Method for generating acicular calcium carbonate particles

A technology of needle-shaped calcium carbonate and calcium carbonate, which is applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of slowing down the reaction speed, environmental pollution, uncontrollable calcium carbonate crystal form, etc., without changing the system temperature and reducing energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The calcium source aqueous solution used in the method for preparing acicular calcium carbonate particles disclosed in the present disclosure is not particularly limited, and water-soluble calcium salts or colloidal calcium hydroxide may be used. In a specific embodiment, the calcium source aqueous solution is calcium chloride aqueous solution. Other sources of calcium include calcium hydroxide. Likewise, carbonates that may be used include sodium carbonate and potassium carbonate.

[0031] In the method for preparing needle-shaped calcium carbonate particles disclosed in the present disclosure, the concentration of the calcium source aqueous solution and the carbonate aqueous solution is controlled, usually, the concentration of the calcium source aqueous solution and the carbonate aqueous solution is not higher than 0.05 mol / liter, In order to allow the calcium source and the carbonate solution to have suitable space and time for nucleation after contact, and to avoi...

Embodiment 1

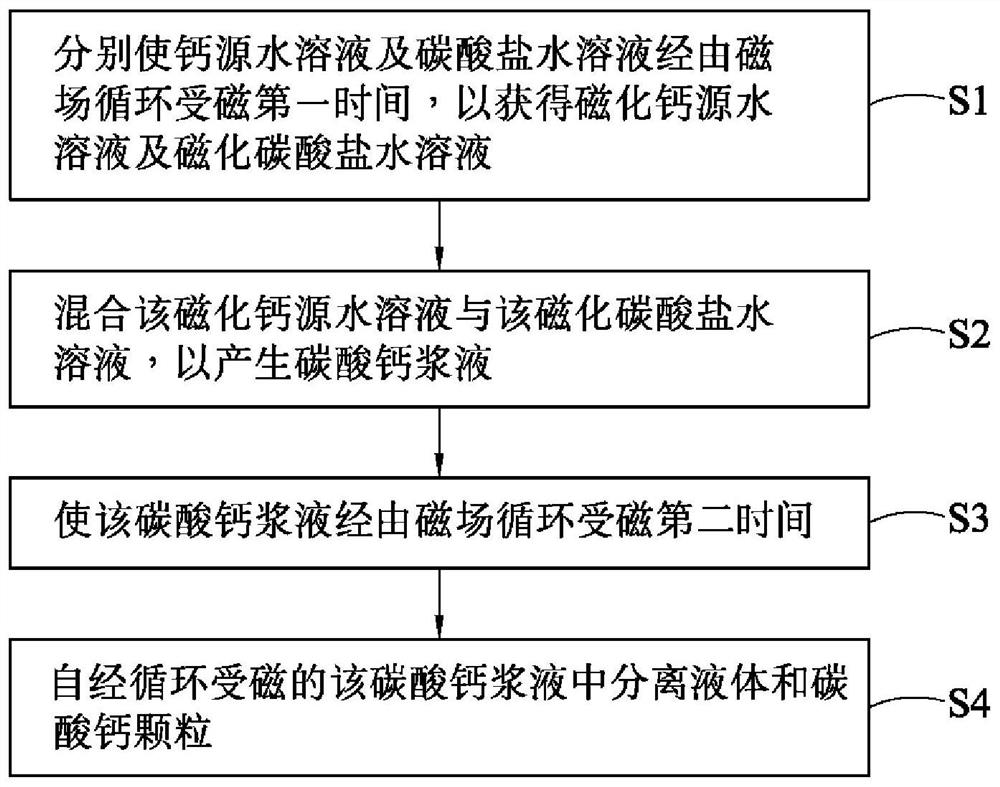

[0043] Embodiment 1: prepare calcium carbonate particle with two-stage magnetization treatment

