Prefabricated building

A prefabricated and architectural technology, applied in the direction of architecture, building components, building structures, etc., can solve the problems that the construction efficiency cannot meet the requirements of prefabricated buildings, and achieve the effects of increasing construction difficulty and construction costs, saving space, and optimizing space layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a prefabricated building, which includes

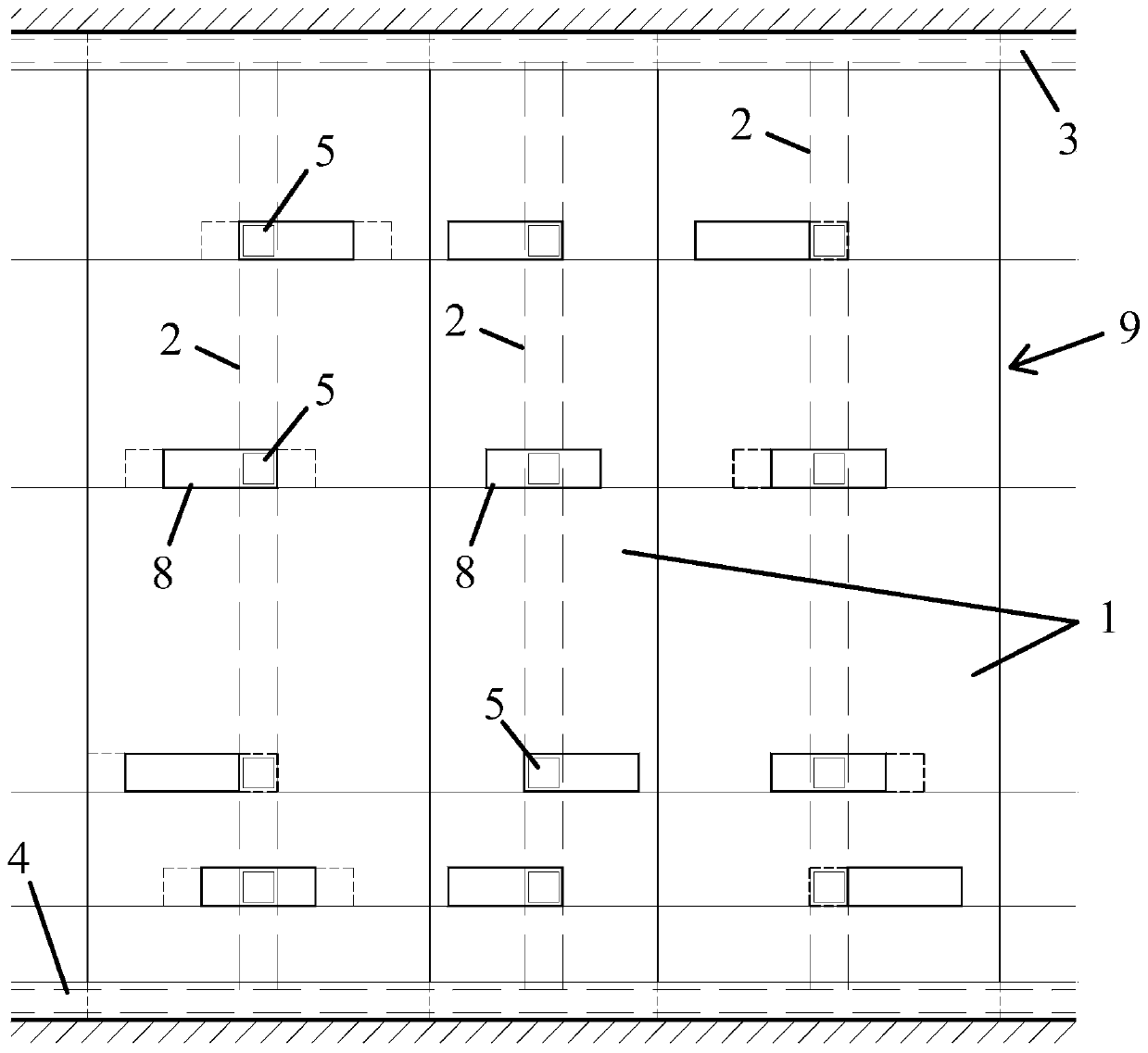

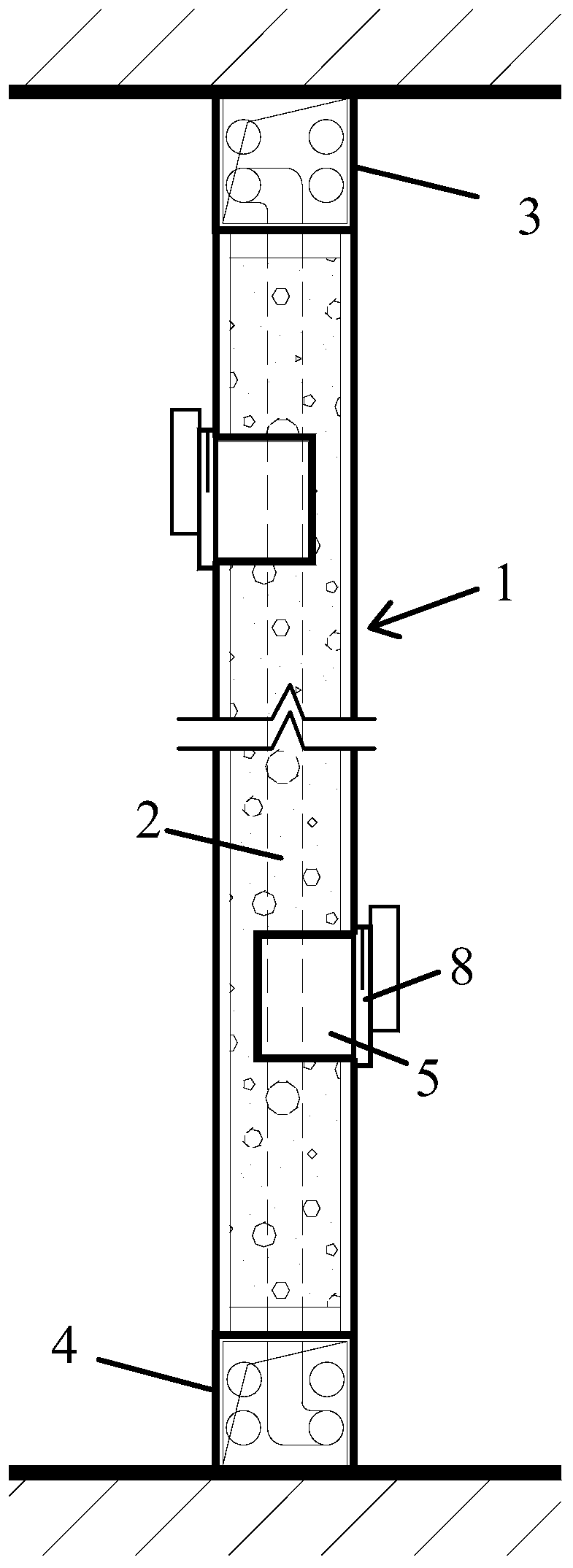

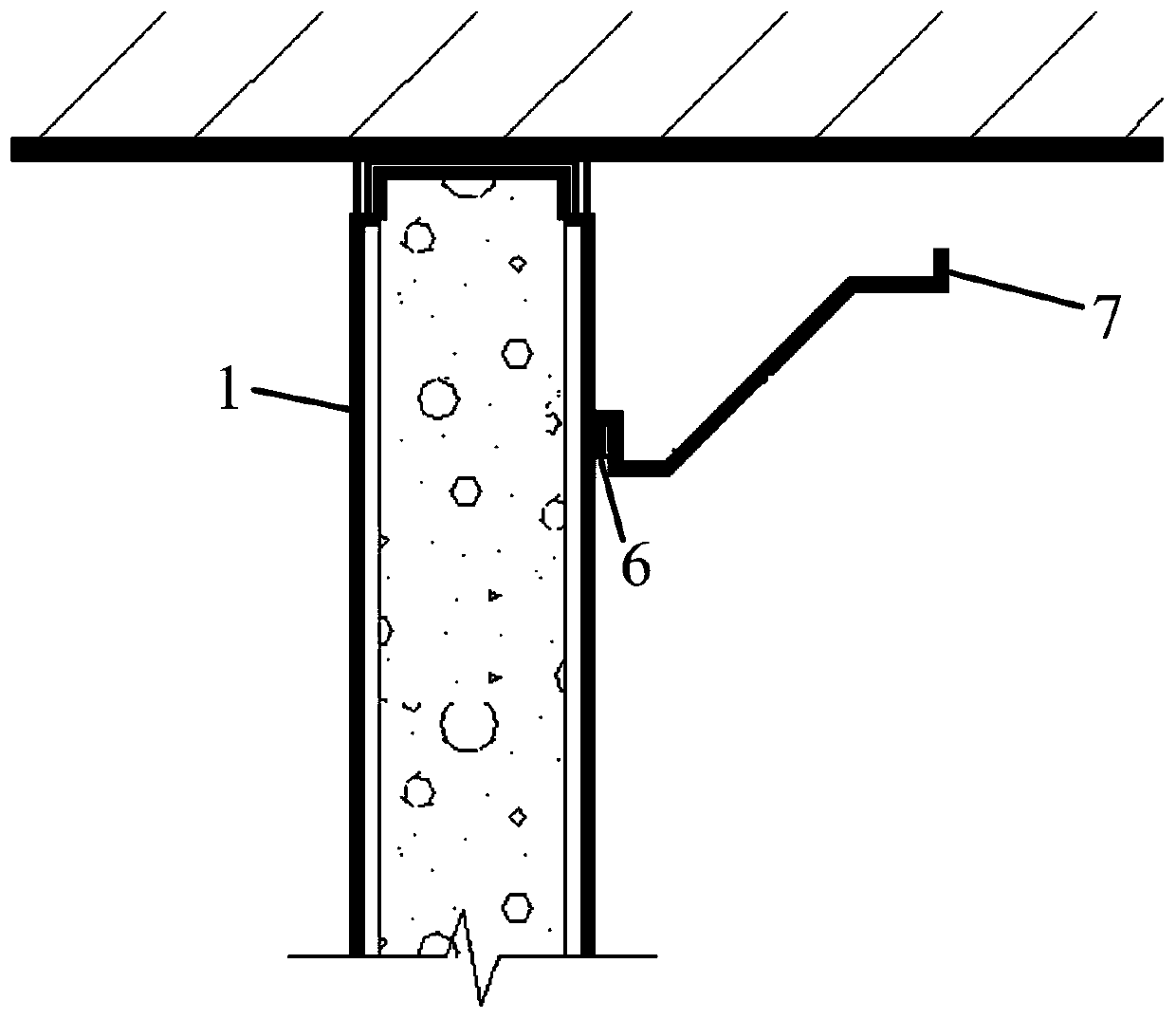

[0048] Prefabricated wall panels such as figure 1 and figure 2 As shown, it includes: a plurality of prefabricated wall components 1, the prefabricated wall components 1 are provided with at least one reserved channel 2 through which the power supply pipeline passes, and the upper and lower ends of the reserved channel 2 respectively extend to the house The roof and the ground are respectively connected with the upper pipeline channel 3 located on the roof and the lower pipeline channel 4 located on the ground. At least one external power point interface 5, by reserving a reserved channel for the power supply pipeline to pass through when manufacturing the assembled wall component, while reserving a power point on the assembled wall component The interface 5, the above-mentioned reserved channel connects the upper pipeline channel and the lower pipeline channel, so that the spatial layout of the powe...

Embodiment 2

[0060] The difference between this embodiment and Embodiment 1 is that this embodiment provides a prefabricated wall component 1, such as Figure 11 As shown, the connecting surfaces of the two adjacent fabricated wall components 1 are planes, and a plurality of fabricated wall components 1 are bonded and connected through flat openings 5 . The frame 24 is arranged at the central position of the prefabricated wall member 1 in its thickness direction. Therefore, the prefabricated wall component 1 is evenly stressed, and the strength of the prefabricated wall component 1 is further improved. Moreover, setting the frame 24 at the central position in the thickness direction of the assembled wall member 1 can also make the fillers on both sides of the frame 24 of the assembled wall member 1 the same, ensuring that the assembled wall member 1 the connection strength between them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com