Steel structure building stair capable of switching feeding surfaces

A technology for steel structures and stairs, applied in stairs, buildings, and ladder-like structures, etc., can solve problems such as troublesome operation, greater energy consumption, and trouble, and achieve the effects of stable structure, simple operation, and labor-saving switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

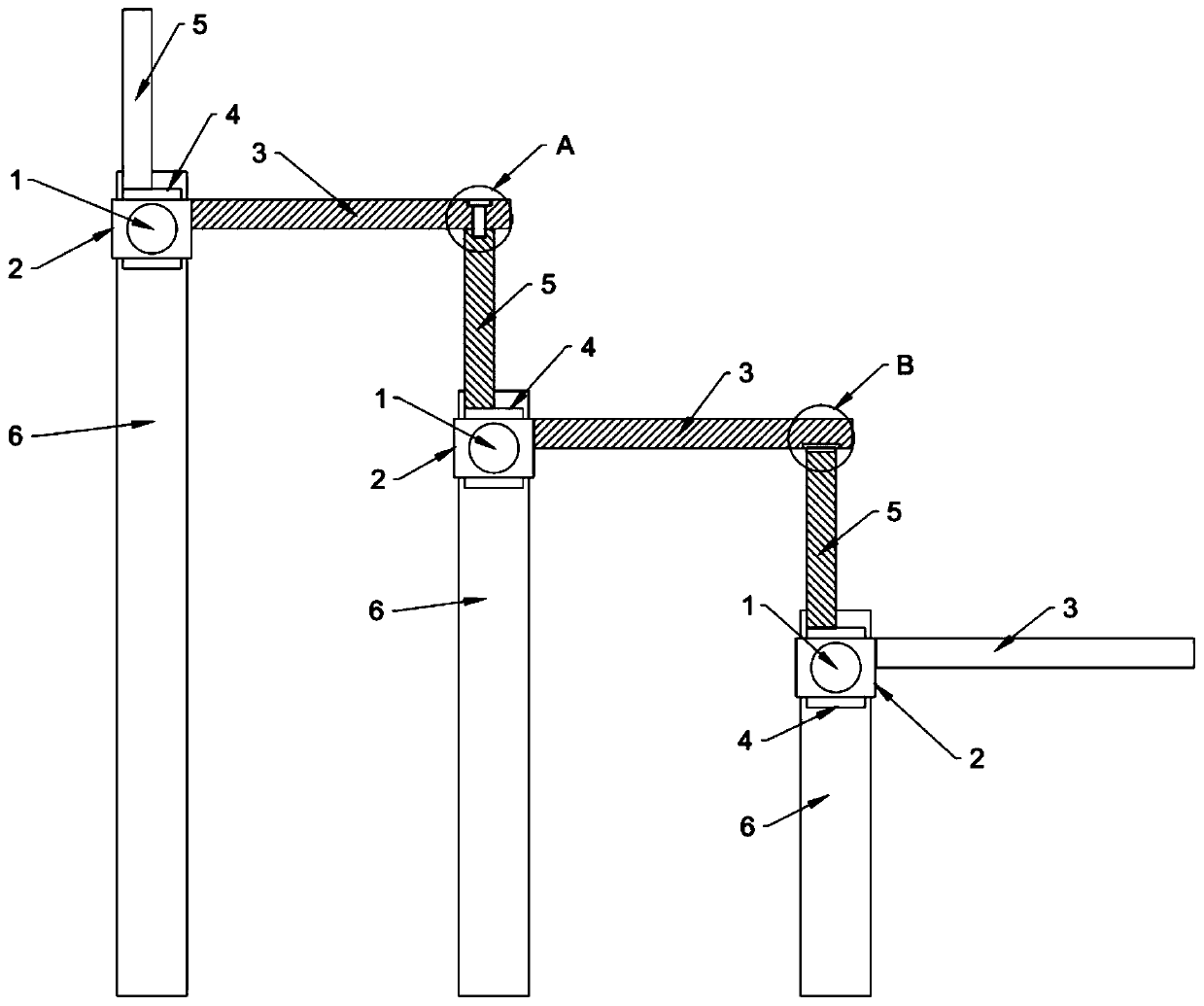

Embodiment 1

[0039] Embodiment 1: The separation structure includes an opening groove 10, a through hole 11 and a fixing groove 12. An opening groove 10 is formed on the upper surface of the end of the horizontal stair plate 3 away from the rotating shaft 1, and the side of the opening groove 10 close to the vertical stair plate 5 is connected with a through setting. The through hole 11 of the vertical stair plate 5 is provided with a fixing groove 12 corresponding to the through hole 11, and a fastening screw 13 is movably inserted in the opening groove 10, the through hole 11 and the fixing groove 12. The hole 11 will be aligned with the fixing groove 12, and then the fastening screw 13 is inserted from the opening groove 10 and enters the fixing groove 12 to realize the mutual fixing between the vertical stair board 5 and the horizontal stair board 3, without Relative movement takes place again, between locked, when needing to switch to inclined-plane type, pull out fastening screw 13 an...

