Manufacturing method of absorptive object

A manufacturing method and absorbent technology, which is applied in the manufacture of absorbent articles and the field of new boxer menstrual pants, can solve problems such as inability to process, and achieve the effects of high production efficiency, rich selection, and reasonable manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

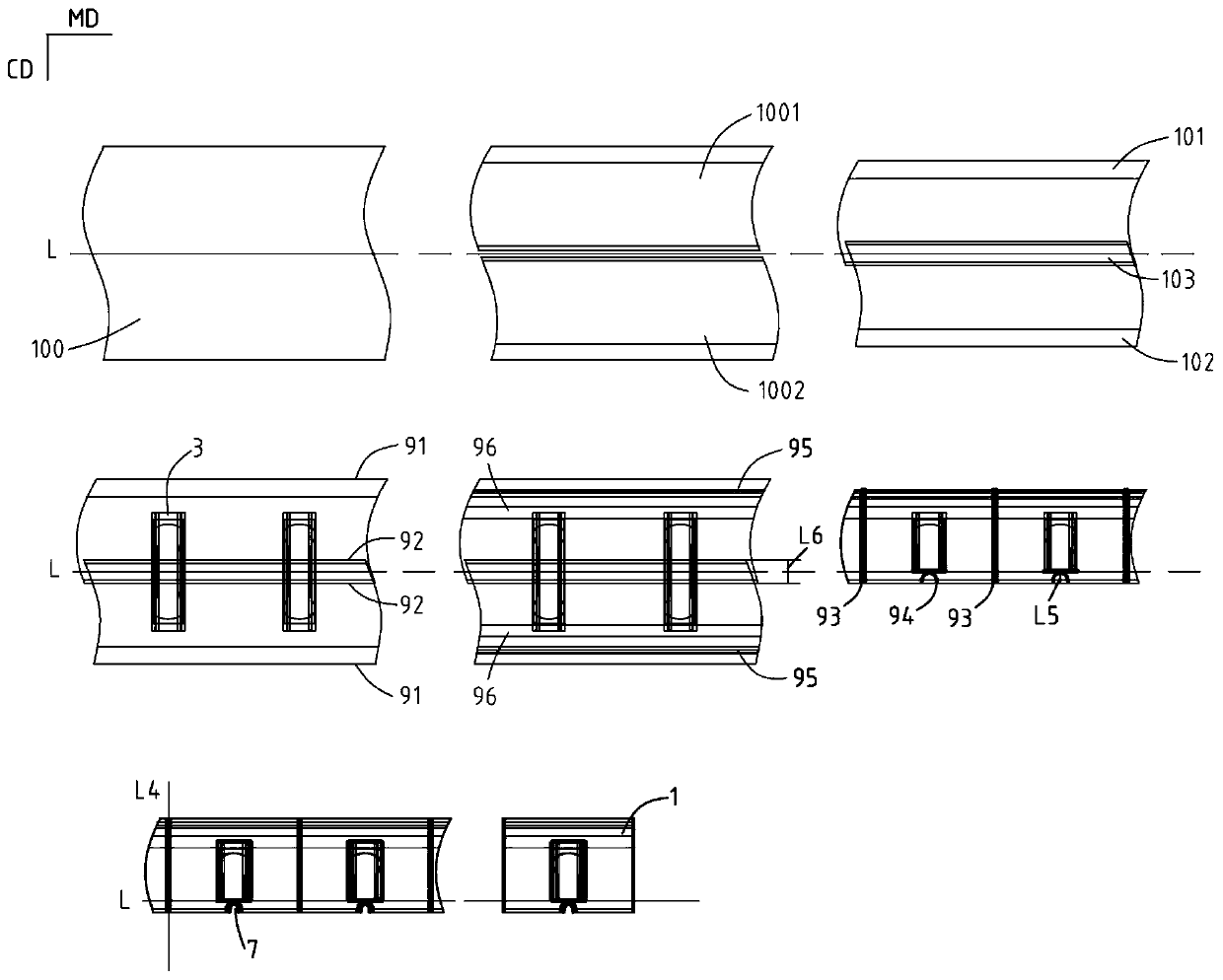

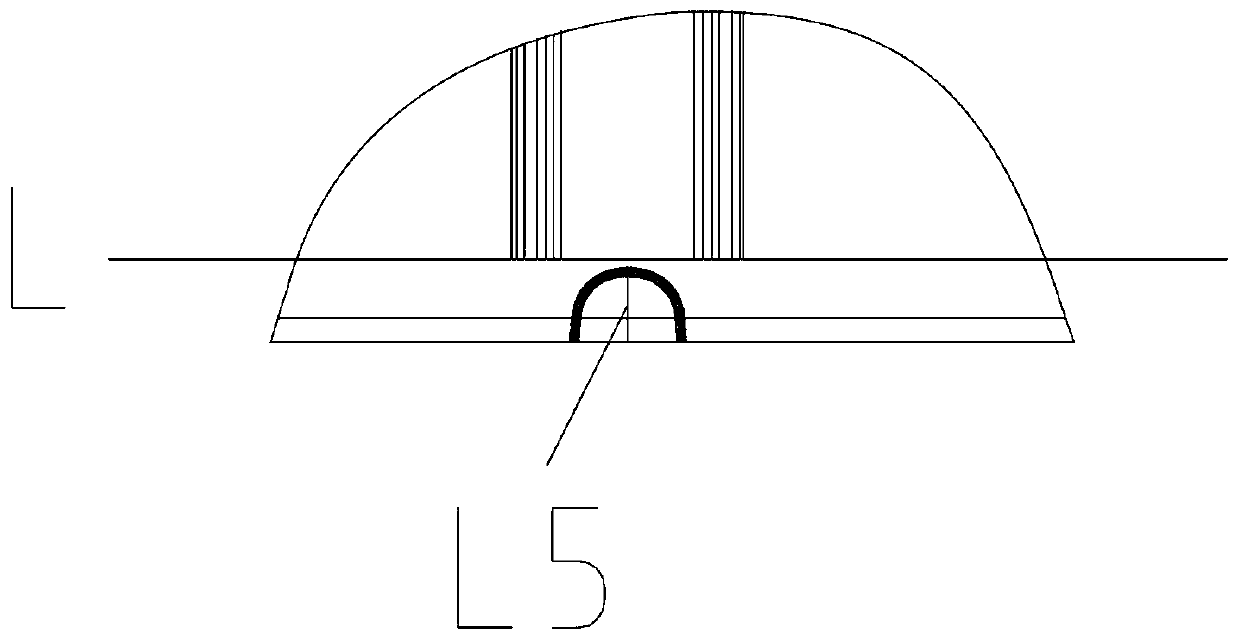

[0039] see Figures 2 to 3 , a method for manufacturing an absorbent article, comprising the following steps:

[0040] S1. Overlapping process, two pieces of the first elastic sheet 101 and the second elastic sheet 102 having elasticity at least in the flow direction MD approach each other in the width direction CD perpendicular to the flow direction MD until partially overlapped, An overlapping region 103 is formed.

[0041] The following steps are performed before the stacking step: a splitting step, in which the conveyed sheet 100 is cut along the process centerline L to form a first sheet 1001 and a second sheet 1002 . In the step of imparting elasticity, an elastic member is applied on the side of the first sheet 1001 and the second sheet 1002 close to the wearer along the process direction MD to form the first elastic sheet 101 and the second elastic sheet 102 . After the elastic member is arranged, it also includes: a wrapping process, which wraps the two side edges of ...

Embodiment 2

[0063] Please also refer to Figures 9 to 12 , an absorbent article 1' having a longitudinal direction y' and a transverse direction x', comprising: an outer covering layer 2' and an inner absorbent structure 3' arranged inside the outer covering layer 2'.

[0064] Among them, the outer cover layer 2' has a front part 201' covering the abdomen side of the wearer, a rear part 202' covering the back side of the wearer, and a crotch part 203' provided between the front part and the rear part. The front part 201' and the rear part 202' overlap each other and are flat-angled. The lateral edges of the front part 201' and the rear part 202' join with each other along the longitudinal direction to form a first joint part 6'. The first joint part 6 ′ makes the front portion 201 ′ and the rear portion 202 ′ together form a waist opening shape, which respectively extend from the upper end to the lower end of the two lateral edges.

[0065] The crotch portion 203' is provided with a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com