Automatic gluing and tiling production line for producing unit bathroom base plate

A technology of glue tiling and production line, which is applied to buildings, floors, building structures, etc., can solve the problems of uneven tiling effect, single surface decoration effect, etc., to achieve high production efficiency, ensure molding quality, and precise control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

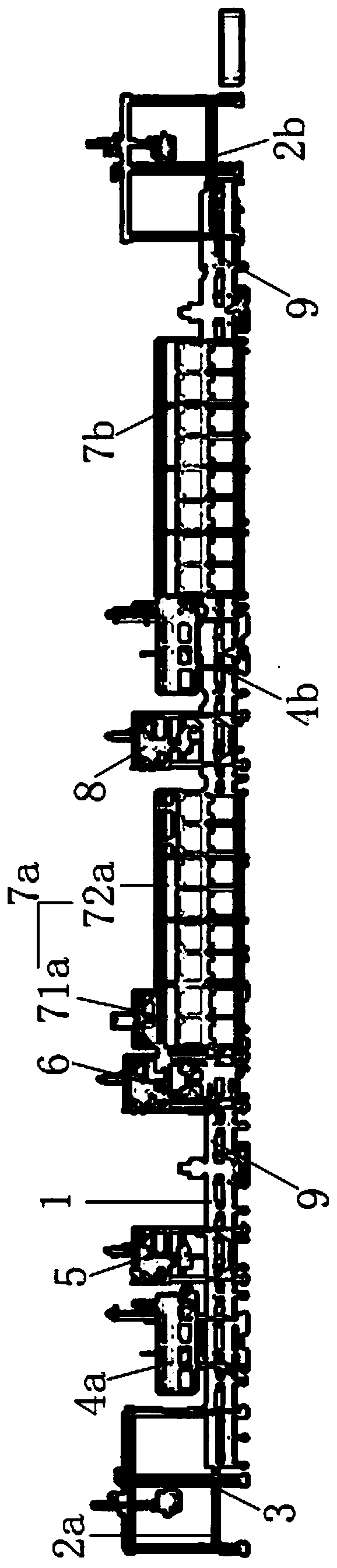

[0030] Such as Figure 1-4 As shown, an automatic gluing and tiling production line for producing integral bathroom chassis includes an assembly line 1 and a feeding module 2a, a code scanning module 3, a cleaning module 4a, a coating Adhesive module 5, tiling module 6, compaction drying module 7a, beautifying seam module 8, secondary cleaning module 4b, drying module 7b and cutting module 2b;

[0031] The loading module 2a includes a grip 21a, a servo motor connected to the grip 21a, and a pressure sensor 22a connected to the grip 21a;

[0032] The tiling module 6 includes a hoisting robot for moving floor tiles and a three-axis module for screening floor tiles, and the three-axis module is connected with the hoisting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com