Conveyor bridges and conveying equipment with tunnel conveyors and conveyor bridges

A technology for conveying equipment and conveyors, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as disassembly troubles, and achieve the effect of simplifying installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

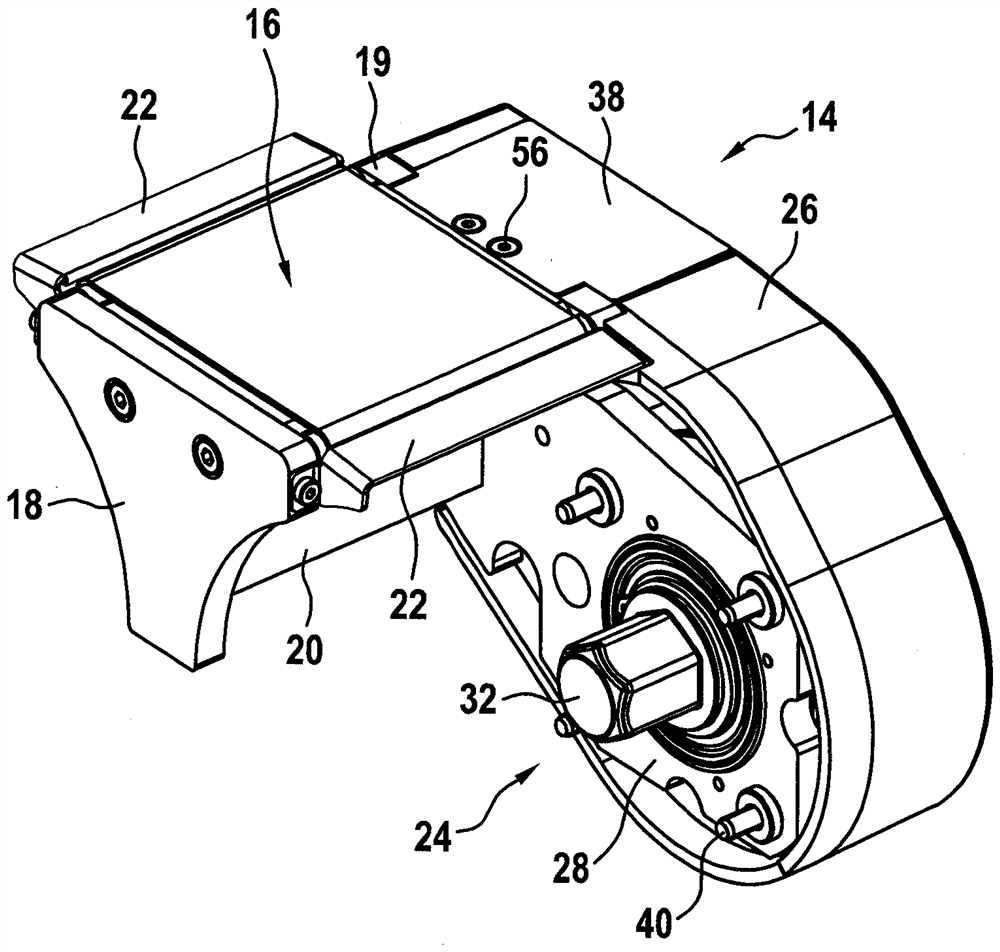

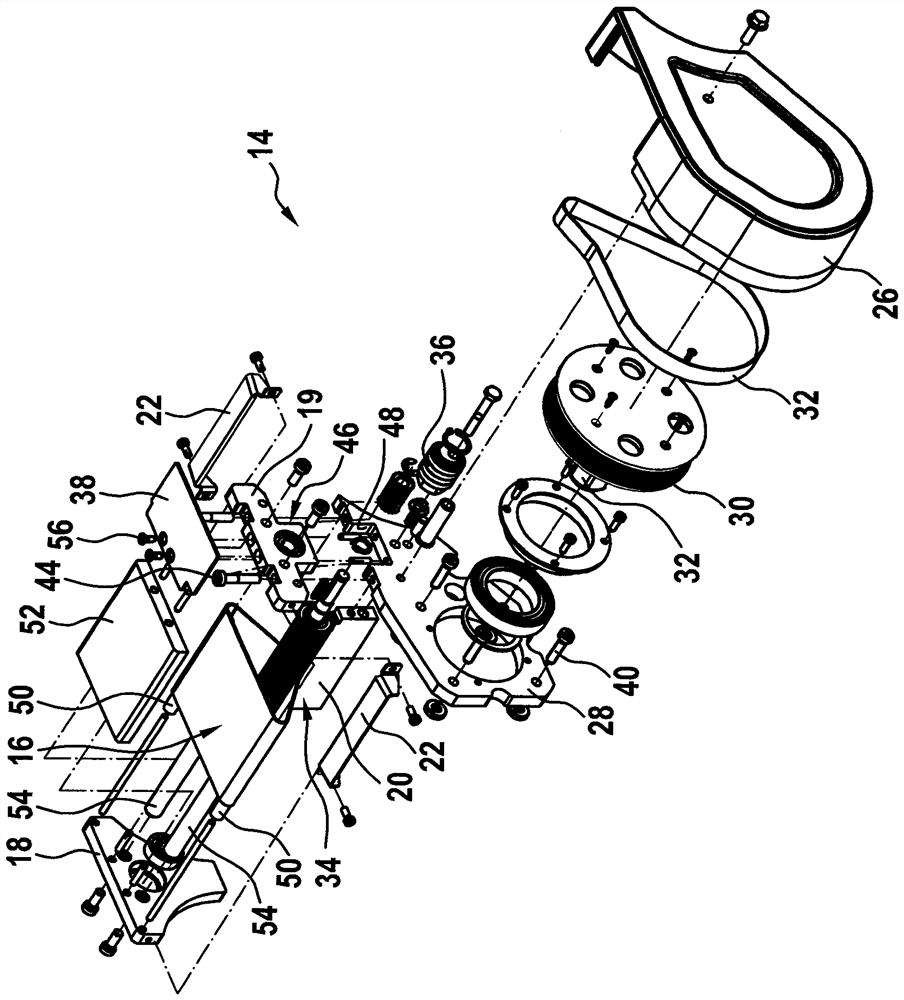

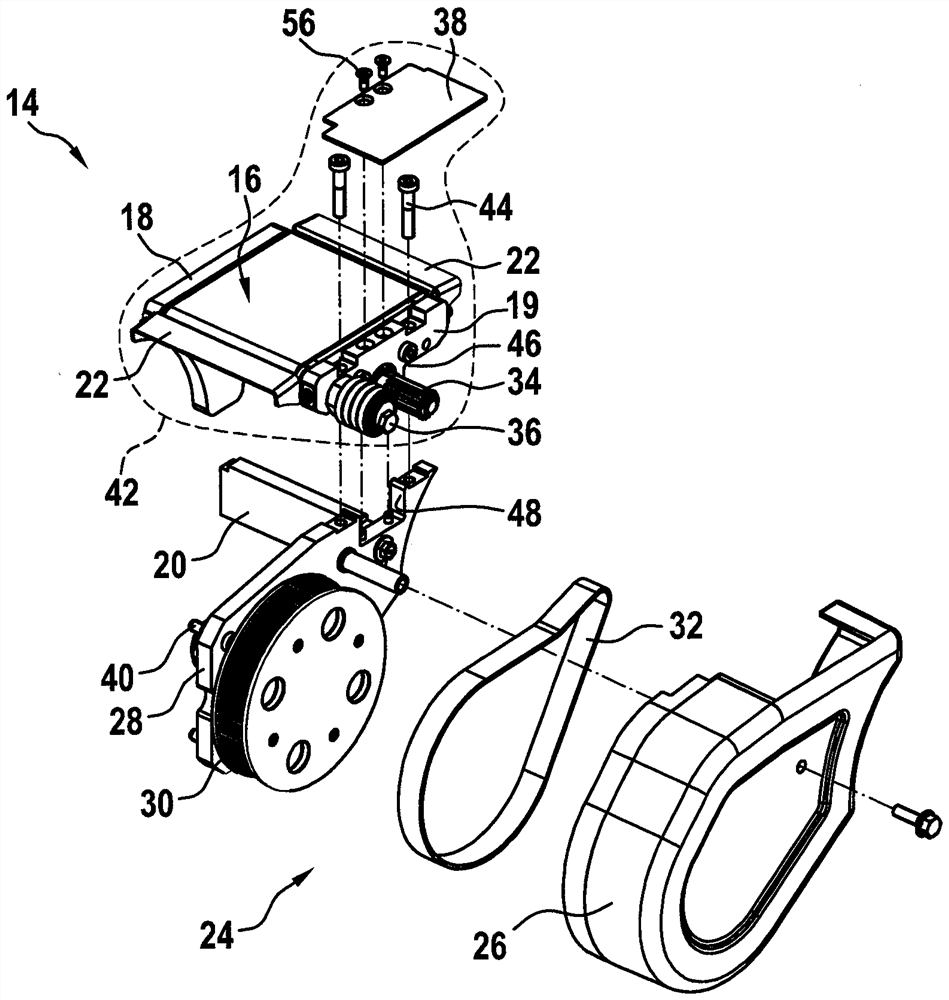

[0041] according to figure 1 , the conveying device 1 has a road conveyor 2 configured as a chain conveyor. exist figure 1 Only one chain conveyor 2 is shown, which has conveying means 4 designed as chains, which continuously rotate on a frame 6 of the chain conveyor 2 . The frame 6 is supported on a number of columns 8 at the bottom. the chain 4 in its figure 1 The upper side shown in is used for conveying a conveying material (not shown). The conveyed material rests on the chain 4 during operation. The chain 4 is designed in such a way that it can be bent not only in a direction normal to the conveying plane but also in a direction parallel to the conveying plane. The first-mentioned flexibility is used in the region of the end section 10 of the chain conveyor 2 to deflect the chain 4 and to guide it back, and the last-mentioned flexibility is The reversing of the road conveyor 2 can be realized, for example, in the region of the bend 12 .

[0042] The conveying devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com