A test method for waterproof performance of shield tunnel segment joints

A test method and technology of segment, applied in liquid/vacuum measurement for liquid tightness, application of stable tension/pressure to test material strength, measurement of fluid acceleration and deceleration rate, etc. The complex working state of the gasket, the deviation of the waterproof test structure of the gasket, etc., can improve the test efficiency and the test data is reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The patent of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the patent of the present invention is not limited to the following embodiments.

[0038] Now in conjunction with above-mentioned each accompanying drawing example, further set forth the present invention.

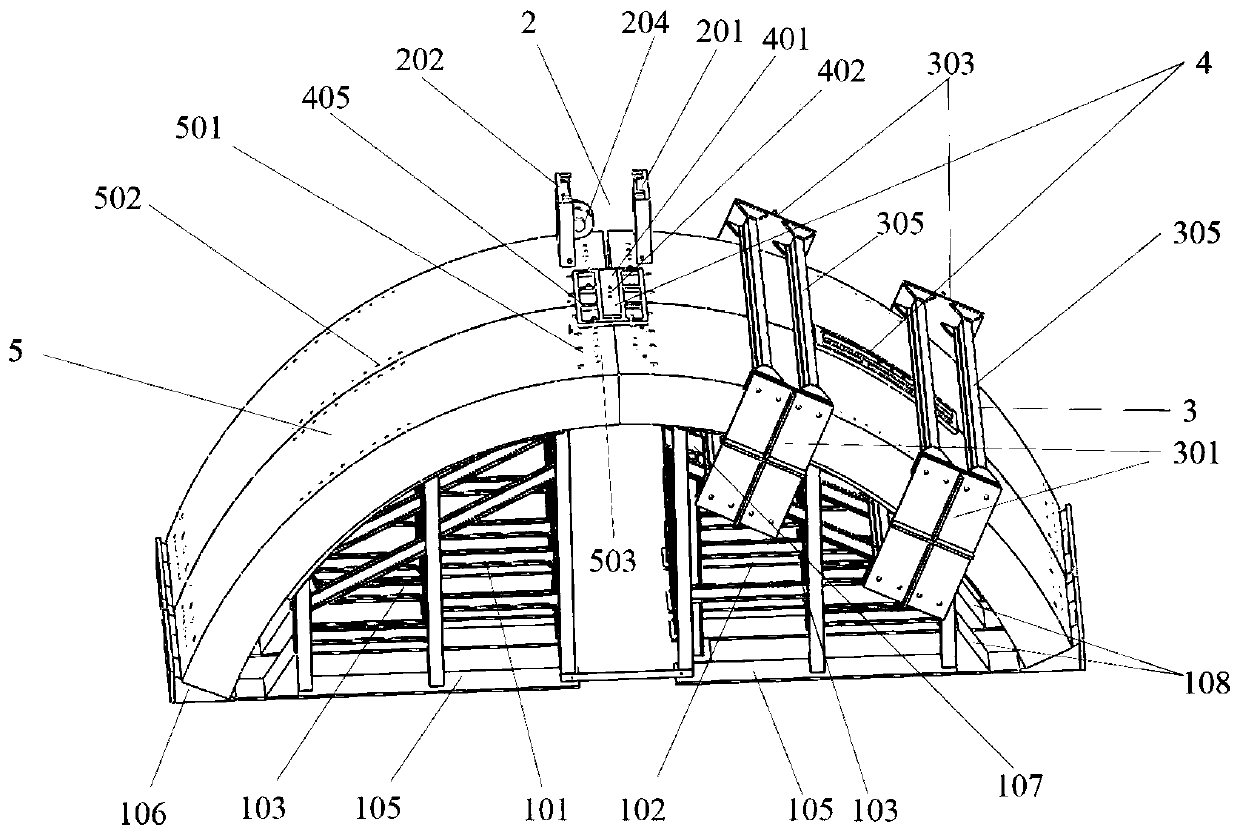

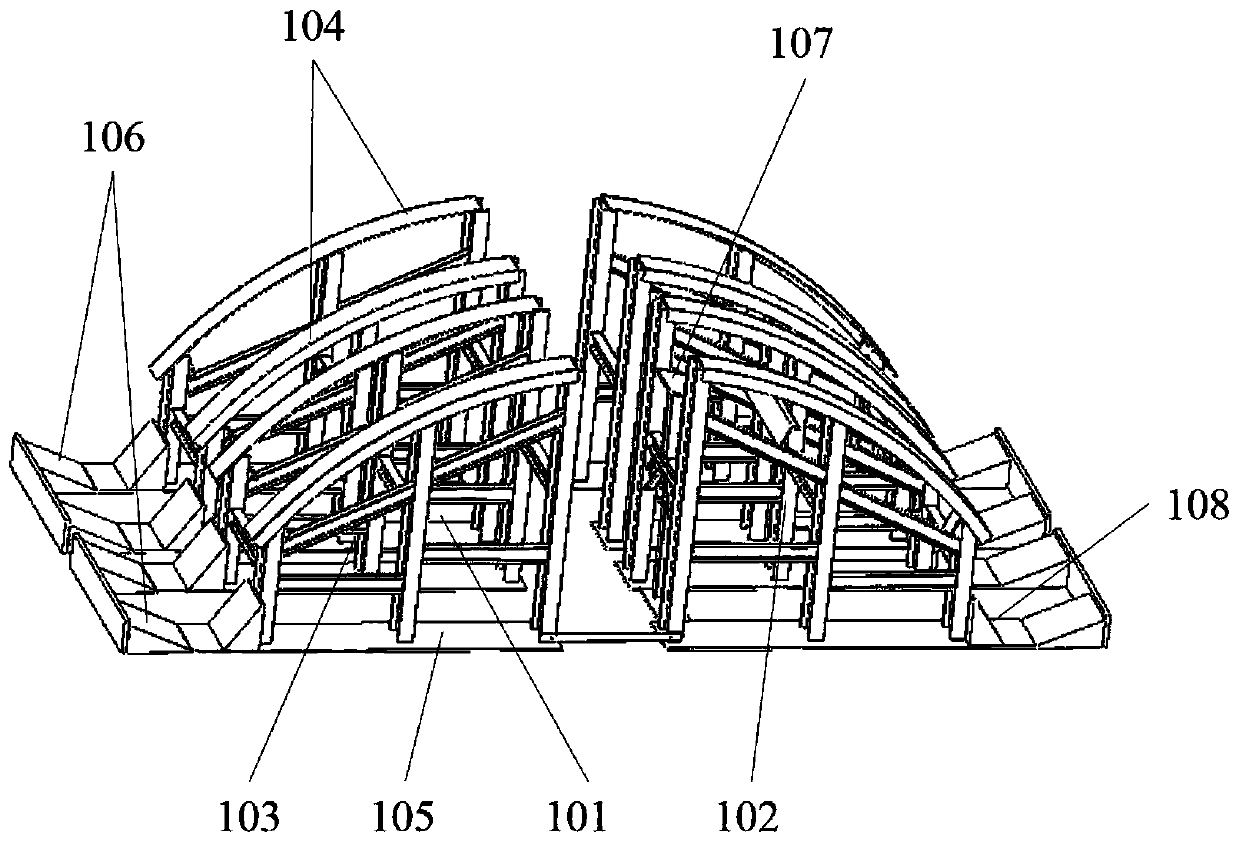

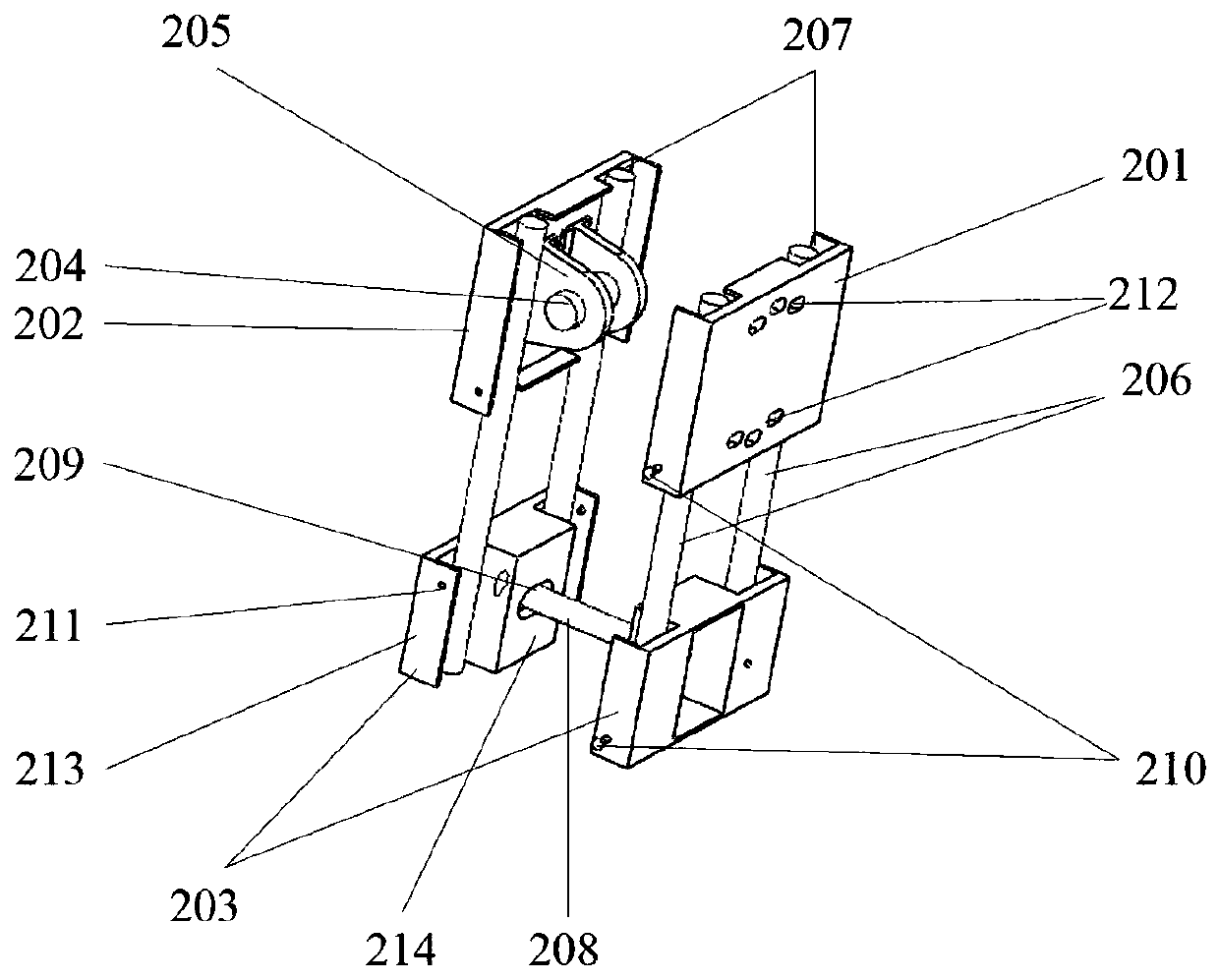

[0039] Such as figure 1 As shown, the shield tunnel segment seam waterproof performance test equipment of the present invention is mainly used for the waterproof performance test of the elastic rubber gasket under the conditions of different openings and staggered joints of the full-size segment model. The test equipment includes : fixed segment support frame 101; movable segment support frame 102; combined steel frame 103; curved st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com