Full-blade-tip impeller type double-drive efficient wind-driven generator

A wind turbine and impeller technology, which is applied to wind turbines, wind turbine combinations, and wind turbines that are consistent with the wind direction, etc., can solve problems such as difficulty in adjusting the generator load, poor adaptability to wind changes, and excessively long transmission shaft connections. , to achieve the effect of adjusting engine load, improving efficiency and shortening the length of the main shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

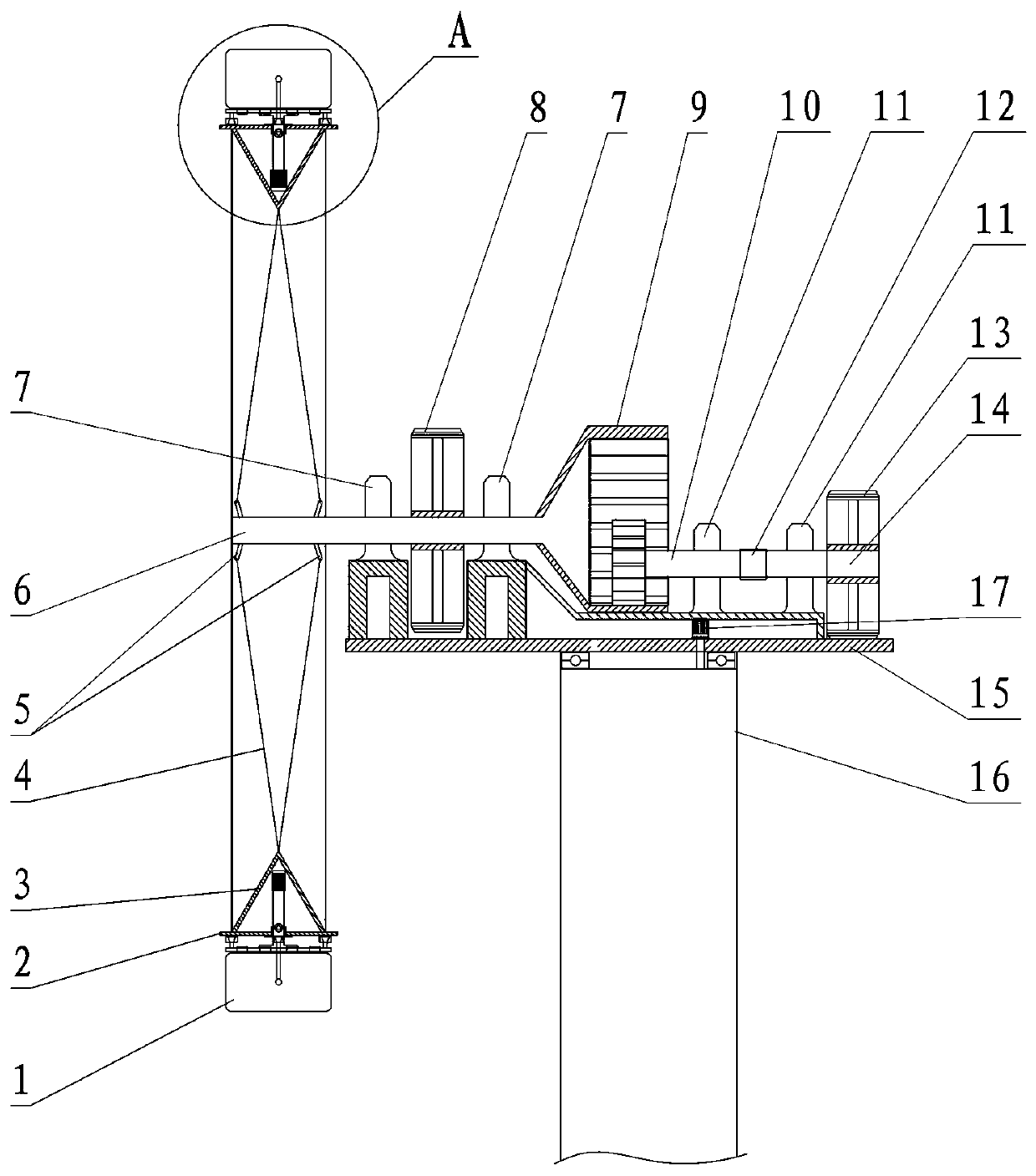

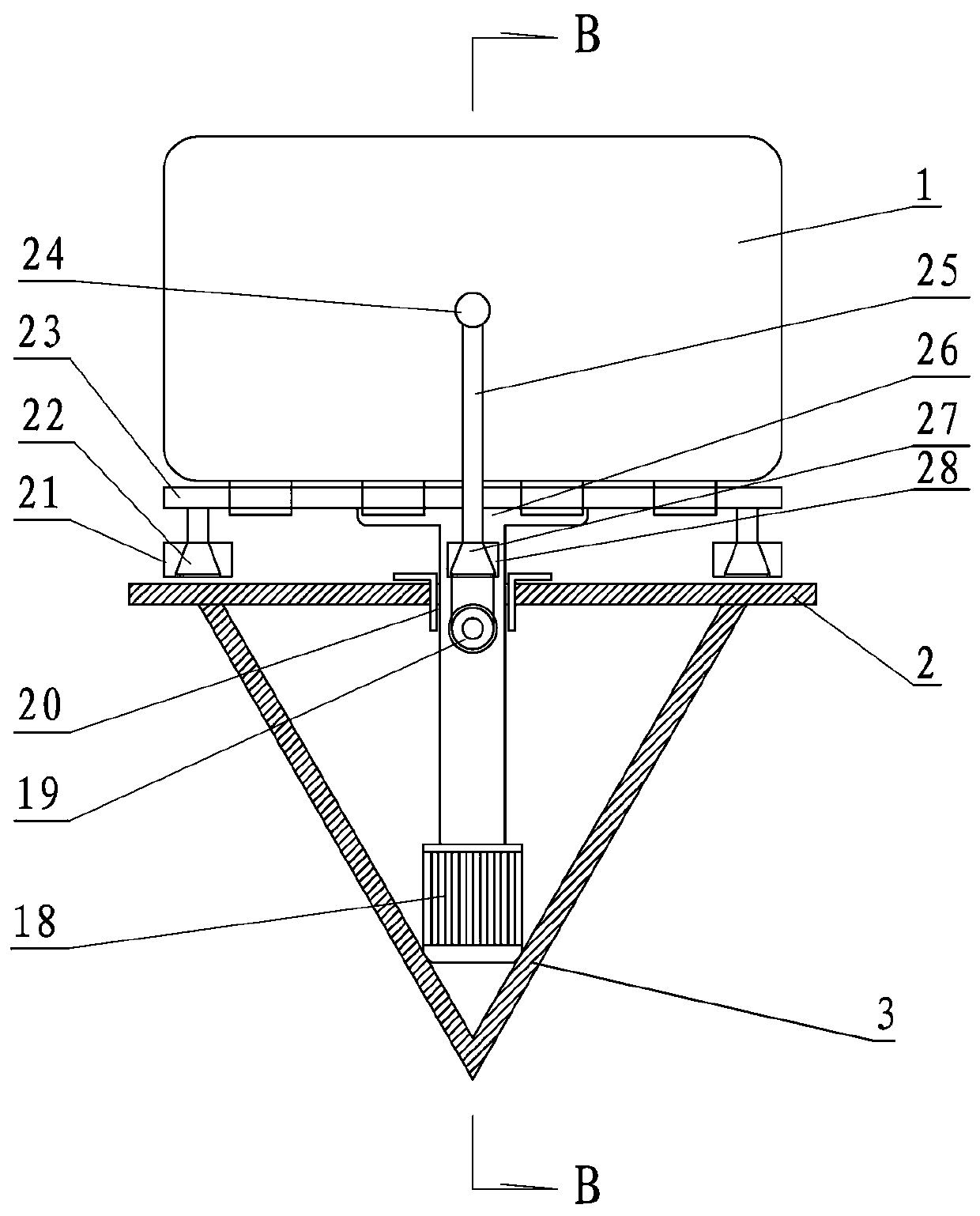

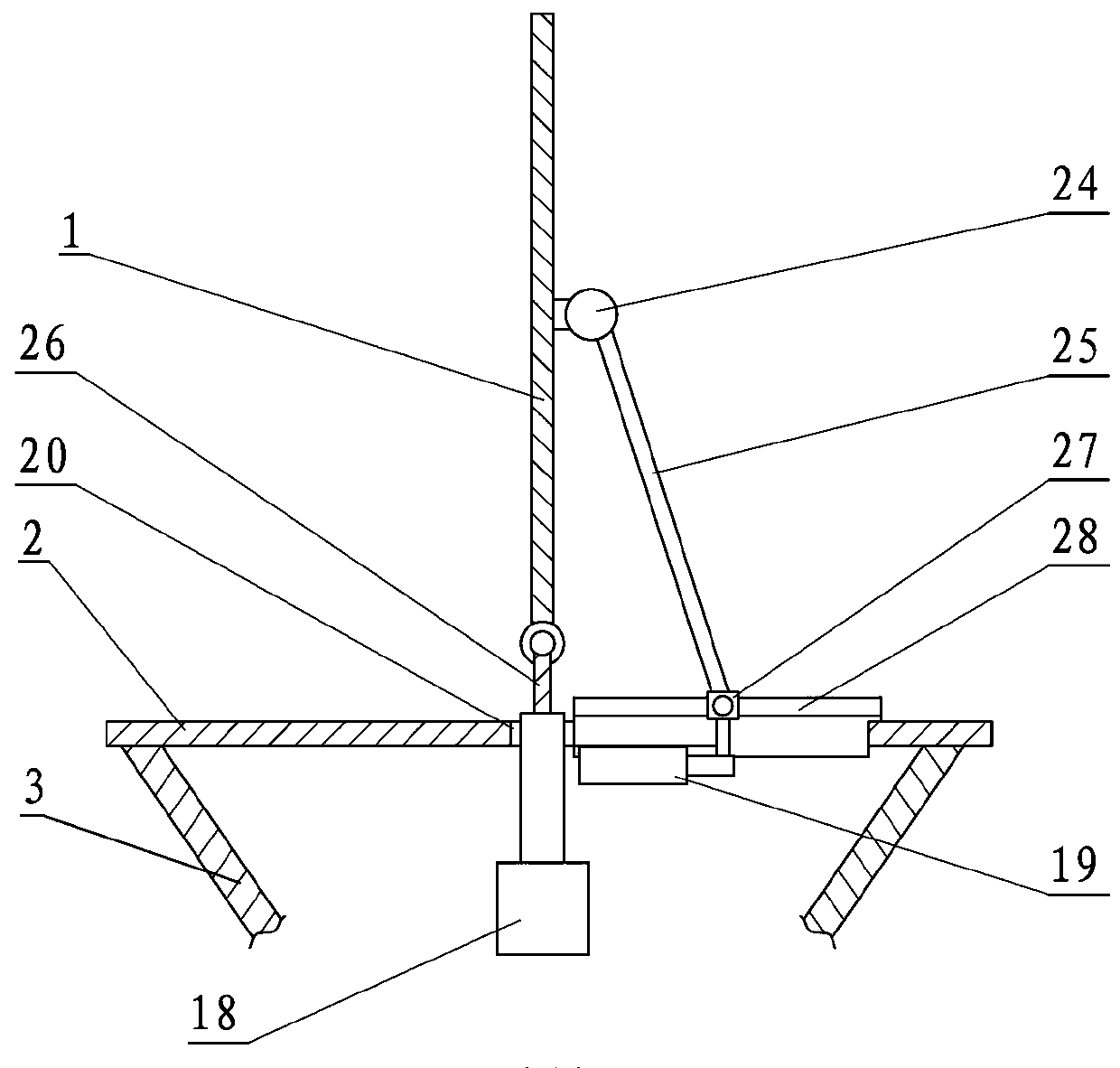

[0017] according to Figure 1~4 Describe in detail the specific structure of the present invention, which is an improvement based on the applicant's publication number CN103147926B "Full Blade Tip Wind Power Generator", examples are Figures 1 to 2 As shown, a full-tip impeller-type double-drive high-efficiency wind power generator includes: a tower 16 at the bottom that is used to connect the base on the ground or above water to support and connect, through the yaw motor 17, the yaw The gear set and the bearing are arranged on the yaw platform 15 which can adjust the direction on the tower, and the full-tip impeller and generator assembled on the yaw platform through the main shaft 6 and the bearing assembly.

[0018] Wherein, the inner side of the rim 3 of the full-tip impeller is fixedly connected to the double disc-shaped flange 5 at the front end of the main shaft 6 through the stay cable 4, and the disc-shaped openings of the double-disc flange 5 are respectively facing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com