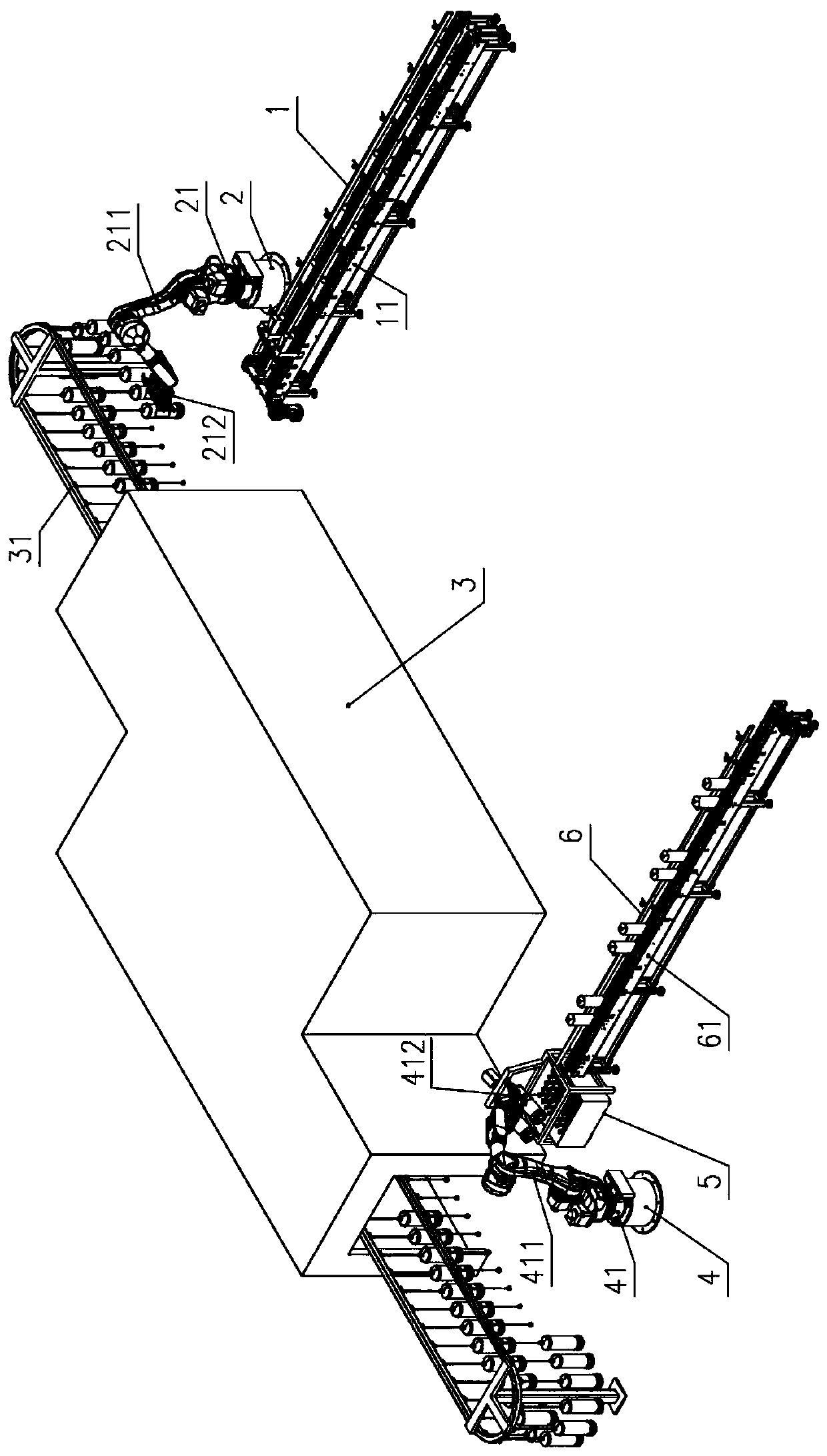

A fire extinguisher bottle automatic spraying system

A technology of automatic spraying and fire extinguisher, applied in the direction of spraying booth, spraying device, plug disassembly, etc., can solve the problems of reduced production efficiency, high labor intensity of operators, low efficiency of code retrieval, etc., and achieve the effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