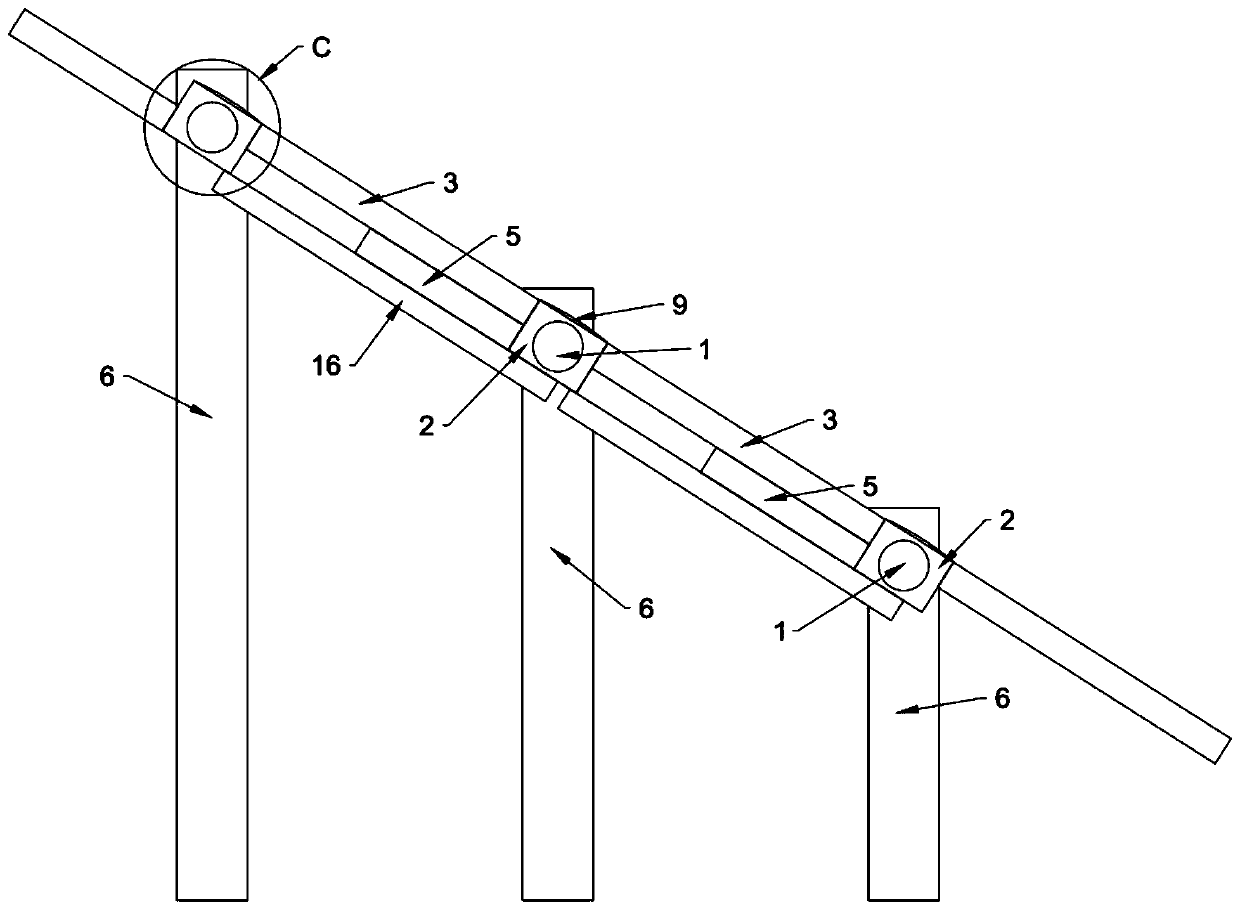

Embodiment 2

[0040] Embodiment 2: The separation structure includes a magnetic block 14 and an adsorption iron block 15. The lower surface of the horizontal stair plate 3 away from the rotating shaft 1 is fixedly embedded with a magnetic block 14. The magnetic block 14 is detachably connected with an adsorption iron block 15, and the adsorption iron block 15 is fixedly embedded in the vertical stair slab 5. After switching to the step type, the magnetic block 14 will be attracted to each other with the adsorption iron block 15 to achieve a relatively fixed effect. The vertical stair slab 5 and the horizontal stair slab 3 Locked to prevent relative movement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com