Pressurizing dynamic physical interception oil smoke purification and separation device

A technology of oil fume purification and separation device, which is applied in the directions of oil fume removal, separation method, dispersed particle separation, etc., can solve the problems of potential safety hazards, assembly difficulties, and high production costs, achieve a simple structure of the fixed plate, improve smoke removal effect, and produce Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

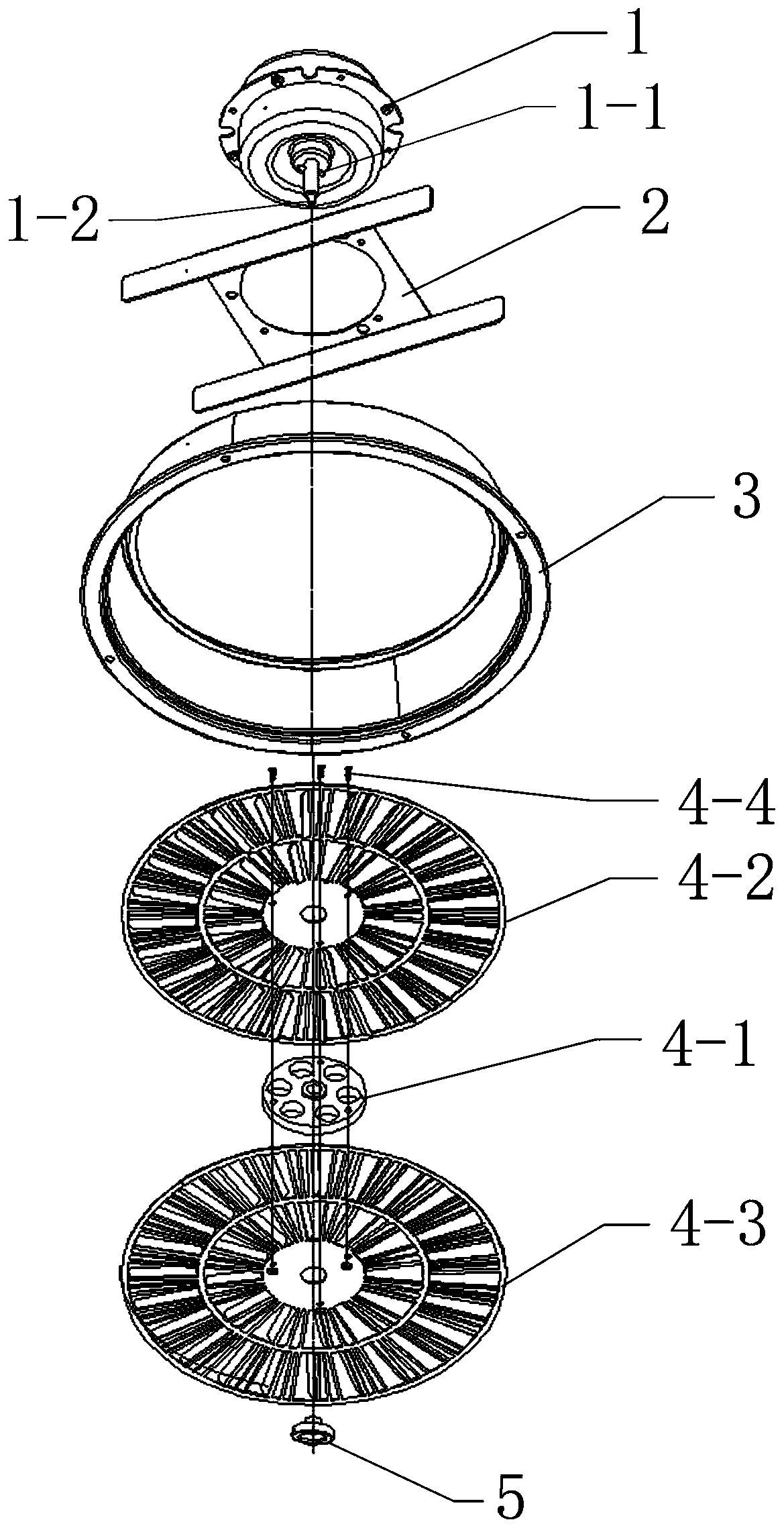

[0022] Such as Figure 1 to Figure 6 As shown, a pressurized dynamic physical interception oil fume purification and separation device includes a motor 1, a motor bracket 2, an oil pan 3, a pressurized interception assembly 4 and a nut locking member 5, and the motor bracket 2 is fixed on the The top of the oil pan 2, the motor 1 is fixed on the top of the motor bracket 2;

