Horizontal vibration isolation suspension for non-highway vehicle seat

A technology for off-highway vehicles and seats, applied in the direction of seat suspension devices, etc., can solve the problems of inability to achieve low-frequency vibration isolation, complex structure, and low excitation frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

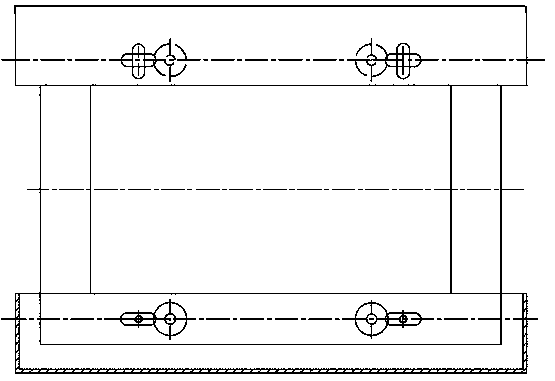

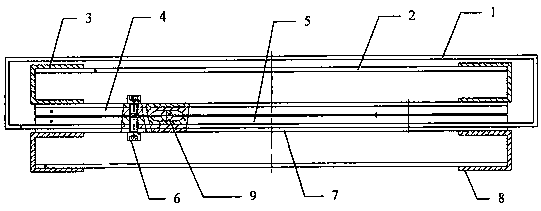

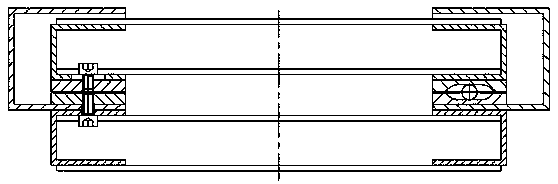

[0013] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, this embodiment includes a limiting device 1, a long U-shaped plate on the upper base plate 2, a short U-shaped plate on the upper base plate 3, a long U-shaped plate on the lower base plate 7, a short U-shaped plate on the lower base plate 8, an upper damping plate 4, The lower damping plate 5, steel ball 9 and screw 6, the long U-shaped plate 2 of the upper bottom plate and the upper damping plate 4 are connected by screws 6, the long U-shaped plate 7 of the lower bottom plate, the limiting device 1 and the lower damping plate 5 are connected by screws 6, there is a groove on the contact surface of the upper damping plate 4 and the lower damping plate 5, and the steel ball 9 is placed in the groove, and the upper damping plate 4 and the lower damping plate 5 on each side Among the two grooves, there are four grooves in total, and the steel ball 9 can move horizontally in the grooves. This structure c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com