Pipe pile double production line circulating water production line and production method

A production method and production line technology, applied in the field of pipe pile double production line circulation production line, can solve the problems of increased lifting times, large investment, hidden safety hazards, etc., and achieve the effects of improving installation efficiency, simplifying the process flow, and being safe and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

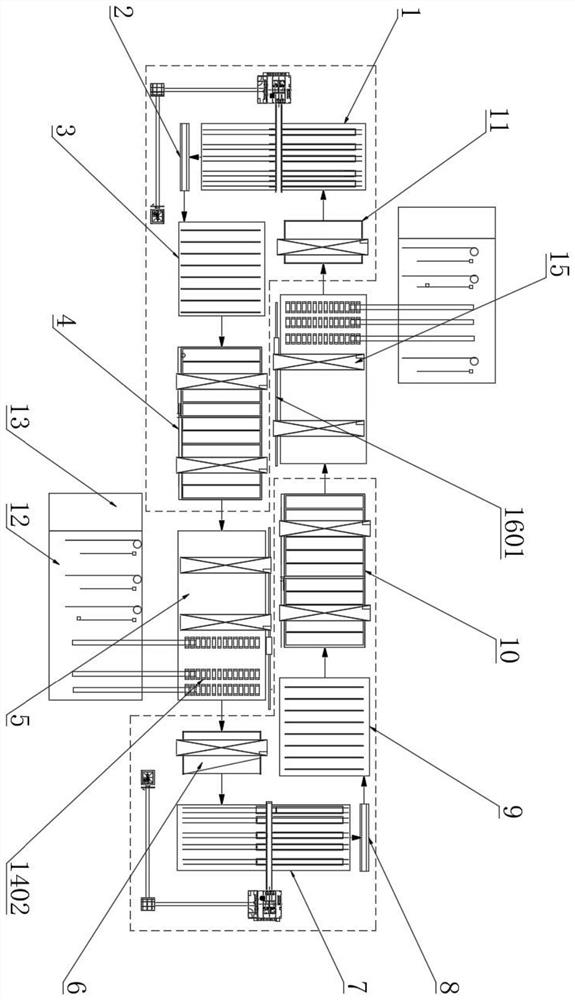

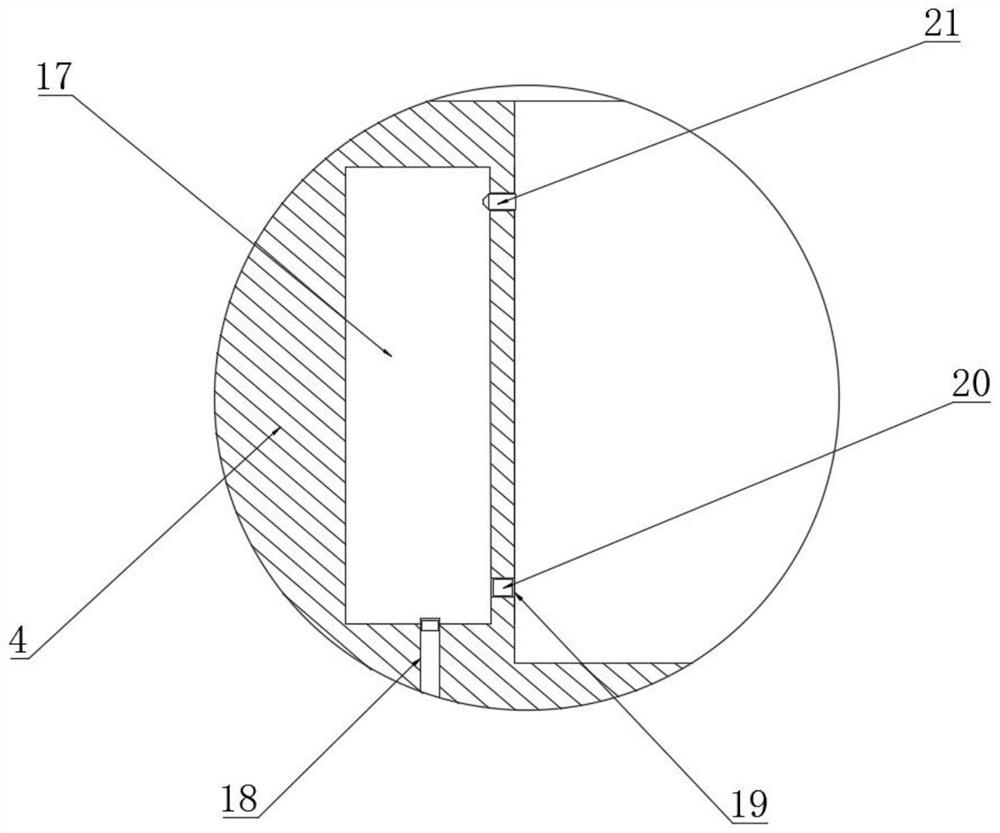

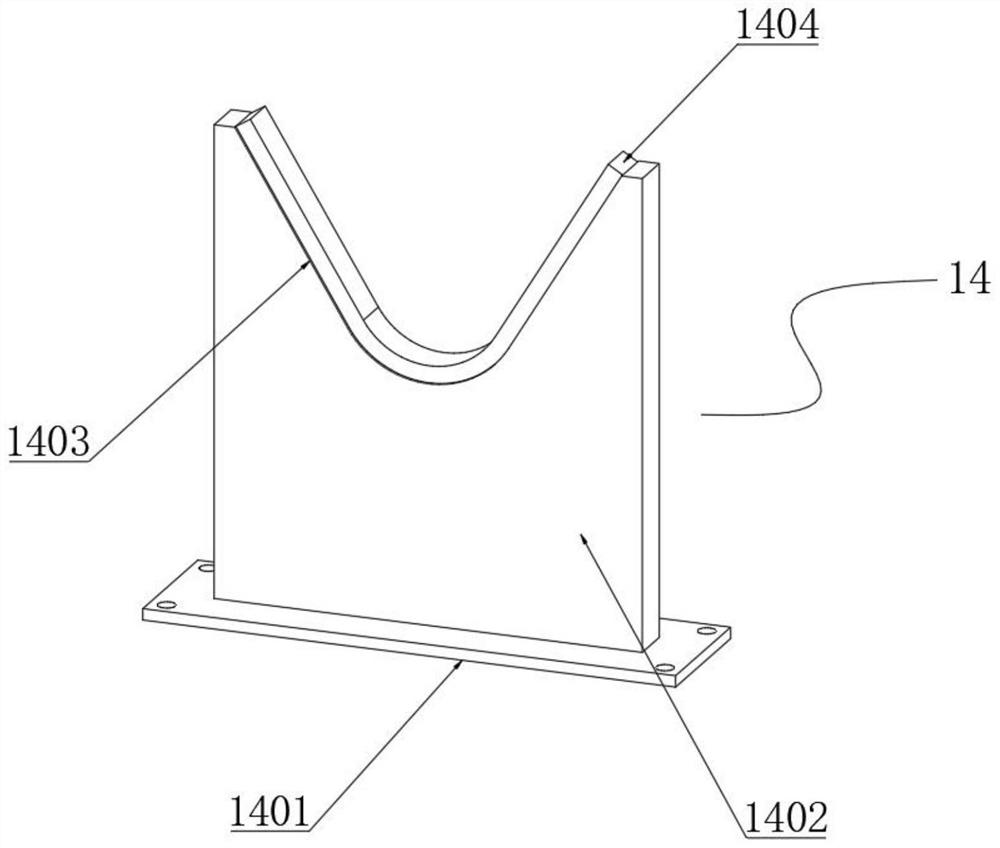

[0042] Example 1: as Figure 1-4 As shown, the present invention provides a technical solution, the pipe pile double production line circulating water production line includes a first distribution area 1, a first tension area 2 is provided on one end of the first distribution area 1, and the first tension area is 2. One side is provided with the first centrifugal zone 3, one side of the first centrifugal zone 3 is provided with the first steaming zone 4, and one side of the first steaming zone 4 is provided with the disassembly zone 5, which is located in the first steaming zone 4-1. The side of the disassembly area 5 is provided with a second mold frame area 6, one side of the second mold frame area 6 is provided with a second cloth area 7, and one side of the end of the second cloth area 7 is provided with a second tension area 8 , a second centrifugal zone 9 is provided on one side of the second tensioning zone 8, a second steaming zone 10 is provided on one side of the sec...

Embodiment 2

[0054] Example 2: as Figure 1-5 As shown, the present invention provides a technical solution, the pipe pile double production line circulating water production line includes a first distribution area 1, a first tension area 2 is provided on one end of the first distribution area 1, and the first tension area is 2. One side is provided with the first centrifugal zone 3, one side of the first centrifugal zone 3 is provided with the first steaming zone 4, and one side of the first steaming zone 4 is provided with the disassembly zone 5, which is located in the first steaming zone 4-1. The side of the disassembly area 5 is provided with a second mold frame area 6, one side of the second mold frame area 6 is provided with a second cloth area 7, and one side of the end of the second cloth area 7 is provided with a second tension area 8 , a second centrifugal zone 9 is provided on one side of the second tensioning zone 8, a second steaming zone 10 is provided on one side of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com