All-weather SUV radial tire

A radial tire, all-weather technology, applied to tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve problems such as insufficient braking performance and decreased wear resistance, so as to improve rigidity and improve braking Performance, improved snow and off-road traction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

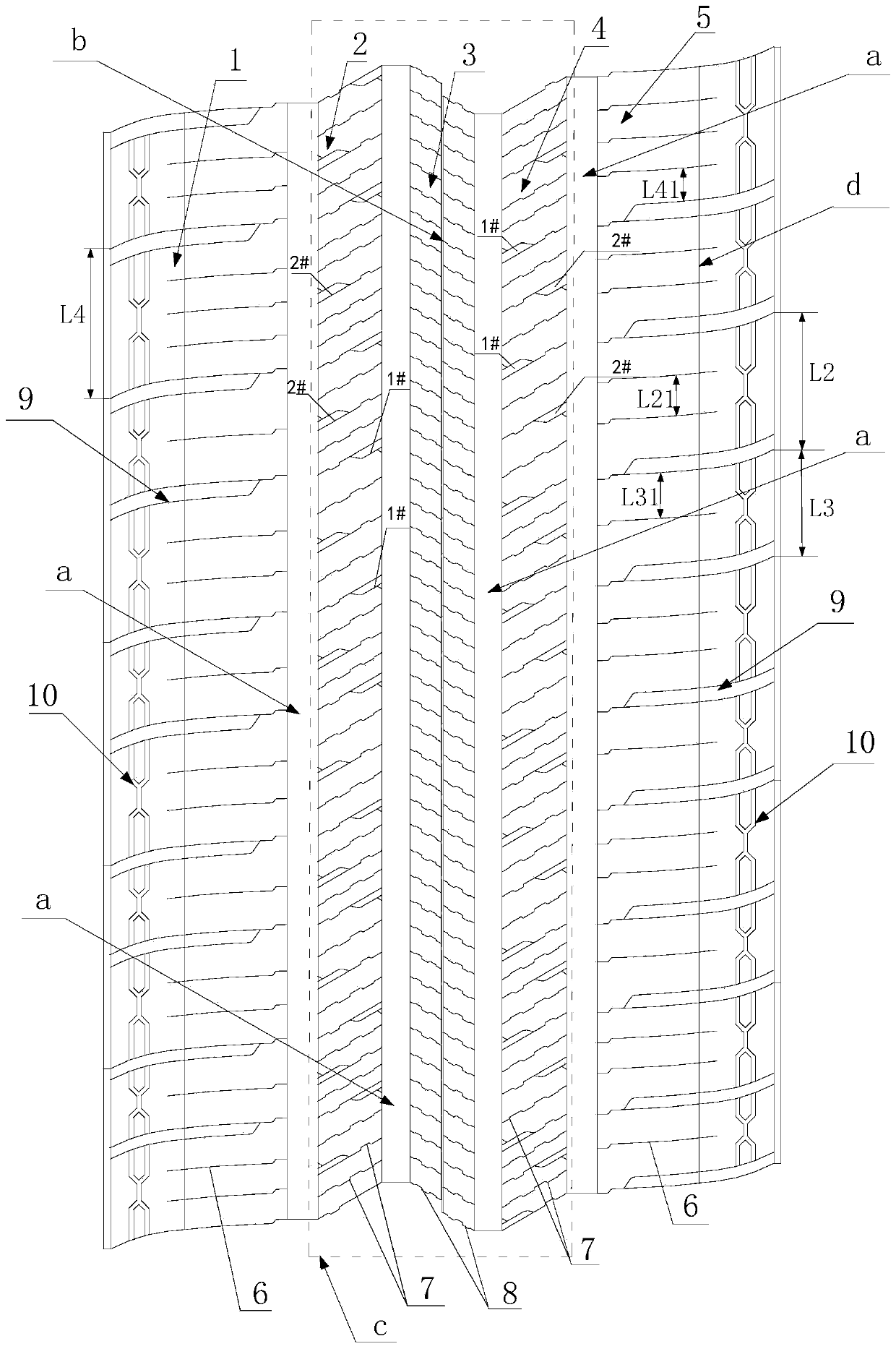

[0029] In order to understand the above-mentioned purposes, features and advantages of the invention more clearly, the invention will be further described below in conjunction with the accompanying drawings and embodiments. figure 1 The direction shown prevails.

[0030] Such as figure 1 As shown, the present invention proposes an all-weather SUV radial tire. Four vertical straight grooves a are arranged on the tread portion of the tire, and the four vertical straight grooves a are symmetrically distributed on both sides of the central groove b of the tread portion. b plays the role of reducing noise, and the four vertical straight grooves a divide the tread pattern from left to right into the first pattern part 1, the second pattern part 2, the third pattern part 3, the fourth pattern part 4 and the fifth pattern part. Pattern portion 5, the area surrounded by the outer edge of the second pattern portion 2 and the outer edge of the fourth pattern portion 4 is defined as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com