Composite insulator umbrella skirt unevenness aging test platform and using method thereof

A composite insulator and aging test technology, applied in the field of electric power engineering, can solve the problems of uneven aging of composite insulator sheds, uneven aging simulation, complicated slice sampling, etc., and achieve the effects of saving labor, convenient sampling, and low test cost.

Active Publication Date: 2019-06-25

STATE GRID HUNAN ELECTRIC POWER +2

View PDF10 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

During the operation, it was found that the composite insulator shed has uneven aging, that is, the shed in a certain direction will age more severely than other areas

However, when the accelerated aging of composite insulators is studied in the labor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

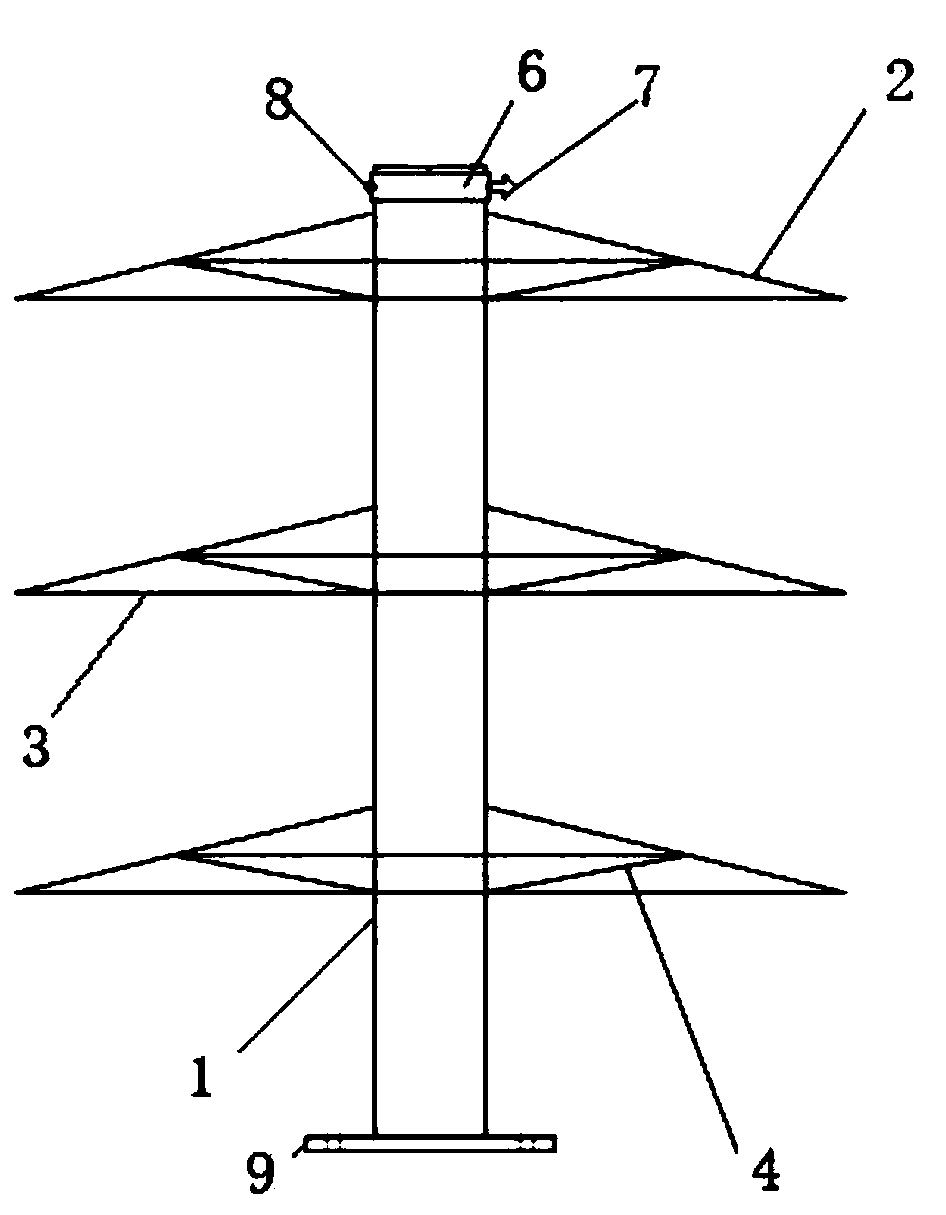

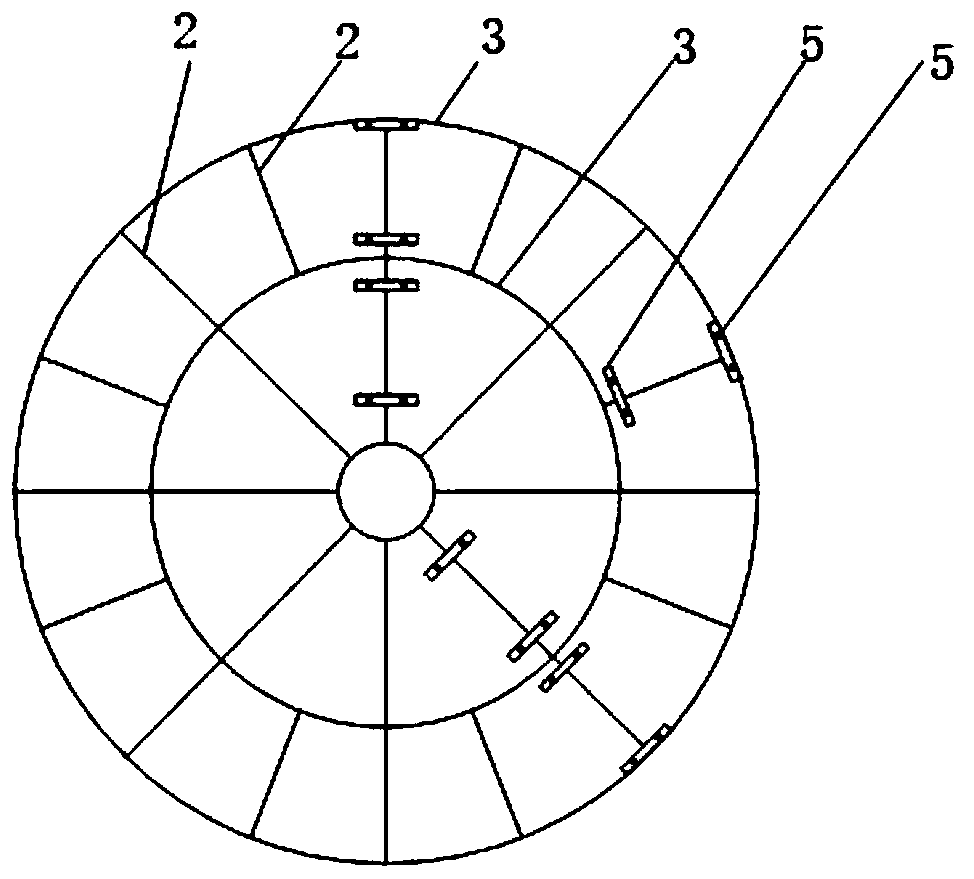

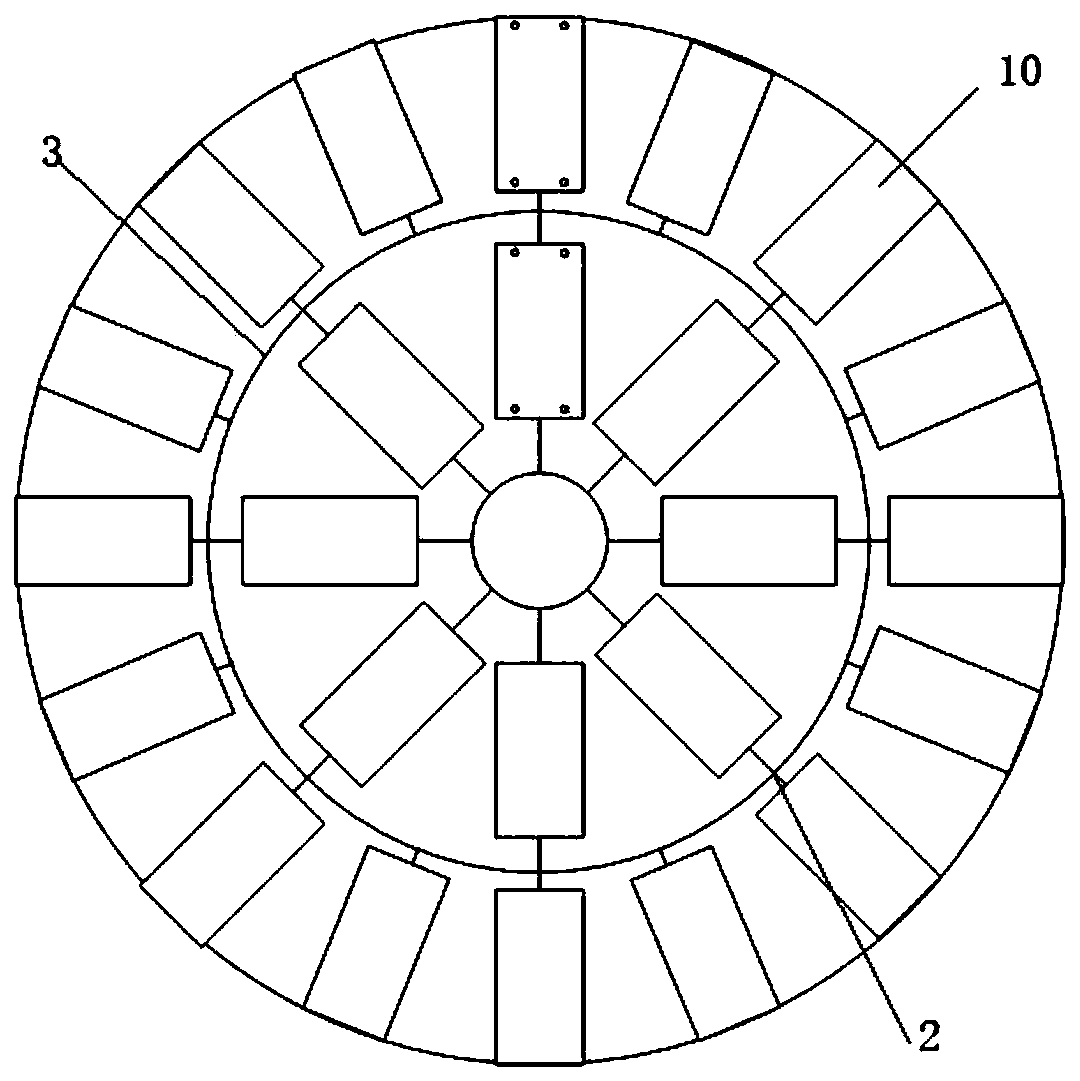

The invention discloses a composite insulator umbrella skirt unevenness aging test platform and a using method thereof. An umbrella-shaped support skeleton with the same shape and the same