Granulating chicken-feeding device

A technology of granulation box and granulation knife, which is applied in feed, grain processing, poultry industry, etc., can solve the problems of high cost, inability to process corn, soybean and rice processing and granulation, expensive chicken raising equipment, etc., and achieve cost Low cost, simple structure, and the effect of reducing procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

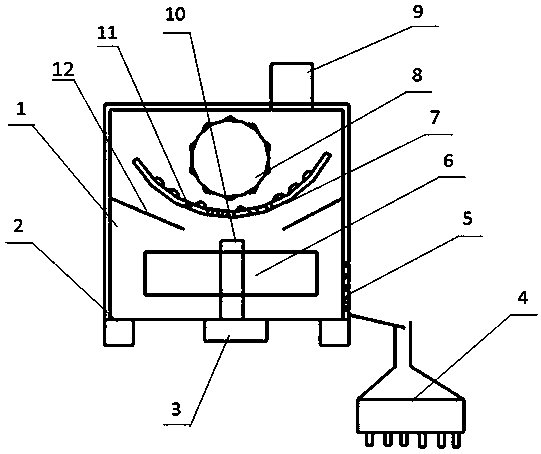

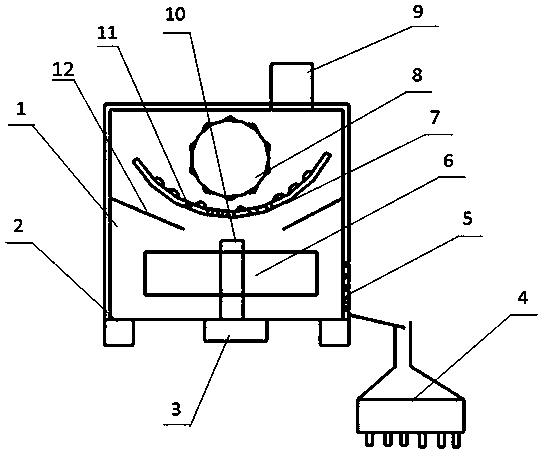

[0019] Embodiment 1: as figure 1 As shown, a chicken feeding device for granulation; comprises a granulation box 1 and a granulator 4; the granulation box 1 is fixed on the frame 2; the top of the granulation box 1 is provided with a feeding port 9; The feed inlet 9 is set on the right side of the granulation box 1; the bottom of the granulation box 1 is provided with a motor 3; the motor 3 is arranged in the middle of the bottom of the granulation box 1; the granulation box 1 is provided with a grinding roller 8 , Grinding wall 7, guide plate 12, granulating shaft 10 and granulating knife 6; The grinding roller 8 is provided with grinding teeth; The grinding wall 7 is arranged below the grinding roller 8; The grinding wall 7 is provided with There are the same grinding teeth as on the grinding roller 8; the guide plate 12 is arranged on the inner wall of the granulation box 1 and placed below the grinding wall 7; the granulation shaft 10 is connected to the granulation knife ...

Embodiment 2

[0025] Example 2, such as figure 1 As shown, a chicken feeding device for granulation; comprises a granulation box 1 and a granulator 4; the granulation box 1 is fixed on the frame 2; the top of the granulation box 1 is provided with a feeding port 9; The feed inlet 9 is set on the right side of the granulation box 1; the bottom of the granulation box 1 is provided with a motor 3; the motor 3 is arranged in the middle of the bottom of the granulation box 1; the granulation box 1 is provided with a grinding roller 8 , Grinding wall 7, guide plate 12, granulating shaft 10 and granulating knife 6; The grinding roller 8 is provided with grinding teeth; The grinding wall 7 is arranged below the grinding roller 8; The grinding wall 7 is provided with There are the same grinding teeth as on the grinding roller 8; the guide plate 12 is arranged on the inner wall of the granulation box 1 and placed below the grinding wall 7; the granulation shaft 10 is connected to the granulation knif...

Embodiment 3

[0031] The difference between embodiment 3 and embodiment 1 is: the granulator can be placed at the bottom of the granulation box, and the granulation knife can be placed horizontally, and the effect of granulation and classification can also be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com