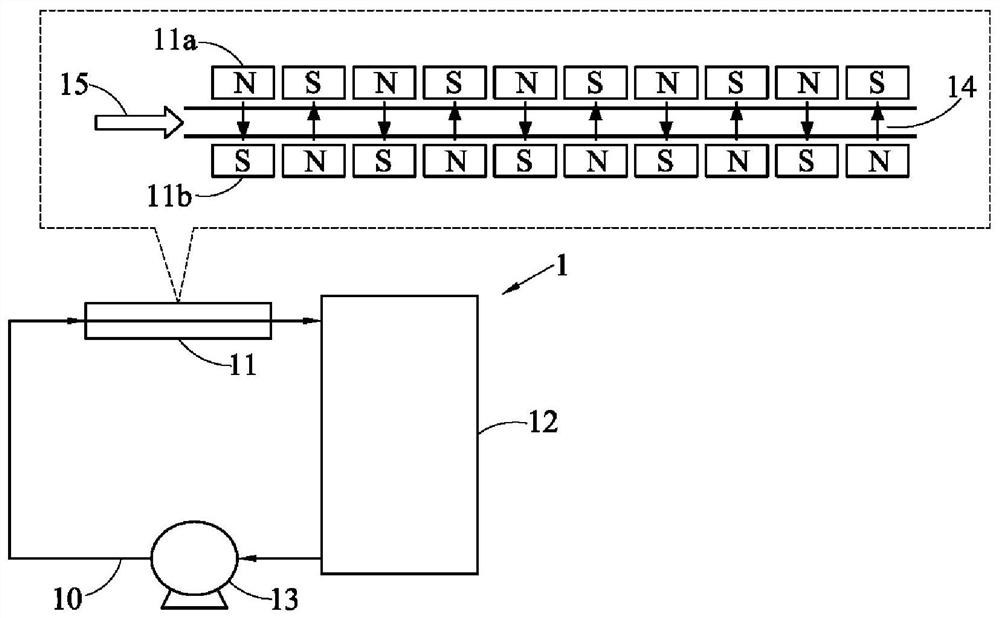

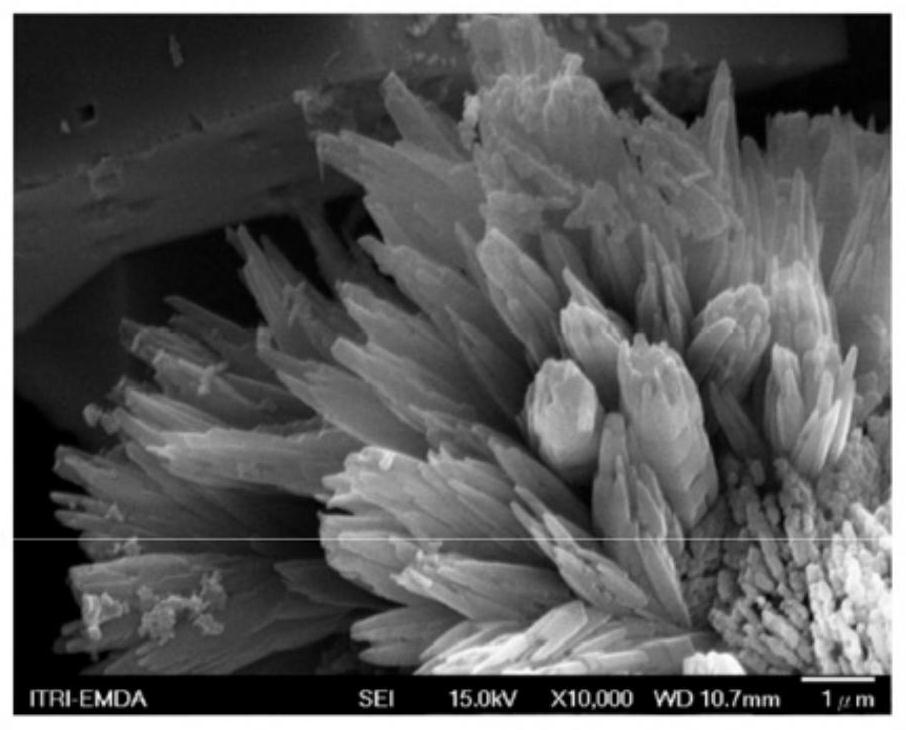

[0044] This embodiment prepares acicular calcium carbonate at a temperature of 32°C. First, prepare 0.009 mol / liter calcium chloride aqueous solution and 0.009 mol / liter sodium carbonate aqueous solution respectively, then, make the calcium chloride aqueous solution and sodium carbonate aqueous solution pass through 10 pairs of magnets, the length of which is 30 cm in total, and the resulting strength is between 7000 To 9100, the average is the magnetic field of 8145 gauss, wherein, the magnetic force direction of adjacent two pairs of magnets is opposite, and the flow velocity of setting calcium chloride aqueous solution and sodium carbonate aqueous solution through this magnetic field is 30 centimeters / second, makes calcium chloride aqueous solution and sodium carbonate aqueous solution are respectively circulated and subjected to magnetization for 4 hours to form magnetized calc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com