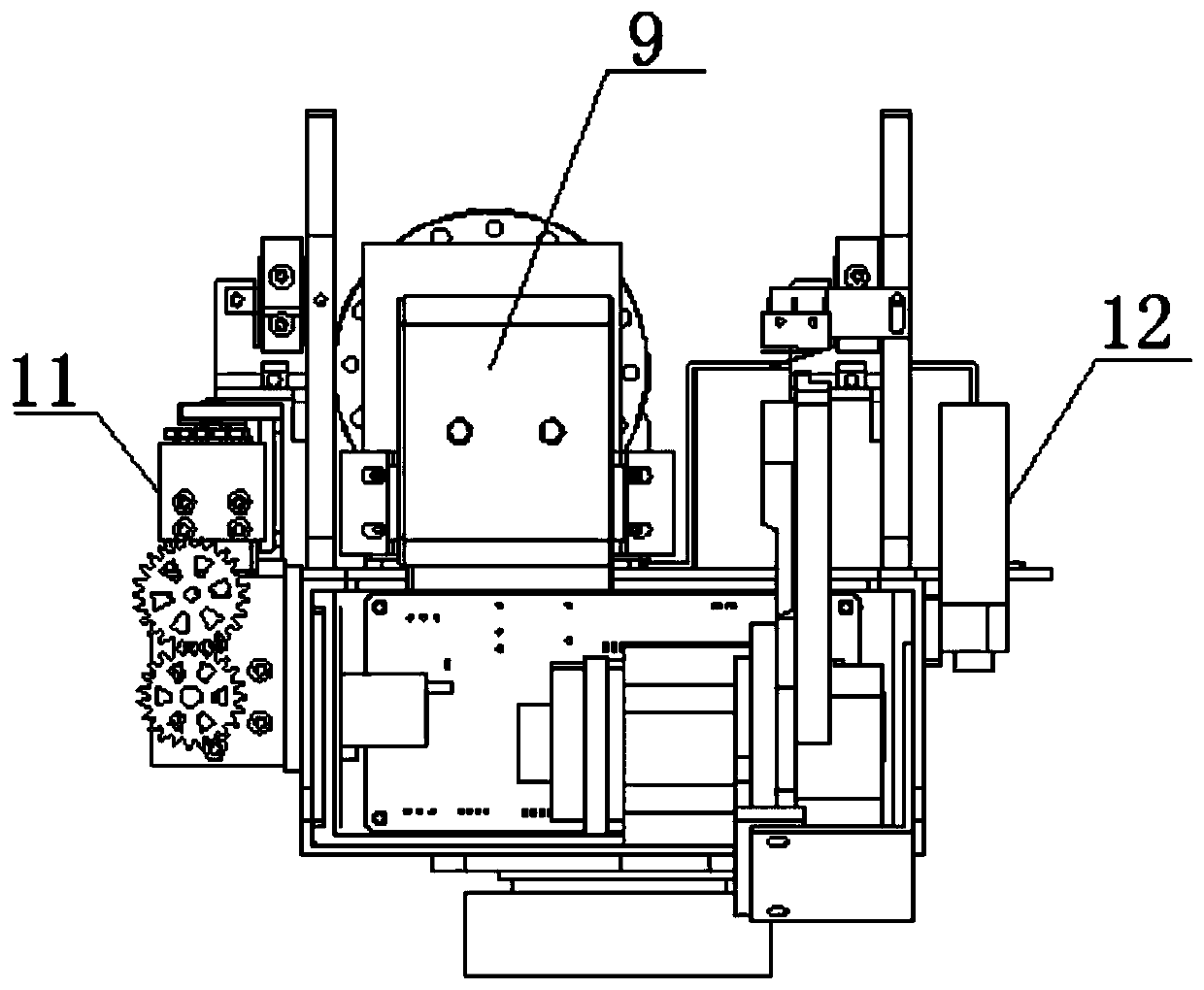

[0099] Puncture wire clamp 9 is prior art, as Figure 4 As shown, it includes an insulating housing, a puncture blade, a screw 93 and a torque n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com