size as thecomposite insulator umbrella skirt is constructed, and the umbrella-shaped support skeleton is mounted on a vertical column to form a test platform; samples are evenly mounted on the outer surface ofthe umbrella-shaped support skeleton; the test platform provided with the samples is placed in an outdoor environment for aging test, a direction indicator is used to indicate the mounting directionof the test platform, and through an environmental sensor, environmental data are recorded; after a test period is reached, an umbrella-shaped support skeleton drawing is printed, the position and thedirection of a direction arrow are marked on the printed drawing on the spot, the samples are removed from the umbrella-shaped support skeleton one by one and are numbered, a sample number is filledat a corresponding position on the drawing, the samples on each layer of the umbrella-shaped support skeleton need to be filled in a drawing, and a layer number of the umbrella-shaped support skeletoncounting from top to bottom is marked closely near the drawing; and the taken sample is subjected to subsequent aging performance analysis and detection.

Description

Technical field [0001] The invention belongs to the technical field of electric power engineering, and particularly relates to a test platform for uneven aging of composite insulator umbrella skirts and a use method thereof. Background technique [0002] Composite insulators are widely used in overhead transmission lines in our country, and the aging problem cannot be ignored. During the operation, it was found that the sheds of composite insulators had uneven aging, that is, the sheds in a certain direction would age more seriously than other areas. However, when studying the accelerated aging of composite insulators in the laboratory, the aging environment of the materials is consistent, and it is difficult to simulate uneven aging, and there are problems in slicing and sampling after simulating the aging of real composite insulators. Summary of the invention [0003] This application aims to solve at least one of the technical problems existing in the prior art. To this end, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01R31/00

Inventor 巢亚锋

Owner STATE GRID HUNAN ELECTRIC POWER

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com