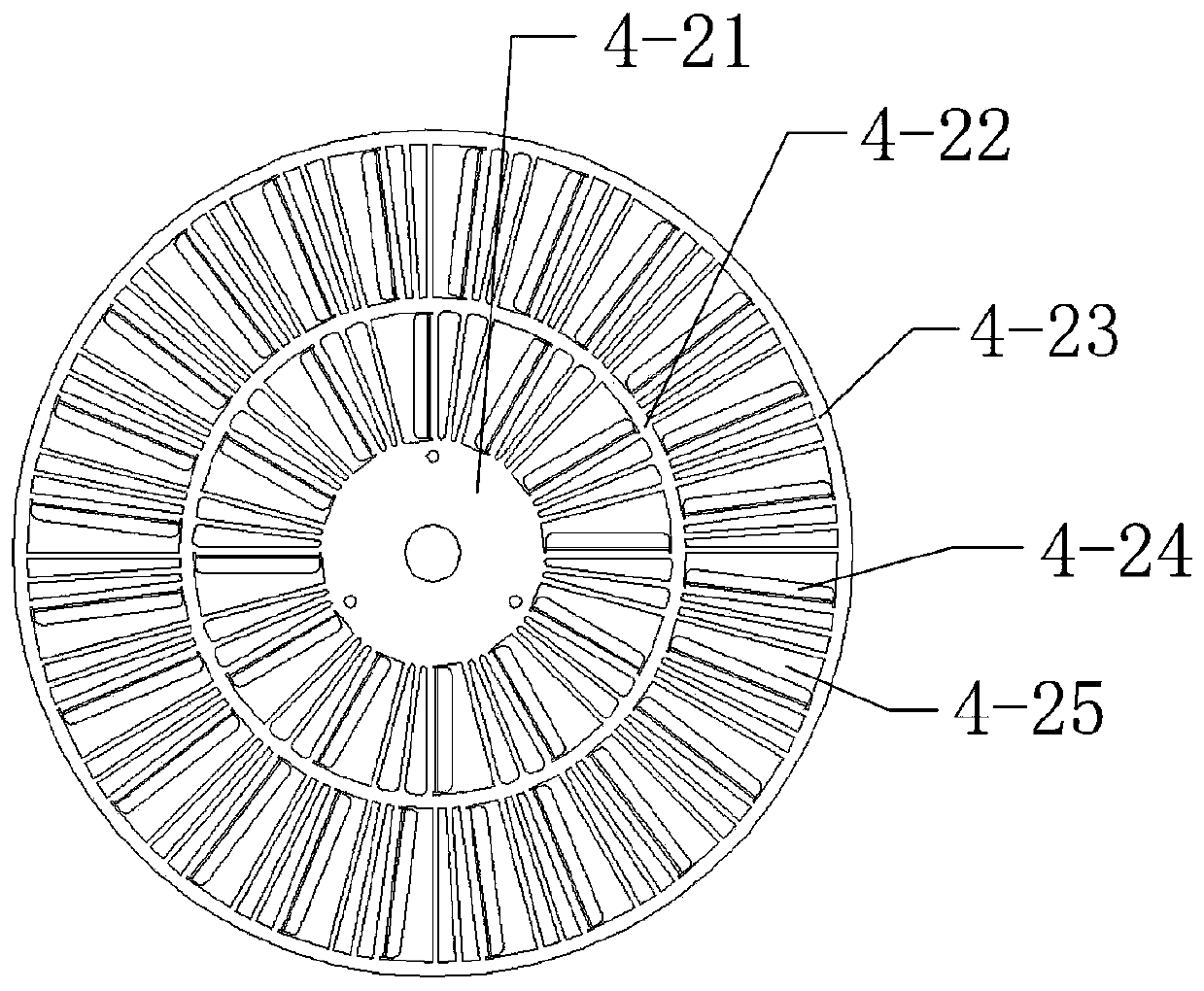

[0023] The pressurized interception assembly 4 includes a fixed seat 4-1, an upper interception plate 4-2 and a lower interception plate 4-3, and the upper interception plate 4-2 and the lower interception plate 4-3 pass through the screw nut assembly 4- 4 are respectively fixed on the upper end surface and the lower end surface of the fixed seat 4-1;

[0024] The rotating shaft of the motor 1 is provided with a clamping rod 1-1, the front end of the rotating shaft of the motor 1 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com