Vortex station

A technology of vortex and air flow, applied in the field of vortex stations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0190] Throughout the specification, the same reference numerals will be used to refer to the same features in different embodiments.

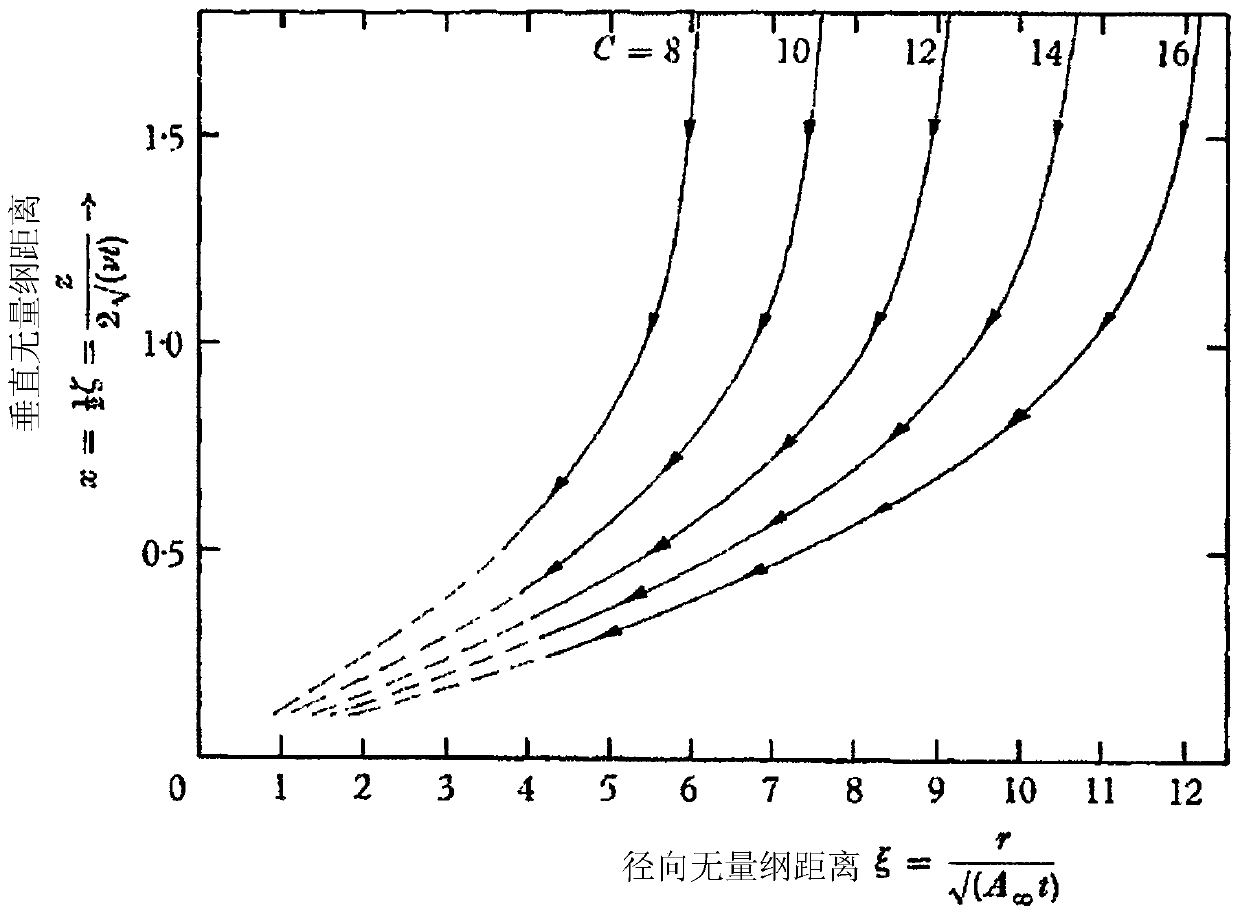

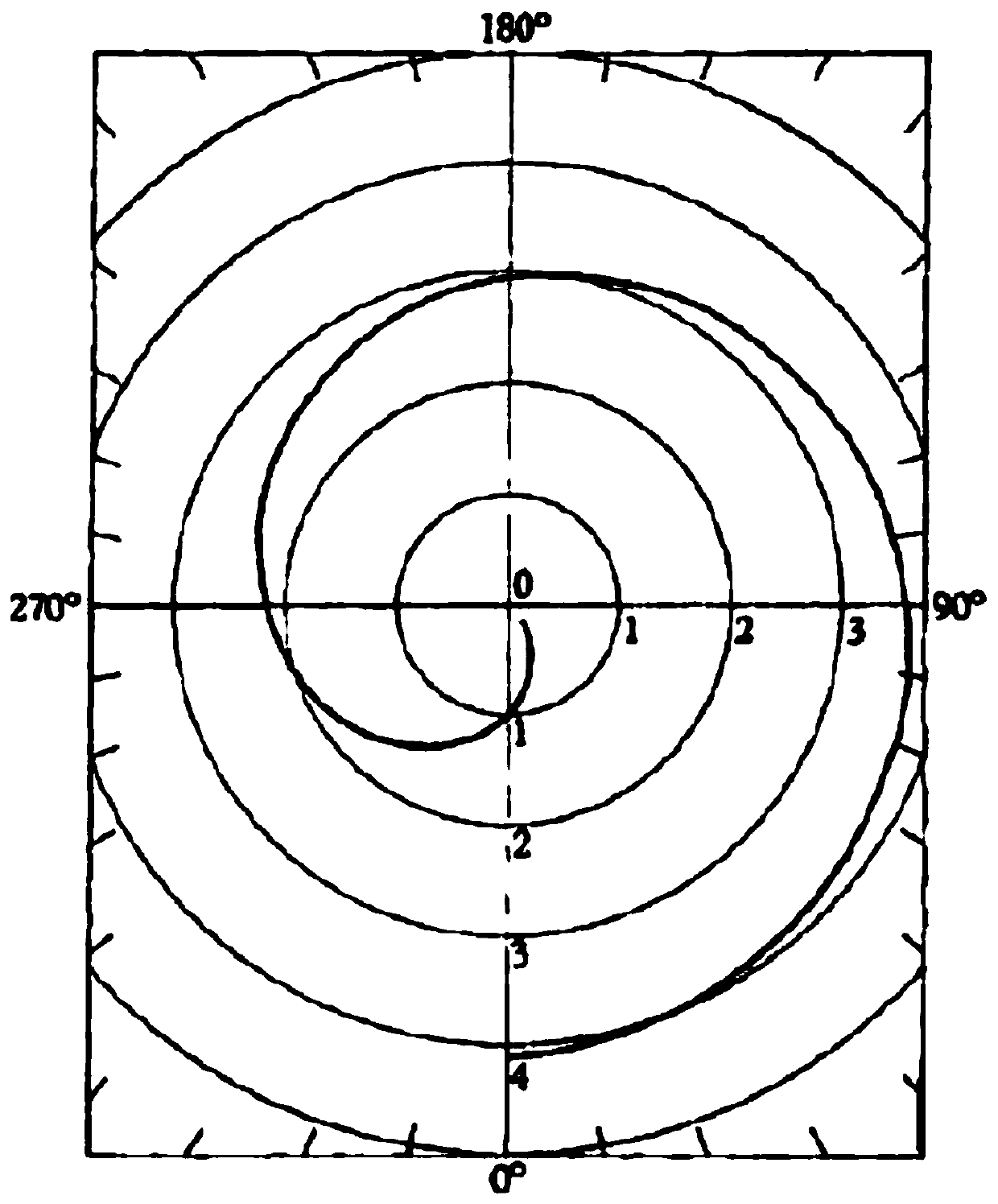

[0191] The inventors have developed improvements to traditional heat engine theory to allow improved prediction of vortex height and subsequent thermodynamic efficiency and wind speed in atmospheric buoyancy vortices by reconsidering the nature of the cold reservoir of the heat engine. Preliminary modeling suggests an economical and carbon-neutral approach to converting waste heat into electricity with an overall efficiency of about 5%. Embodiments of VCV or vortex stations capable of converting waste heat into electricity are provided and detailed below.

[0192]Because the VCV concentrates buoyancy at high wind speeds at or near ground level, the tall structures and costs of large turbines of the prior art are avoided. VCVs themselves can be very large and can be built at very low or significantly lower cost than prior art types of vortex g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com