Indirect electrohydraulic press forming tool, device and method

A technology of stretch forming and tooling, which is applied in the direction of manufacturing tools, presses, stamping machines, etc., can solve the problems that the workpiece is not allowed to be actually formed, and the punch assembly is not allowed to be moved, so as to achieve simplified radius and improved local elongation , the effect of exquisite details

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

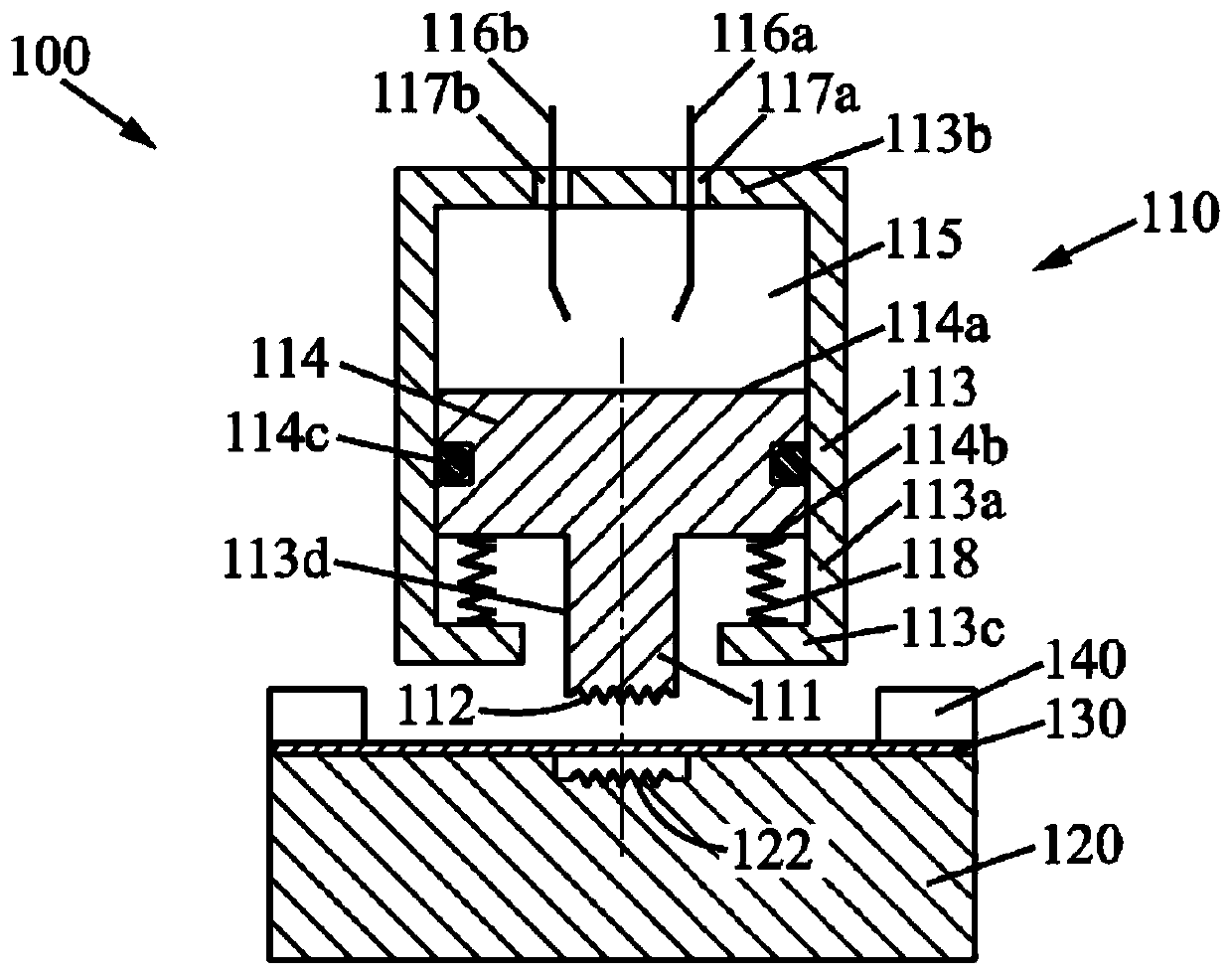

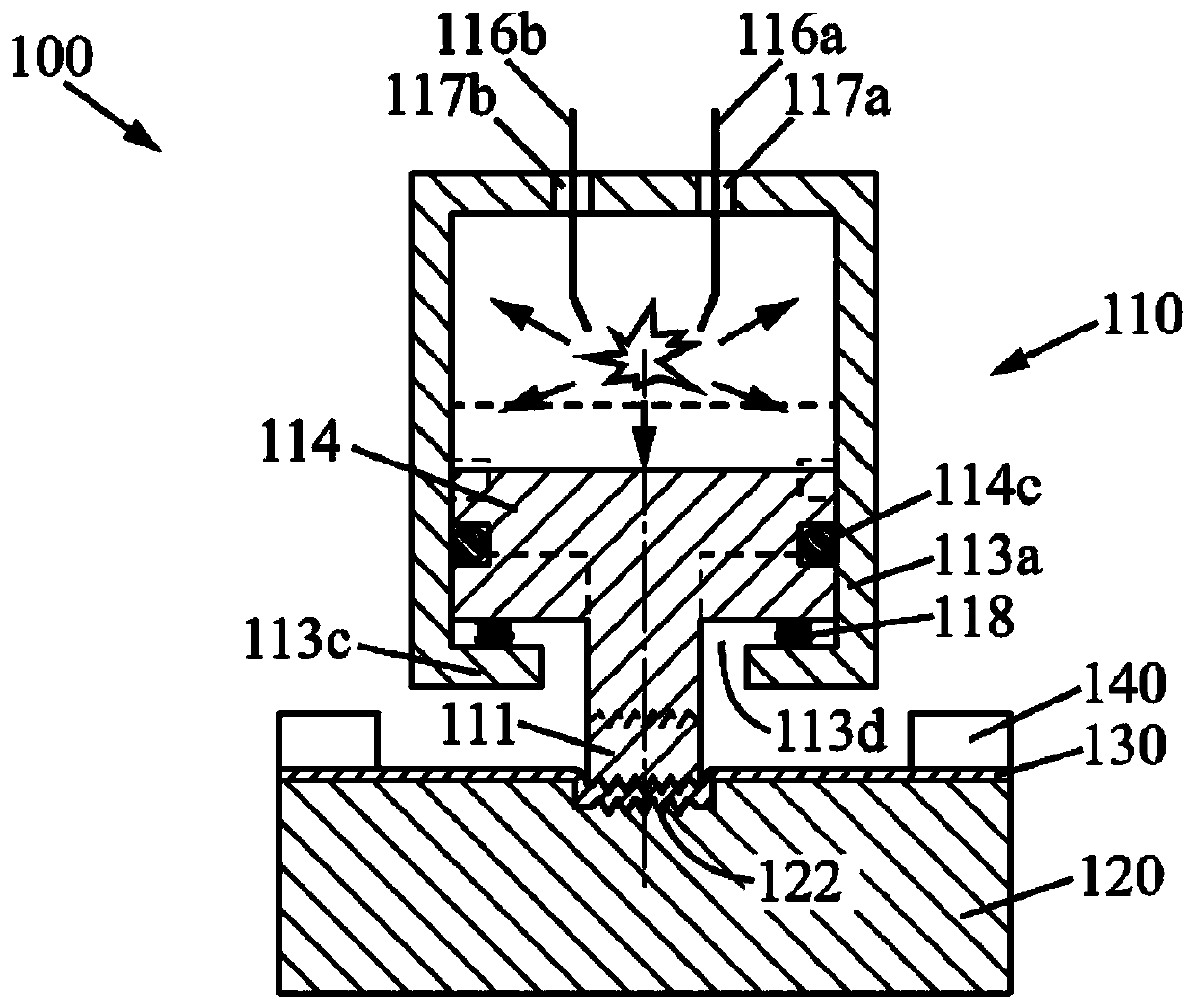

[0050] Figure 1A and Figure 1B An apparatus for indirect electrohydraulic stretch forming according to a first embodiment is shown. The device 100 for indirect electro-hydraulic stretch forming includes a tool 110 , a die 120 and a blank holder 140 . A material blank 130 to be formed, here a metal sheet, is held between the blank holder 140 and the die 120 . Binders are used to control the stretching of the blank during indirect electrohydraulic forming. The force of the blankholder is controlled to avoid wrinkles in the workpiece while at the same time enabling it to draw the material into the die, thus limiting the elongation of the material which could lead to fracture. In this embodiment, the tool 110 is above the die 120 and the blank 130 of material to be formed. The tool 110 includes a male die 111 having a general shape complementary to that of the female die 120 so that the male die 111 is inserted into the female die 120 while accommodating the thickness of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com