Method for correcting shape of complex crankshaft with large length-diameter ratio

A large aspect ratio, crankshaft technology, applied in the field of shape correction of complex crankshafts with large aspect ratio, can solve the problems of complex structure, large working load, large aspect ratio, etc., and achieves strong operability, low cost and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for rectifying the shape of a complex crankshaft with a large length-to-diameter ratio, comprising the following steps:

[0029] Step 1. Draw a line

[0030] Carry out dimensional scribing on the three-throw crankshaft with a large aspect ratio of φ160mm in the warped main journal, and record the dimensional tolerance along the axial direction as -2.5;

[0031] Step 2. Heating

[0032] The three-throw crankshaft that has completed step 1 is heated in local sections. The heating area is the three crank parts. The heating temperature of the high-temperature section is 250°C, the stress-relief aging temperature of the material 34CrNiMo6 steel, and the heating temperature of the low-temperature section is 220°C.

[0033] Step 3. Installation

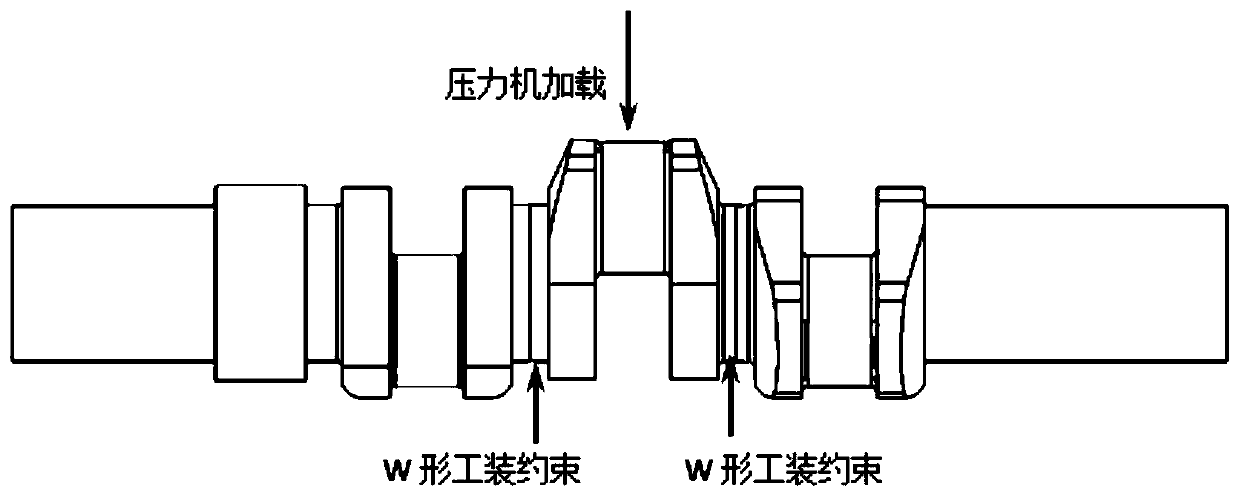

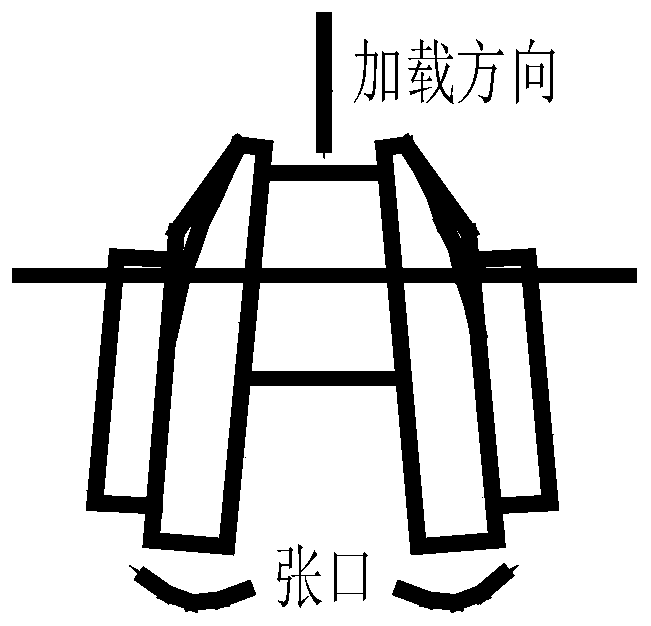

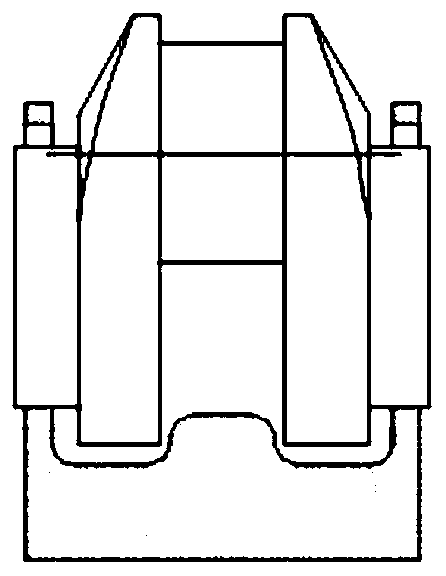

[0034] Hoist the crankshaft with three crankshafts into the form-shaping workbench, and restrain the second crankshaft with a special W-shaped tooling.

[0035] Step 4. Single point pressing

[0036] Use a mechanical pres...

Embodiment 2

[0041] A method for rectifying the shape of a complex crankshaft with a large length-to-diameter ratio, comprising the following steps:

[0042] Step 1. Draw a line

[0043] Carry out dimensional scribing on the crankshaft with a large length-to-diameter ratio of φ150mm in the warped main journal, and record the dimensional tolerance along the axial direction as -1.5;

[0044] Step 2. Heating

[0045] The five-bend crankshaft that has completed step 1 is heated in local sections, and the heating area is the third crank and the adjacent second and fourth cranks; the heating temperature of the high-temperature section is the stress relief aging temperature of the material 34CrNiMo6 steel 250 ° C, The heating temperature of the low temperature section is 220°C.

[0046] Step 3. Installation

[0047] Hoist the crankshaft with five crankshafts into the form-shaping workbench, and restrain the third crankshaft with a special W-shaped tooling.

[0048] Step 4. Single point pressi...

Embodiment 3

[0054] A method for rectifying the shape of a complex crankshaft with a large length-to-diameter ratio, comprising the following steps:

[0055] Step 1. Draw a line

[0056] Carry out dimensional scribing on the warped main journal of φ180mm four-flip crankshaft with large length-to-diameter ratio, and record the dimensional tolerance along the axial direction as -2.0;

[0057] Step 2. Heating

[0058] The four-bend crankshaft that has completed step 1 is heated in local sections, and the heating area is the second crank and the adjacent first and third cranks; the heating temperature of the high-temperature section is the stress relief aging temperature of the material 40CrNiMoA steel 250 ° C, The heating temperature of the low temperature section is 220°C.

[0059] Step 3. Installation

[0060] Hoist the crankshaft with four crankshafts into the form-shaping workbench, and restrain the second crankshaft with a special W-shaped tooling.

[0061] Step 4. Single point press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com