Coating method of lost foam

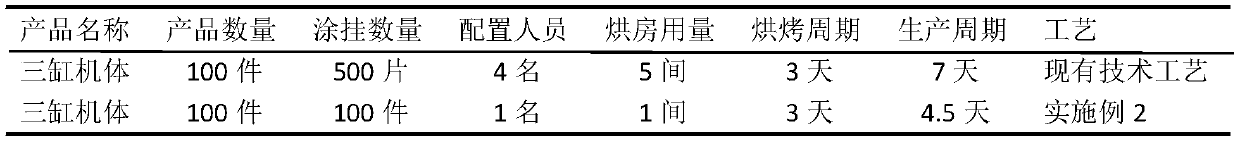

A technology of lost foam and coating, applied in the field of lost foam, can solve the problems of long time consumption, high energy consumption and high labor cost, and achieve the effect of less drying rooms, low labor intensity and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment discloses a method for coating and hanging lost foam, which includes the following steps:

[0034] Step 1. Bonding and combining multiple pieces of foam mold parts into a single casting, and reserving a first bonding surface glued to the ingate in the casting monomer, and pasting on the first bonding surface first tape;

[0035] Step 2: bonding the sprue, runner, and ingate to form a sprue assembly, and reserving a second bonding surface on the surface of the ingate to be bonded with the casting monomer, and A second adhesive tape is pasted on the second bonding surface;

[0036] Step 3, immerse and hang the casting monomer with the first tape pasted in step 1 and the runner assembly with the second tape pasted in step 2 respectively;

[0037] Step 4. Take out the casting monomer and sprue assembly after coating and hanging in step 3, and pour off the excess paint;

[0038] Step 5, drying the casting monomer and runner assembly in step 4;

[0039] Step...

Embodiment 2

[0049] like figure 1 , 2 As shown, this embodiment discloses a method for coating and hanging the lost foam of a three-cylinder body, including the following steps:

[0050] Step 1. Bonding and combining multiple pieces of foam mold parts into a single casting 1, and reserve a first bonding surface 11 glued to the ingate in the casting monomer, and place the first bonding surface 11 on the first bonding surface 11 Paste the first adhesive tape;

[0051] Step 2: bonding the sprue, runner, and ingate to form a sprue assembly, and reserving a second bonding surface on the surface of the ingate to be bonded with the casting monomer, and A second adhesive tape is pasted on the second bonding surface;

[0052] Step 3. Submerge and hang the casting monomer 1 with the first tape pasted in step 1 and the runner assembly with the second tape pasted in step 2 respectively, and the immersion time is 2 minutes;

[0053] Step 4. Take out the casting monomer 1 and the sprue assembly afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com