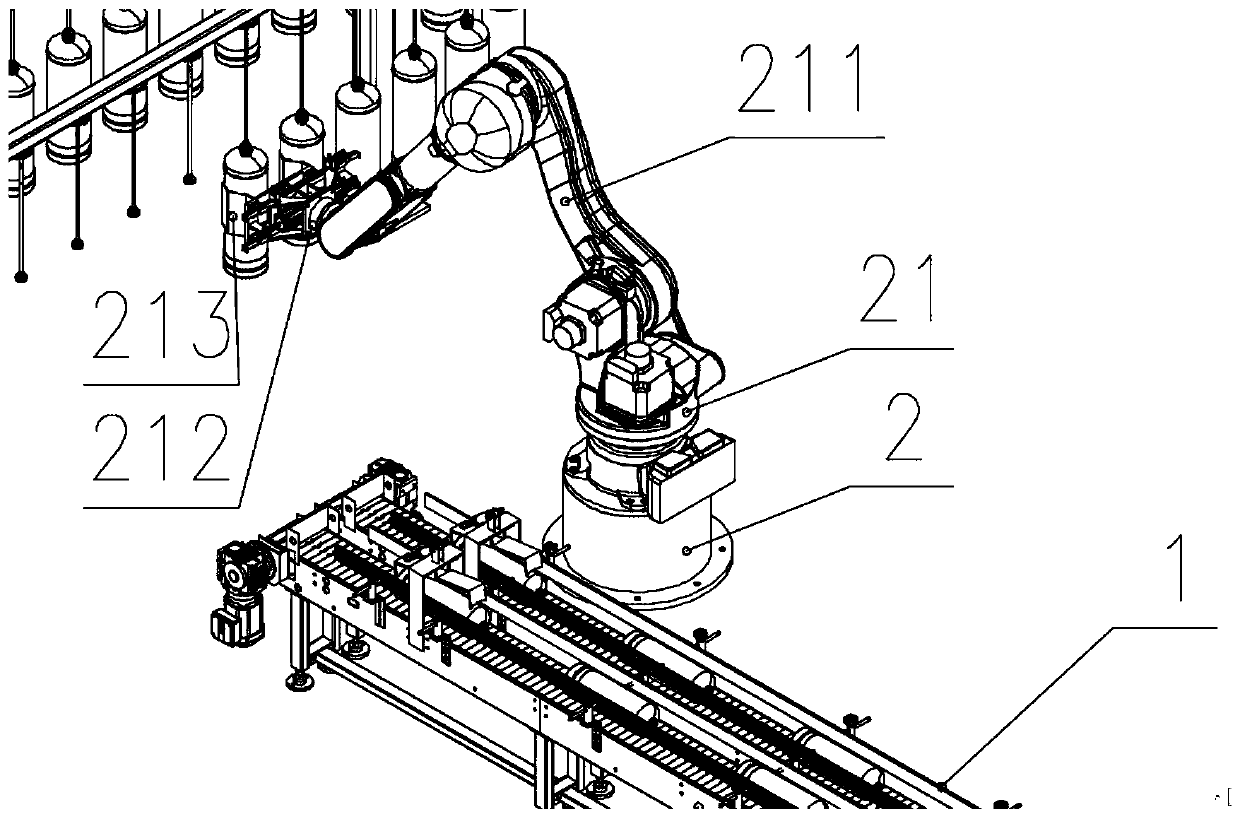

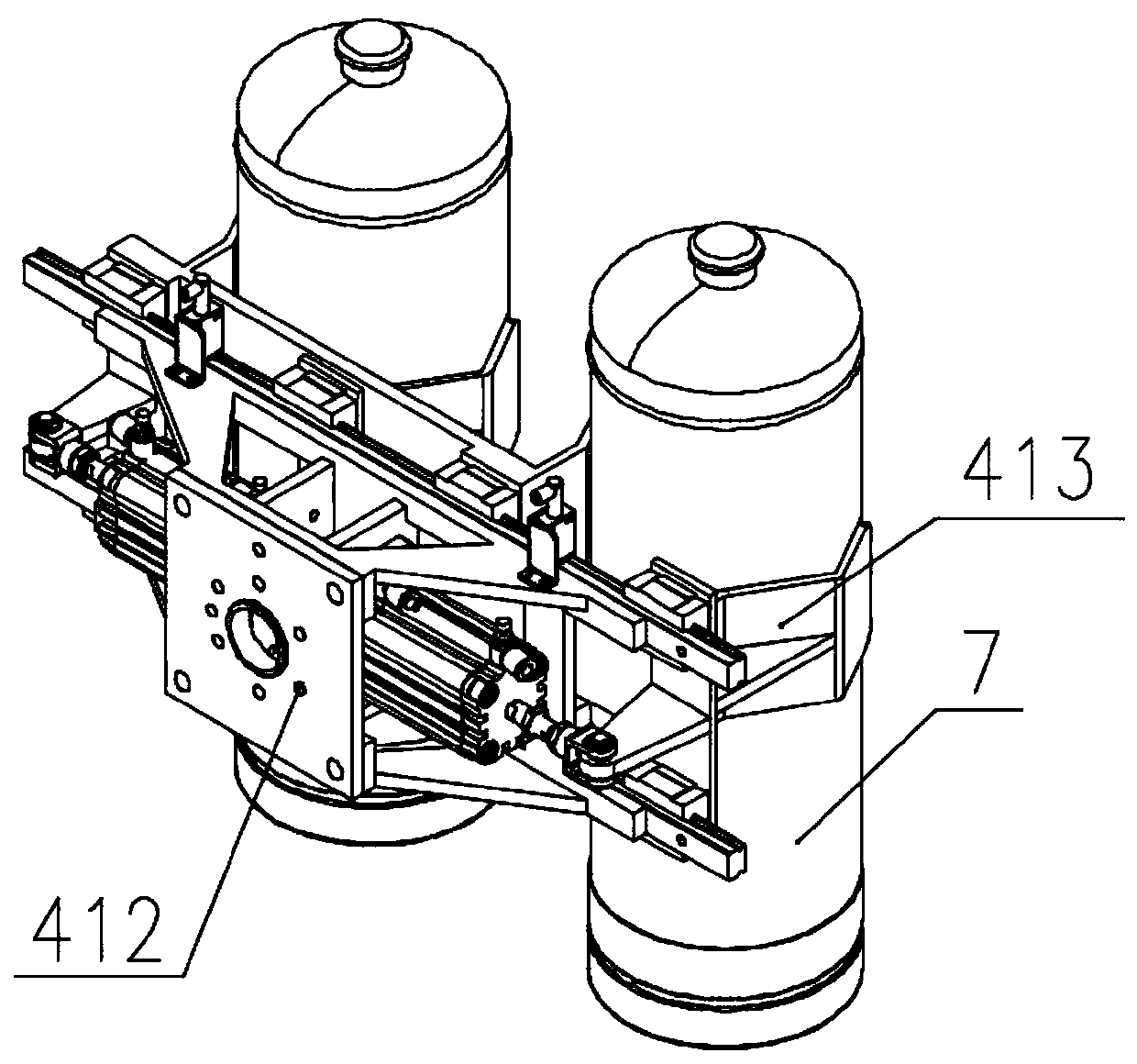

[0031] In this fire extinguisher bottle automatic spraying system, a magnetic bottle stopper 71 is installed at the mouth of the fire extinguisher bottle 7 to be sprayed, and a magnetic connector 33 is fixed at the bottom of the suspension rod 32 of the automatic spraying unit 3, which is realized by magnetic adsorption connection. The fire extinguisher bottle body 7 is connected to the suspension rod 32 of the automatic spraying unit 3, and the connection or removal of the fire extinguisher bottle body 7 and the suspension rod 32 of the automatic spraying unit 3 is realized by the robot grabbing and stacking method, which is completed by using 5 pairs of bottle cap removal units The magnetic bottle stopper 71 of the sprayed fire extinguisher bottle 7 is dismantled, and then the spraying automatic input of fire extinguisher bottle 7, automatic spraying, spraying automatic output and automatic removal of the bottle cap operation are realized. The present invention will be furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com