Catalyst for synthesizing polyetheramine and preparation method thereof

A catalyst and polyetheramine technology are applied in the field of catalysts for synthesizing polyetheramine and their preparation, which can solve the problems of reactor material and operation safety risks, environmental hidden dangers, high reaction pressure, etc., and achieve non-explosion and environmental friendliness. The effect of improving and suppressing excessive polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

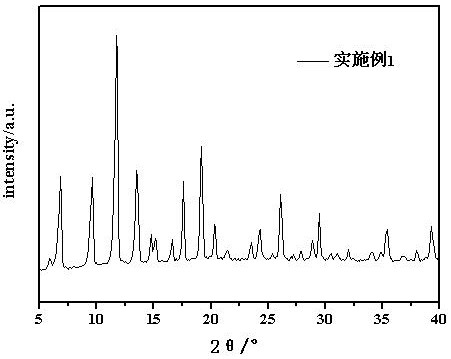

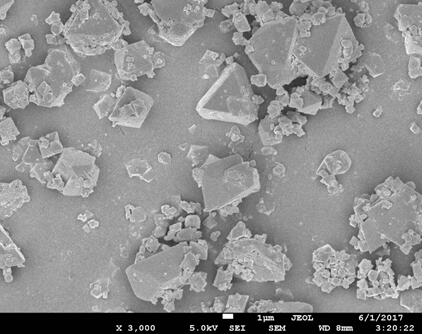

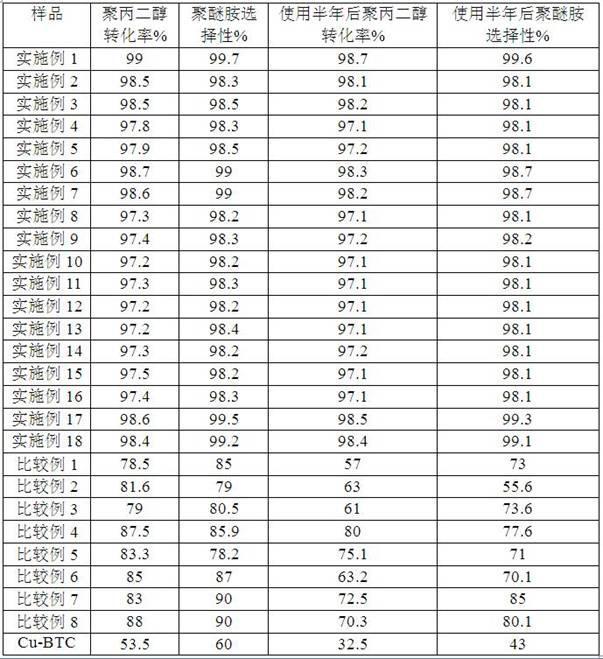

[0033] Take 1mol Cu(NO 3 ) 2 ·3H 2 O, 0.2 mol of ruthenium trichloride, 0.25 mol of lanthanum nitrate hexahydrate were dissolved in 200 mol of absolute ethanol at 65° C., and stirred at 200 rpm for 30 min to obtain a metal salt solution. Take 0.5 mol of trimesic acid, dissolve in 230 mol of N,N-dimethylformamide, stir at 200 rpm for 30 min to obtain an organic ligand solution. The organic ligand solution was added to the metal salt solution, stirred at 65°C and 260rpm for 20h, and the product was filtered after cooling down, and washed with N,N-dimethylformamide and absolute ethanol at a volume ratio of 1:1. After washing, it was placed in a room temperature environment of 25° C. to dry naturally for 10 hours, and then subjected to blast drying treatment at 150° C. for 39 hours to obtain a catalyst for synthesizing polyetheramine.

Embodiment 2

[0035] In embodiment 1, metal salt A adopts silver nitrate to replace Cu(NO 3 ) 2 ·3H 2 O, other reaction conditions and material composition remain unchanged, and a catalyst for synthesizing polyetheramine is obtained.

Embodiment 3

[0037] In embodiment 1, metal salt A adopts Cu(NO 3 ) 2 2.5H 2 O instead of Cu(NO 3 ) 2 ·3H 2 O, other reaction conditions and material composition remain unchanged, and a catalyst for synthesizing polyetheramine is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com